Municipal construction hydraulic driven sealing plate precipitation prevention mixing device

A technology of mixing and sealing plates, which is applied to mixers with rotating stirring devices, mixers, mixer accessories, etc., can solve the problems of simple structure of mixing equipment, affecting the use of materials, poor liquid flow, etc., and achieve uniform and thorough mixing. Improve the use effect and avoid the effect of material precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

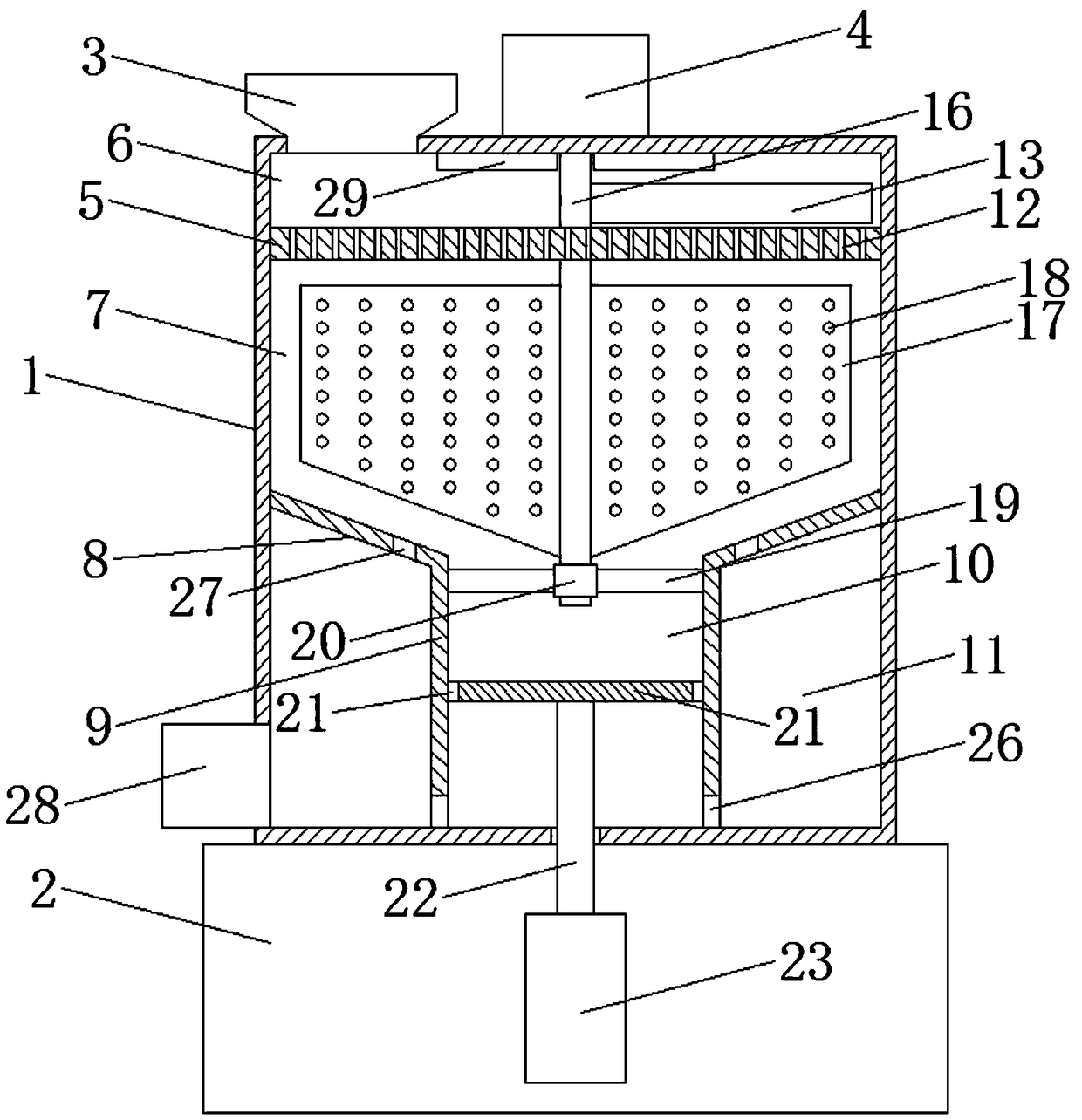

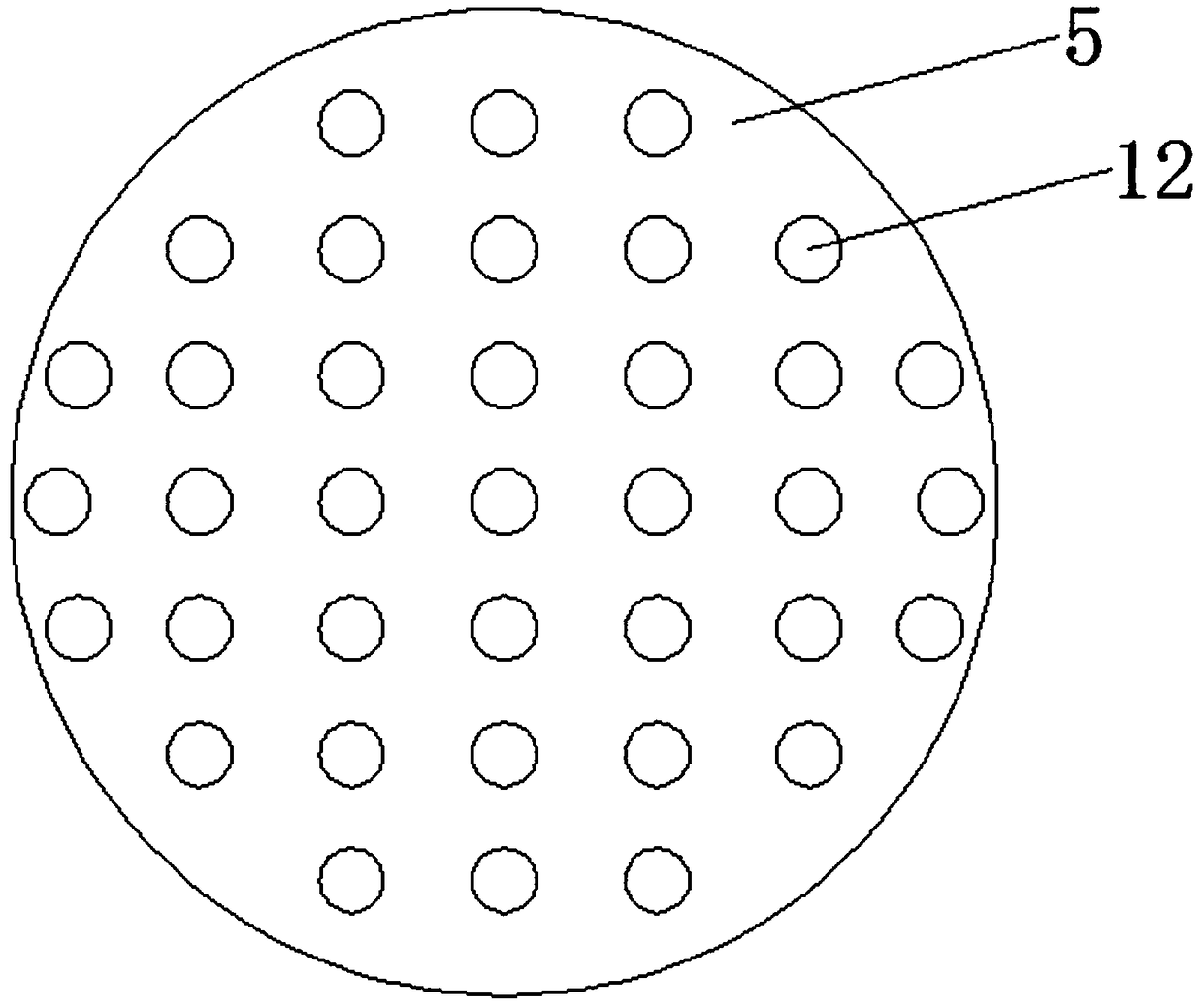

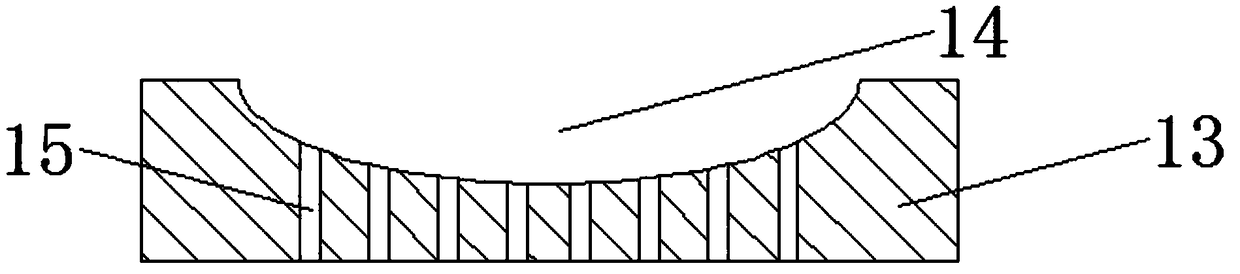

[0017] Please refer to the figure, in the embodiment of the present invention, a municipal construction hydraulic drive seal plate anti-sedimentation mixing and stirring equipment includes a housing 1, a base 2, a feeding hopper 3 and a stirring motor 4; the housing 1 is fixed on the base 2, the feed hopper 3 is connected to the top of the shell 1, and the materials that need to be stirred and mixed are sent into the shell 1 from the feed hopper 3; a horizontal blanking plate 5 and a funnel-shaped structure are fixed in the shell 1 The guide hopper 8, and the blanking plate 5 is located at the upper part, the hopper 8 is located at the lower part, the upper part of the blanking plate 5 is set as a storage chamber 6, and the lower part is set as a mixing chamber 7, and several blanking holes are opened on the blanking plate 5 12. The diameter of the feeding hole 12 is 2-3mm, and the material entered by the feeding hopper 3 is stored in the storage chamber 6, so that the material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com