A tubing suitable for foam drainage and gas recovery in highly deviated wells

A foam drainage, highly deviated well technology, applied in drilling pipes, casings, production fluids, etc., can solve problems such as affecting normal production, large pressure loss, weak liquid carrying capacity, etc., to ensure normal production capacity and reduce production. Pressure loss, uniform and thorough mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the embodiments and the accompanying drawings.

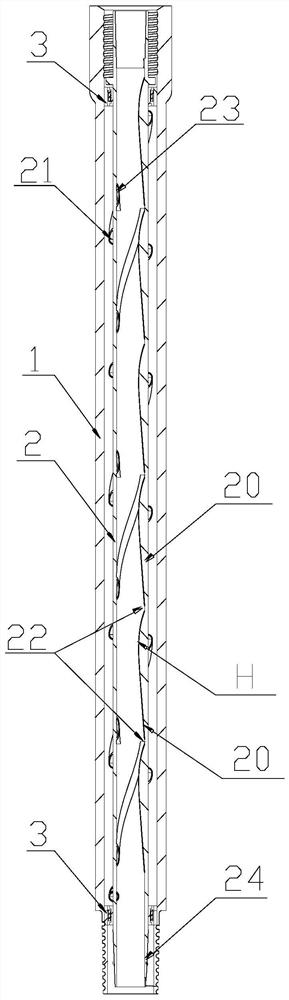

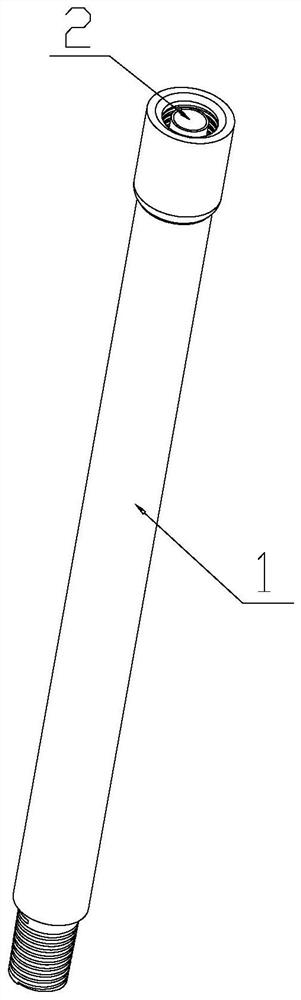

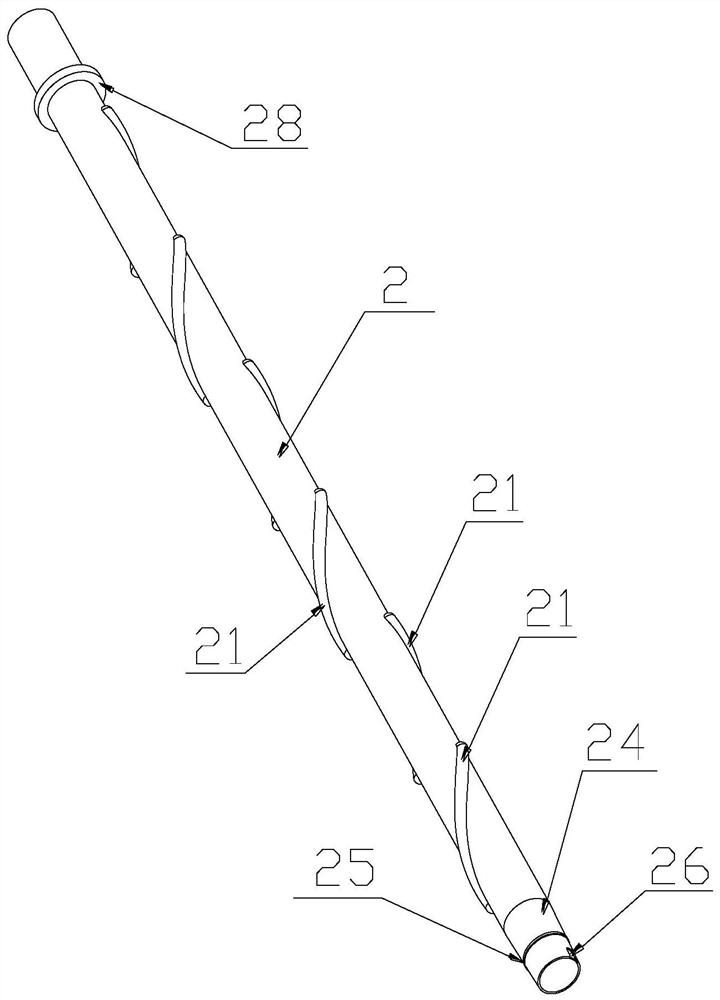

[0030] refer to Figure 1 to Figure 8 The shown oil pipe suitable for foam drainage and gas production in highly deviated wells mainly includes an outer cylinder 1 and an inner cylinder 2 both of which are hollow tubular structures. Similar to the structure of the ordinary oil pipe, the lower end is a male buckle, and the upper end is a corresponding female buckle. In this embodiment, the inner cylinder 2 is fixed in the outer cylinder 1 through the tapered roller bearing 3. Tapered roller bearings 3 are fixedly sleeved at the upper and lower ends near the ends, and the outer ring of the tapered roller bearing 3 is welded on the inner wall of the outer cylinder 1, which not only realizes the coaxial arrangement of the inner and outer cylinders, but also enables the The inner cylinder 2 can rotate horizontally relative to the outer cylinder 1 without ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com