A kind of mixing device for preparing amino silicone oil emulsion capable of proportioning

A technology of amino silicone oil and mixing device, which is applied to mixers, mixers, mixer accessories and other directions with rotary mixing devices, can solve the problems of inconvenient ratio control, uneven and incomplete mixing of raw materials, etc., and achieve uniform and thorough mixing. , Reduce the waste of raw materials, and ensure the effect of thoroughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

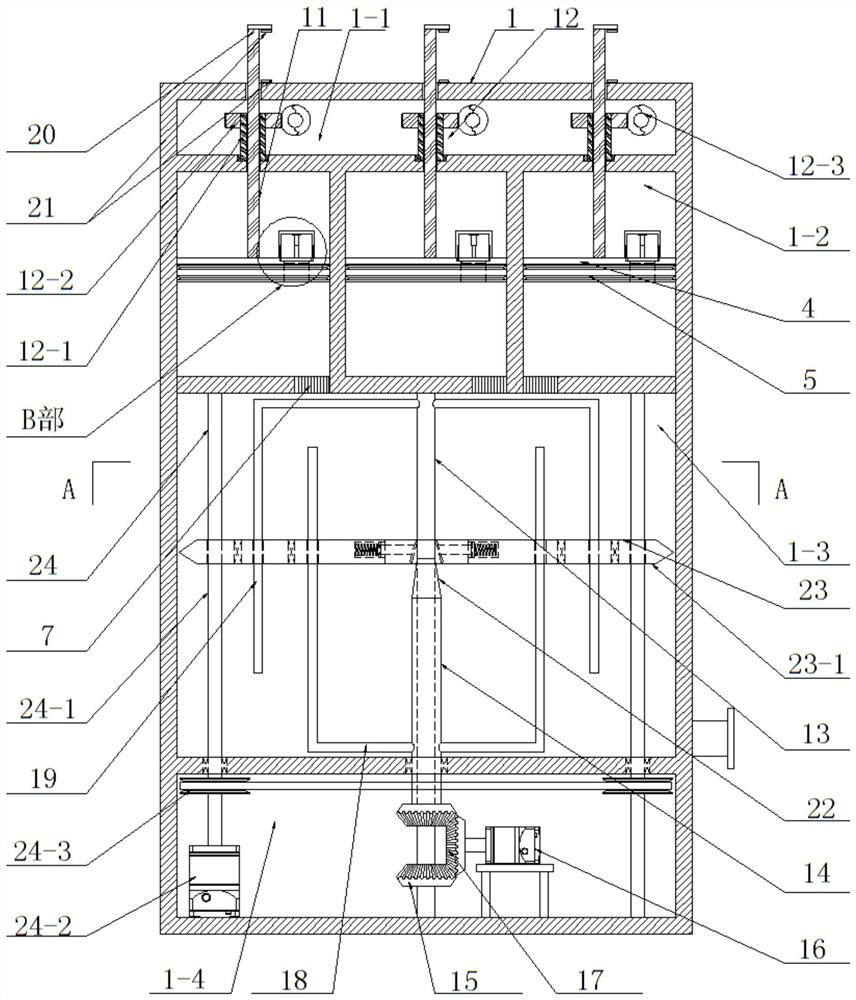

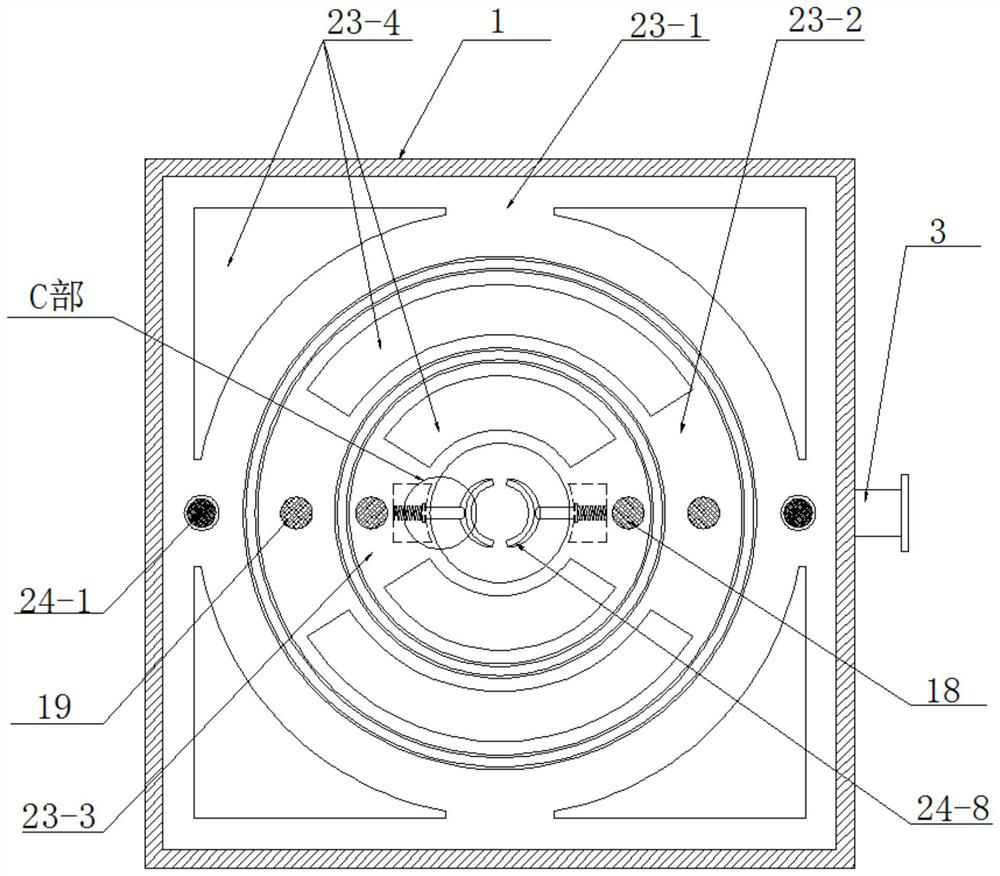

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

[0049] see as Figure 1-Figure 5 As shown, the technical solution adopted in this specific embodiment is: it includes a box body 1, a liquid inlet pipe 2 and a liquid outlet pipe 3; the inside of the box body 1 is sequentially divided into No. Two proportioning chambers 1-2, mixing chambers 1-3 and No. 2 regulating chambers 1-4 are arranged side by side; the front side walls of the three proportioning chambers 1-2 are all fixedly penetrated and welded with a liquid inlet pipe 2 for mixing The right side wall of the chamber 1-3 is fixed with a liquid outlet pipe 3 through welding;

[0050] It also contains:

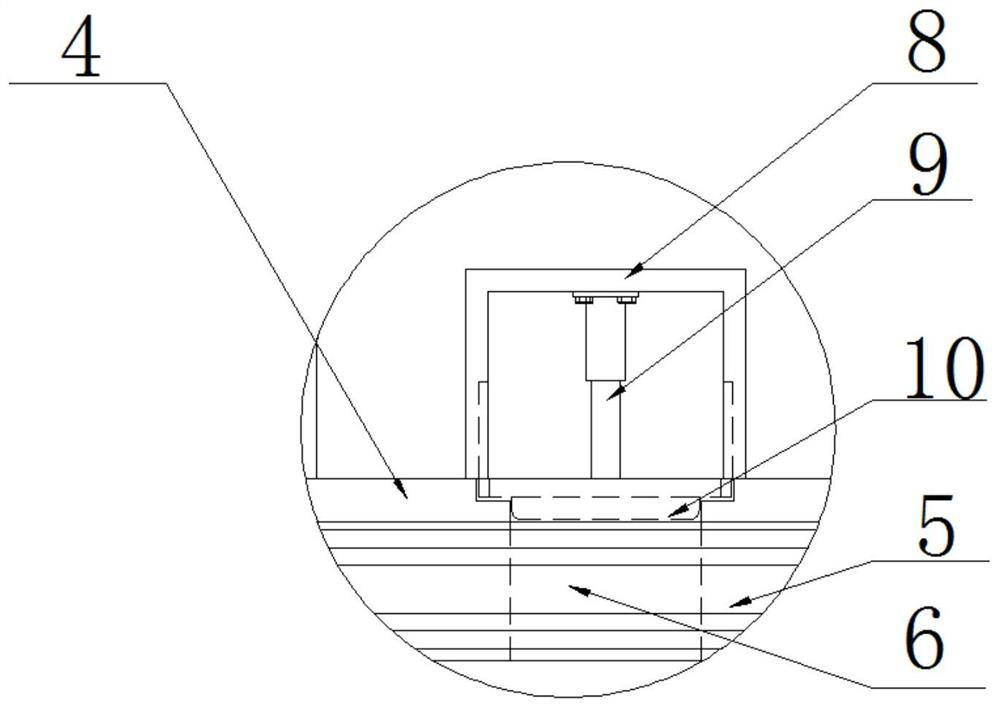

[0051] There are three regulating plates 4, and there are three regulating plates 4, which are respectively arranged inside the three proportioning chambers 1-2;

[0052] Piston 5, described piston 5 is three, and is fixedly arranged on the bottom surface of thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com