Machining auxiliary equipment suitable for petroleum pipes with different sizes

A technology for oil pipelines and auxiliary equipment, which is applied to metal processing equipment, metal processing machinery parts, manufacturing tools, etc., and can solve problems such as easy shaking of pipeline elbows, inability to meet the clamping requirements of pipeline elbows, and unstable fixation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

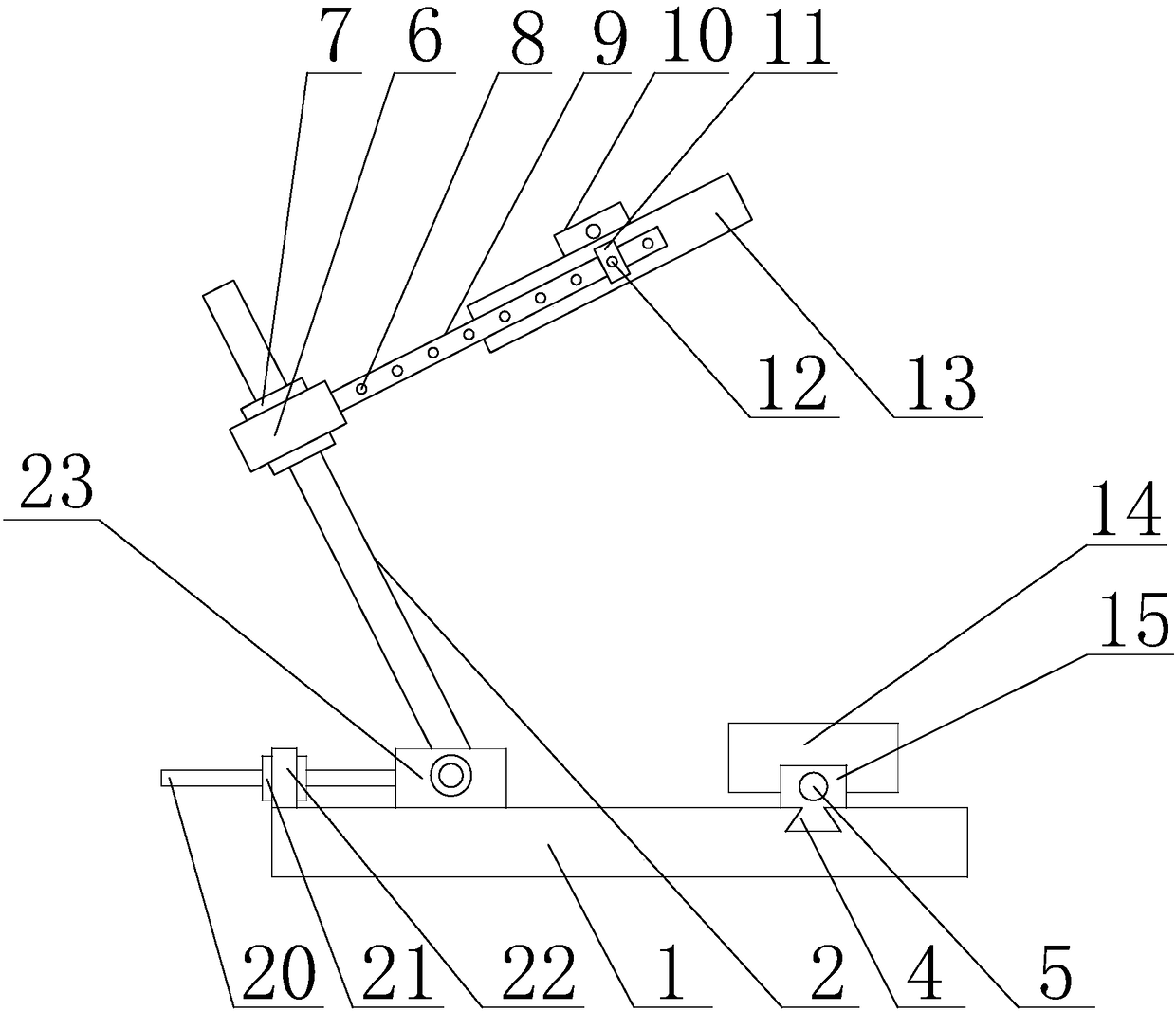

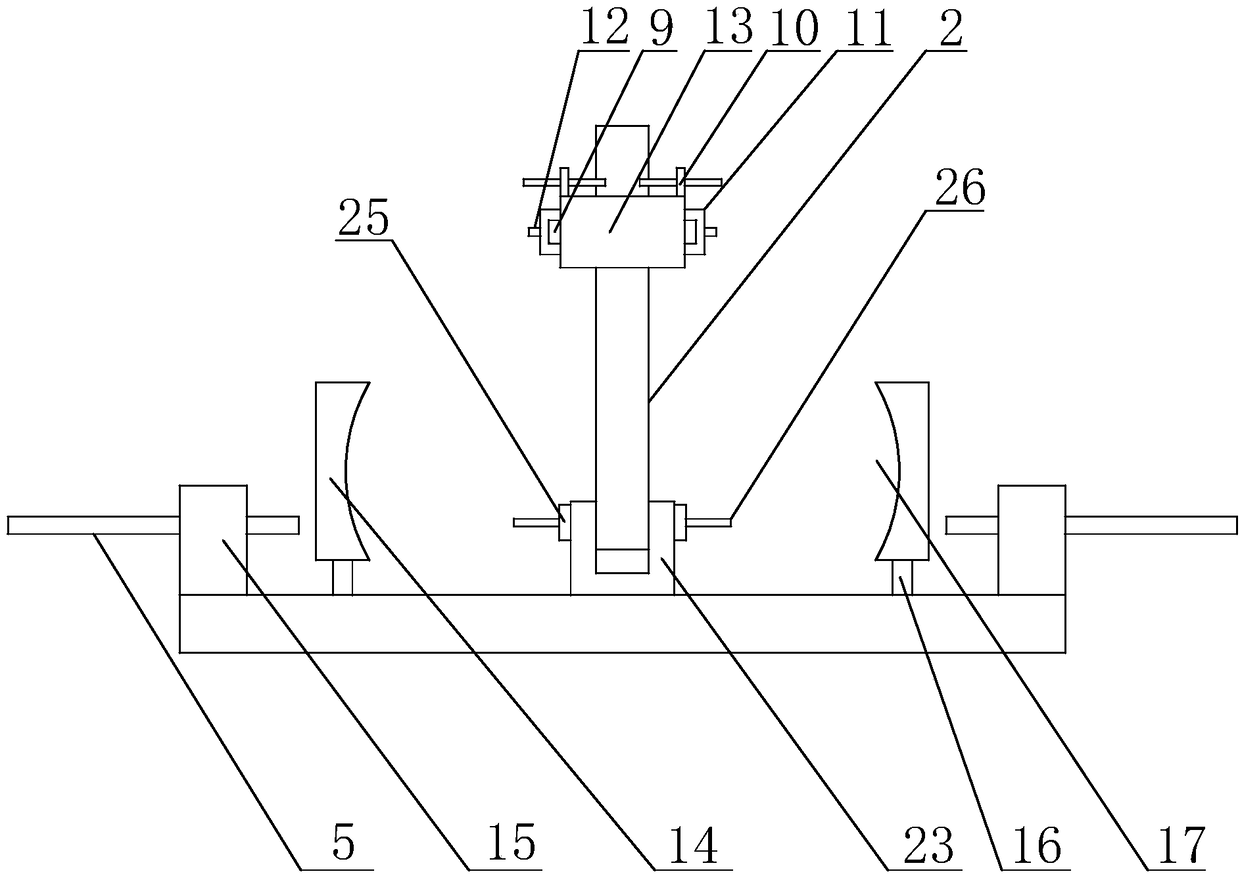

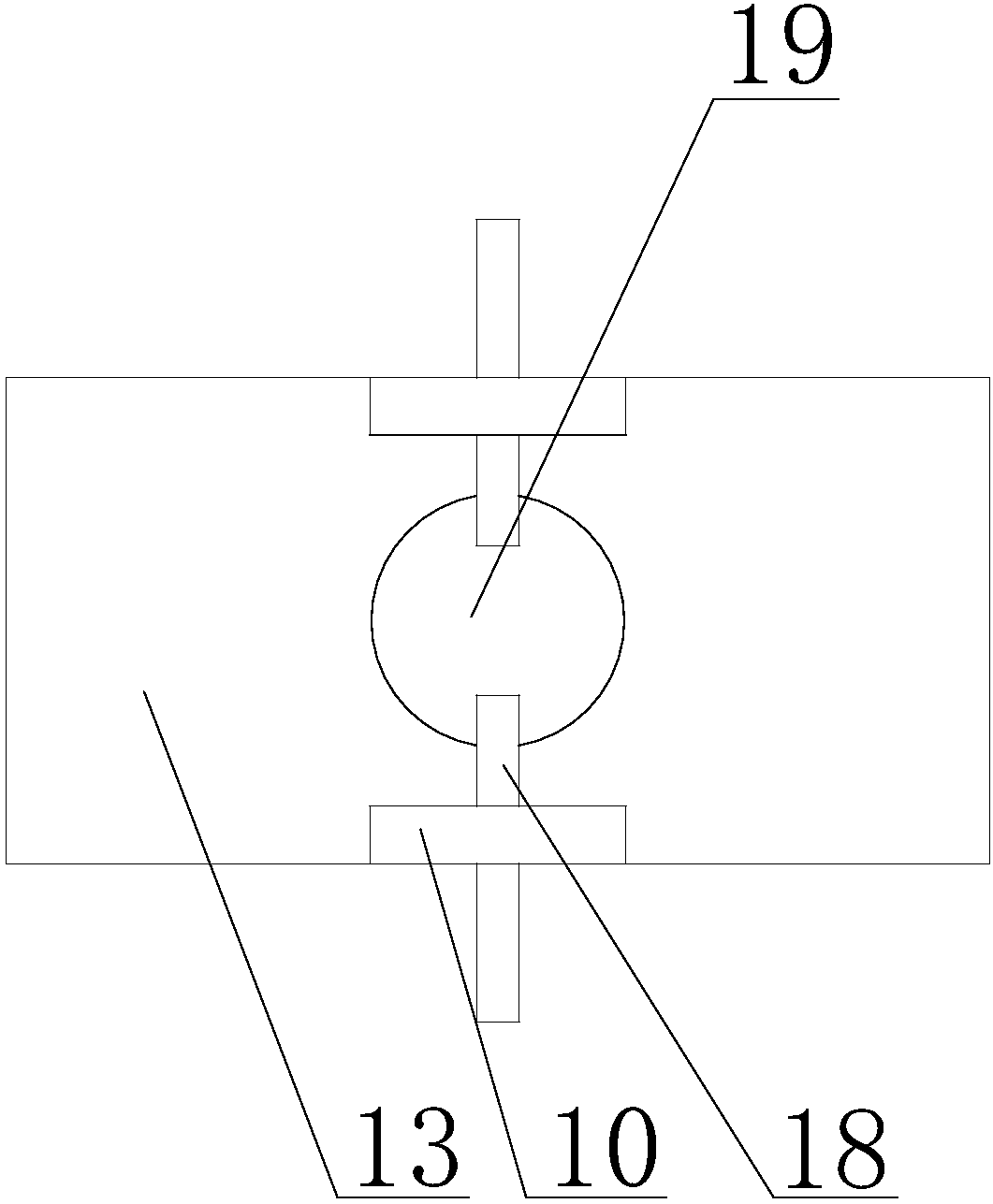

[0030] Such as Figure 1 to Figure 4As shown, the present invention is applicable to oil pipeline processing auxiliary equipment of different sizes, including a base 1, the base 1 is a rectangular structure, the top of the base 1 is provided with a first chute 4, and the first chute 4 is located in the center of the base 1 position, the first sliding block 16 is provided with the first sliding block 16 matching the first sliding slot in the first sliding slot 4, the first sliding block 16 can slide in the first sliding slot 4, and the top of the first sliding block 16 is also provided There is a clamping plate 14 for clamping the oil pipeline elbow. When the first slider 16 moves in the first chute 4, the clamping plate 14 can move together with the first slider 16 to change the two clamping positions. The distance between the plates 14 meets the clamping of elbows with different diameters. The clamping surfaces of the clamping plates 14 are provided with arc-shaped grooves 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com