False tooth polishing machine

A technique for polishing machines and dentures, which is applied in the field of denture polishing machines, and can solve problems such as poor precision, damaged dentures, and uneven manual polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

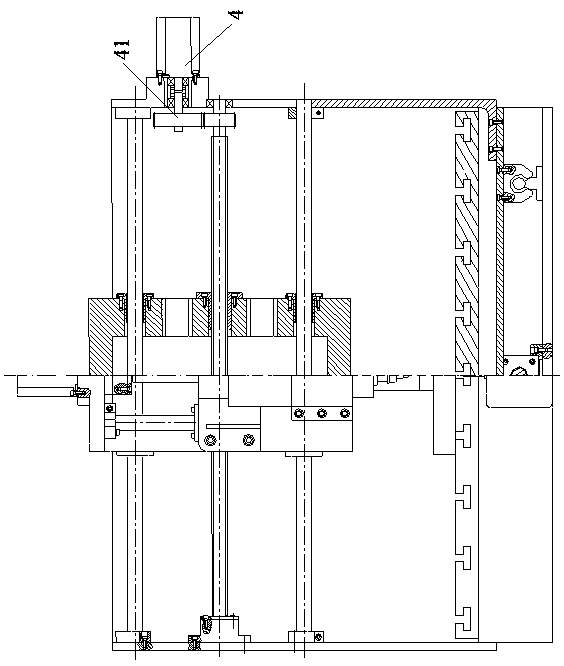

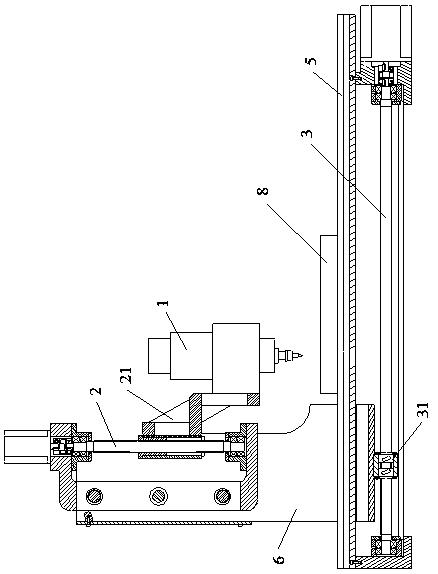

[0021] See Figure 1-8 , a kind of denture polishing machine, it comprises: vertical feeding mechanism 2, lateral feeding mechanism 3, longitudinal feeding mechanism 4, workbench 5, fixture 8;

[0022] Vertical feeding mechanism 2, which includes: servo motor, shaft coupling, bearing, lead screw, screw nut, screw nut seat, bent plate 21 connected with the screw nut seat, bent plate 21 is connected with polishing head 1; The feeding mechanism 2 is fixed on the support 6, and the lower end of the support 6 is connected with the transverse feed mechanism 3;

[0023] The transverse feed mechanism 3 includes: a servo motor, a shaft coupling, a bearing, and a screw nut clearance elimination structure 31; the screw nut clearance elimination structure 31 includes; a lead screw 311, a left Side outer ring gear 312, left inner ring gear 313, screw female seat 314, screw nut 315, right inner ring gear 316, right outer ring gear 317, left outer ring gear 312 meshes with left inner ring g...

Embodiment 2

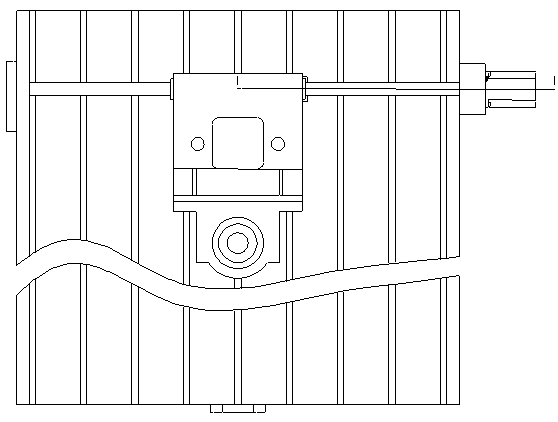

[0027] Preferably, in order to further improve the accuracy of the vertical feed mechanism 2, the lateral feed mechanism 3, and the longitudinal feed mechanism 4, the screw nut gap elimination structure 31 is adopted in these three feed mechanisms, and the tooth side gap elimination active The gear 41 and the driven gear meshed with it can realize the low-speed, constant-speed and high-speed feed motion of the feed mechanism by adjusting the transmission ratio of the active gear 41 and the driven gear meshed with it to eliminate backlash.

[0028] When assembling and adjusting, the arc-shaped hooks at both ends of the tension spring 416 are respectively hung on the middle round holes of the flat heads of the long screw 415 and the short screw 417 to ensure that after the gear clearance mechanism is installed, the thin-toothed gear 411 on the right 1. The tooth groove of the thin-toothed gear 412 on the left side at the same position, the tooth profile curved surface of each gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com