Full electromagnetic suspension type magnetic control rotor system

An electromagnetic levitation and rotor technology, applied in the direction of rotorcraft, aircraft control, aircraft parts, etc., can solve the problems of increased flight resistance of the control mechanism, reduced lift efficiency, complex and cumbersome reduction gear mechanism, etc. Friction, simple and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The principles and features of the present invention will be described below in conjunction with the accompanying drawings.

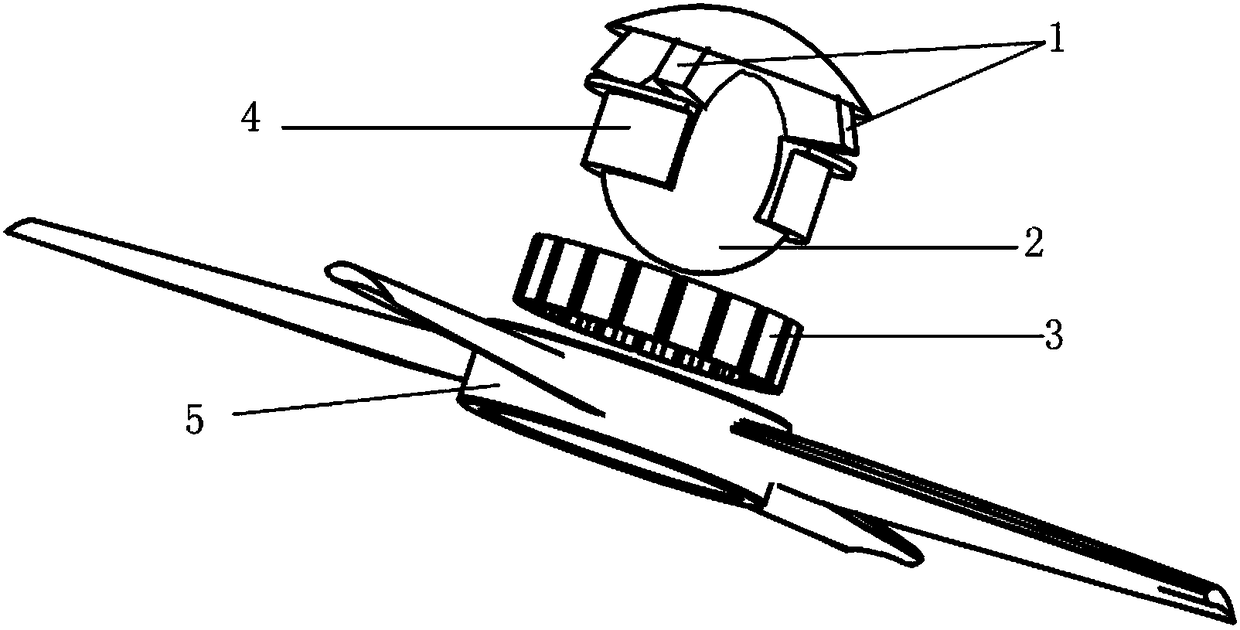

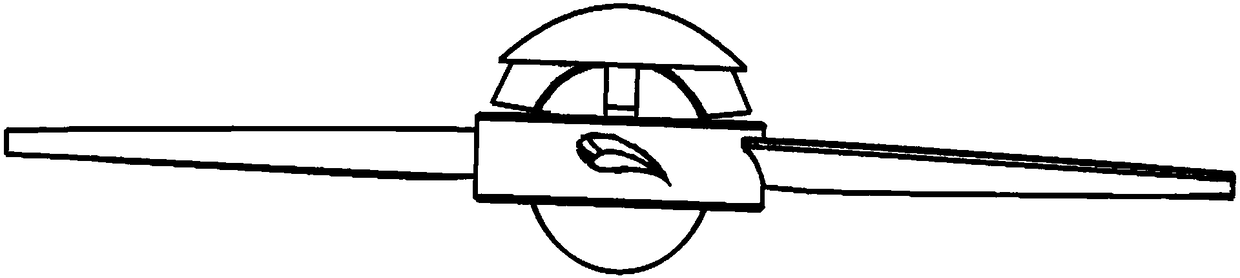

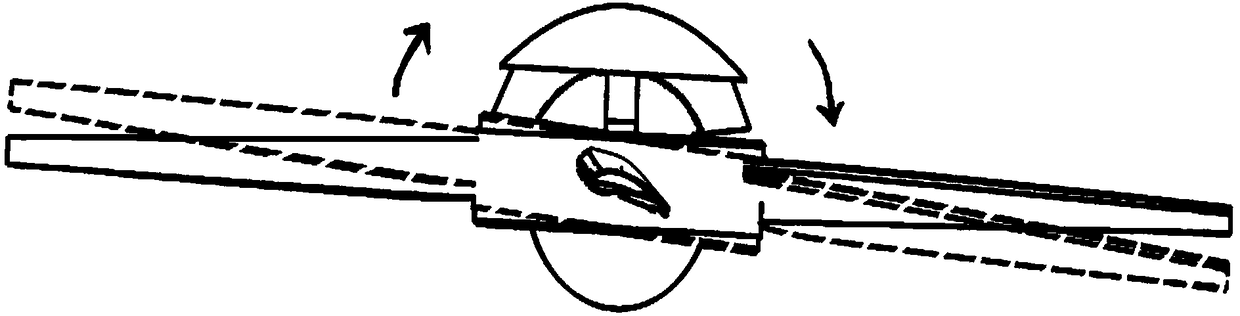

[0012] Full electromagnetic levitation magnetically controlled rotor system, including variable magnetic controller 1, rotor ball head 2, stator magnetic coil 3, inner curved stator 4 and rotor rotor fusion body 5; stator magnetic coil 3 is fixed on the inner curved stator 4 Outer ring, the rotor rotor fusion body 5 is set on the outer ring of the stator magnetic coil 3; the variable magnetic controller 1 is installed on the top of the rotor ball head 2, and the inside of the rotor ball head 2 is provided with a control system for controlling the variable magnetic controller 1 magnetic change; the inner curved ring-shaped stator 4 is sleeved on the rotor ball head 2, and the inner curved ring-shaped stator 4 and the rotor ball head 2 form an effective bonding surface, which can rotate around the rotor ball head 2, while the inner curved ring-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com