Super-low-temperature-resistant weather-resistant low-smoke halogen-free flame-retarding PC material and preparation method thereof

A low-temperature and weather-resistant technology, which is applied in the field of ultra-low temperature and weather-resistant low-smoke halogen-free flame retardant PC materials and their preparation, can solve the problems of reduced impact resistance, insufficiently dense stacking, and pulverization, and achieves excellent light and moisture resistance. , The effect of excellent processing fluidity and balanced weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

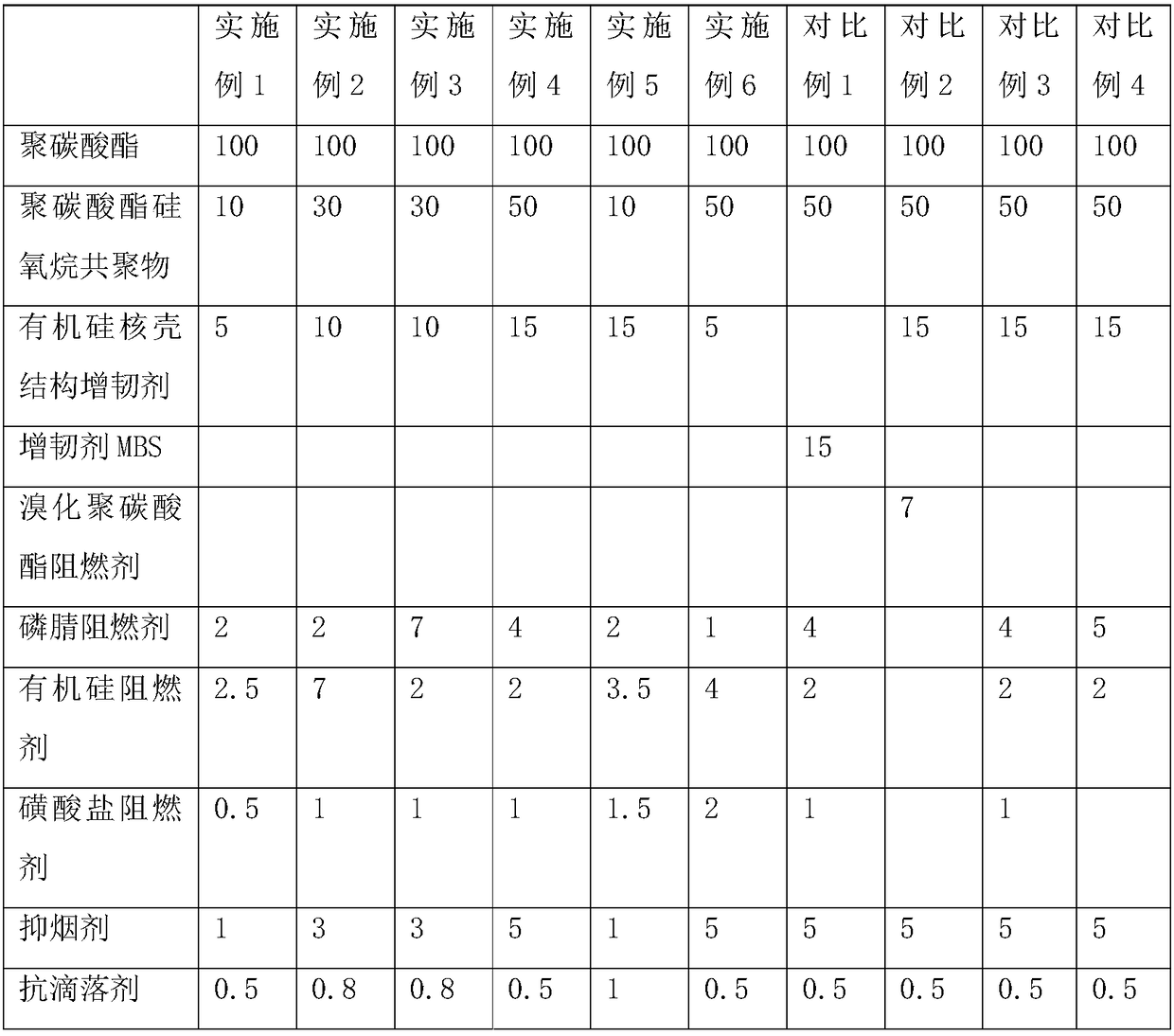

Embodiment 1

[0033] This example provides a super-low-temperature-resistant, weather-resistant, low-smoke, halogen-free, and flame-retardant PC material and its preparation method. The ingredients are prepared according to the following parts by weight: 100 parts of polycarbonate PC; 10 parts of polycarbonate siloxane copolymer; 5 parts of silicone core-shell structure toughening agent; 2 parts of phosphazene flame retardant; 2.5 parts of silicone flame retardant; 0.5 part of sulfonate flame retardant; 1 part of smoke suppressant; 0.5 parts of stabilizer; 1.5 parts of anti-hydrolysis agent; 1 part of flow modifier.

[0034] The above-mentioned raw materials are put into a high mixer and mixed evenly to obtain a premixed material. Then the premixed material is added into a twin-screw extruder, melted and extruded to granulate, the screw temperature of each section of the twin-screw extruder is controlled between 250-270°C, and the screw speed is 500 rpm. The obtained particles were dried a...

Embodiment 2

[0036] This example provides a super-low-temperature-resistant, weather-resistant, low-smoke, halogen-free, and flame-retardant PC material and its preparation method. The ingredients are prepared according to the following parts by weight: 100 parts of polycarbonate PC; 30 parts of polycarbonate siloxane copolymer; 10 parts of silicone core-shell structure toughening agent; 2 parts of phosphazene flame retardant; 7 parts of silicone flame retardant; 1 part of sulfonate flame retardant; 3 parts of smoke suppressant; 1.5 parts of stabilizer; 1 part of anti-hydrolysis agent; 2 parts of flow modifier.

[0037] The above-mentioned raw materials are put into a high mixer and mixed evenly to obtain a premixed material. Then the premixed material is added into a twin-screw extruder, melted and extruded to granulate, the screw temperature of each section of the twin-screw extruder is controlled between 250-270°C, and the screw speed is 500 rpm. The obtained particles were dried at 10...

Embodiment 3

[0039] This example provides a super-low-temperature-resistant, weather-resistant, low-smoke, halogen-free, and flame-retardant PC material and its preparation method. The ingredients are prepared according to the following parts by weight: 100 parts of polycarbonate PC; 30 parts of polycarbonate siloxane copolymer; 10 parts of silicone core-shell structure toughening agent; 7 parts of phosphazene flame retardant; 2 parts of silicone flame retardant; 1 part of sulfonate flame retardant; 3 parts of smoke suppressant; 1 part of stabilizer; 1.5 parts of anti-hydrolysis agent; 2 parts of flow modifier.

[0040] The above-mentioned raw materials are put into a high mixer and mixed evenly to obtain a premixed material. Then the premixed material is added into a twin-screw extruder, melted and extruded to granulate, the screw temperature of each section of the twin-screw extruder is controlled between 250-270°C, and the screw speed is 500 rpm. The obtained particles were dried at 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notch shock | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com