Low-temperature dispersion yellow dye composition and preparation method thereof

A dye composition and disperse yellow technology, applied in the direction of organic dyes, etc., can solve problems such as no breakthrough results, and achieve the effect of improving level dyeing performance, high synchronization, and good lifting power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

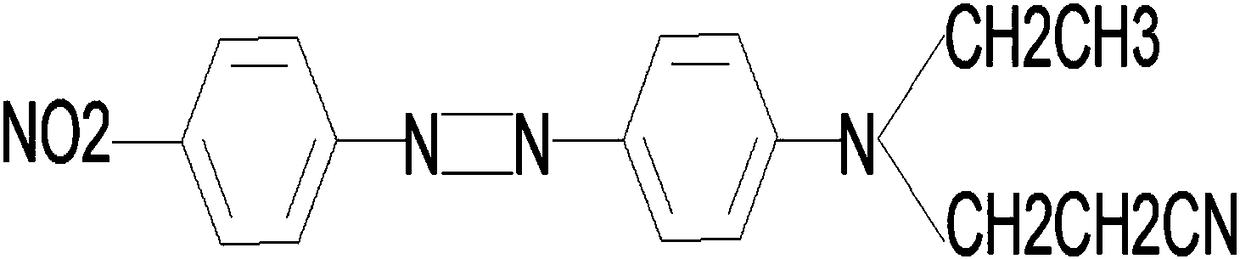

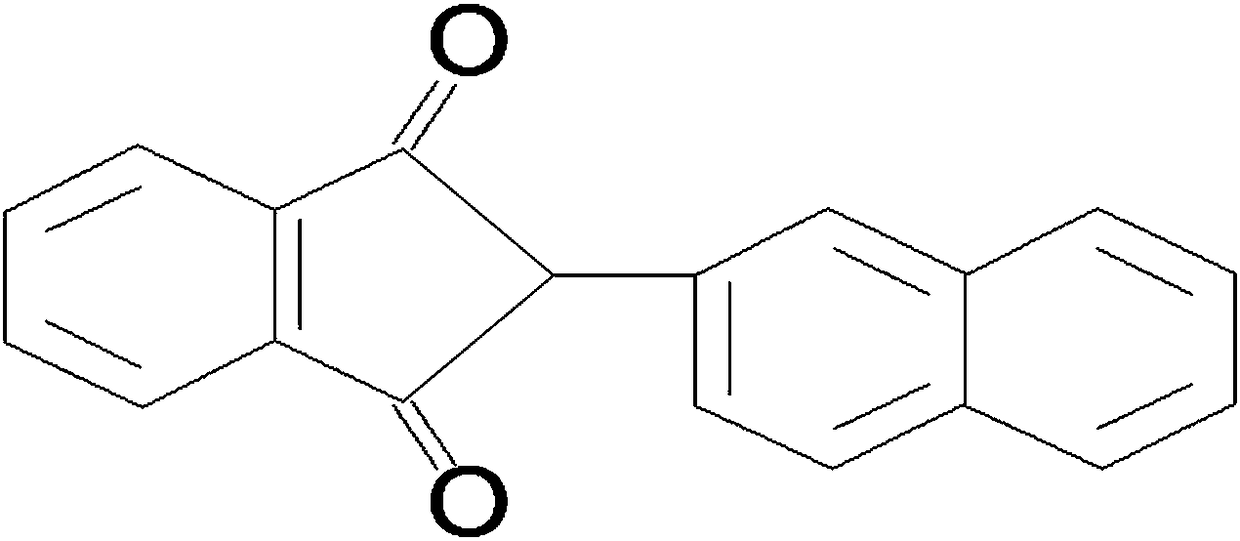

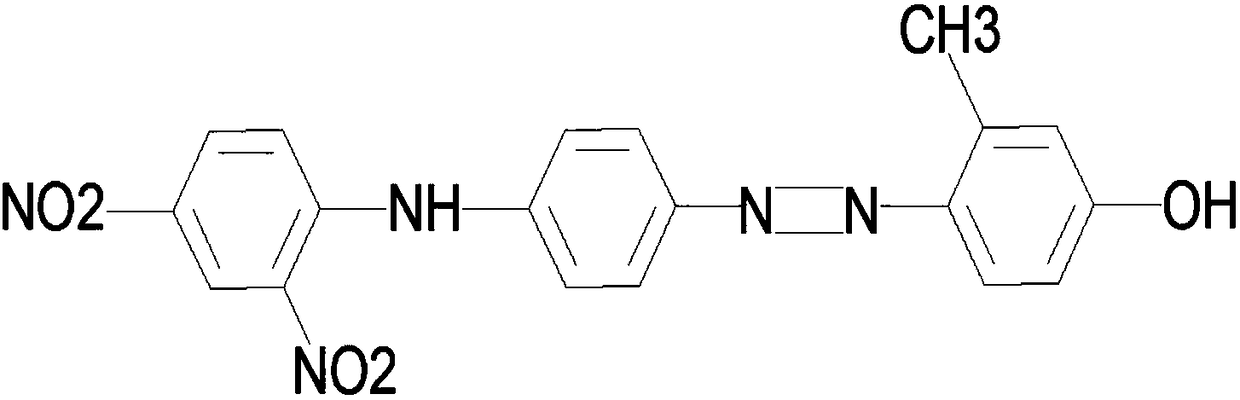

[0025] A low-temperature disperse yellow dye composition, consisting of the following raw materials in mass percent:

[0026] The monomer A is 55% by mass, the monomer B is 12% by mass, the monomer C is 10% by mass, and the balance is additives.

[0027] The preparation method of the above-mentioned low-temperature disperse yellow dye composition comprises the following steps: weighing each monomer and auxiliary agent in proportion, adding them to a dispersing kettle, adding water and beating to obtain a slurry, transferring the slurry to a liquid fine grinder for pulverization, It is then transferred to a sand mill for grinding for 40 hours. After grinding, it is stirred and ultrasonicated for 5 minutes, and then sent to a microwave drying room for drying. At the same time, it is sprayed with a dust-proof agent to obtain a finished product.

Embodiment 2

[0029] A low-temperature disperse yellow dye composition, consisting of the following raw materials in mass percent:

[0030] The monomer A is 45% by mass, the monomer B is 25% by mass, the monomer C is 5% by mass, and the balance is additives.

[0031] The preparation method of the above-mentioned low-temperature disperse yellow dye composition comprises the following steps: weighing each monomer and auxiliary agent in proportion, adding them to a dispersing kettle, adding water and beating to obtain a slurry, transferring the slurry to a liquid fine grinder for pulverization, It is then transferred to a sand mill for grinding for 50 hours. After grinding, it is stirred and ultrasonicated for 5 minutes, and then sent to a microwave drying room for drying. At the same time, it is sprayed with a dust-proof agent to obtain a finished product.

Embodiment 3

[0033] A low-temperature disperse yellow dye composition, consisting of the following raw materials in mass percent:

[0034] The monomer A is 40% by mass, the monomer B is 10% by mass, the monomer C is 4% by mass, and the balance is additives.

[0035] The preparation method of the above-mentioned low-temperature disperse yellow dye composition comprises the following steps: weighing each monomer and auxiliary agent in proportion, adding them to a dispersing kettle, adding water and beating to obtain a slurry, transferring the slurry to a liquid fine grinder for pulverization, It is then transferred to a sand mill for grinding for 50 hours. After grinding, it is stirred and ultrasonicated for 5 minutes, and then sent to a microwave drying room for drying. At the same time, it is sprayed with a dust-proof agent to obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com