Efficient central air conditioning unit liquid storage gas-liquid separator

A gas-liquid separator, central air-conditioning technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., to achieve the effect of improving efficiency and increasing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

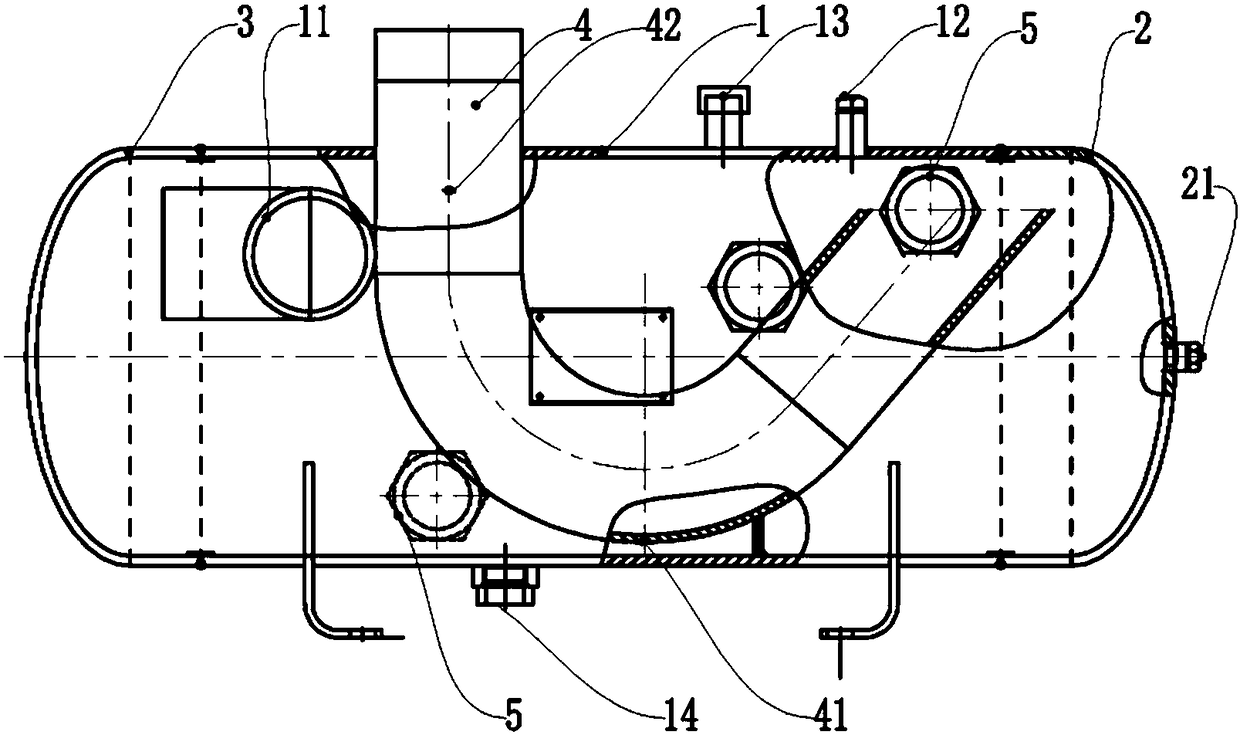

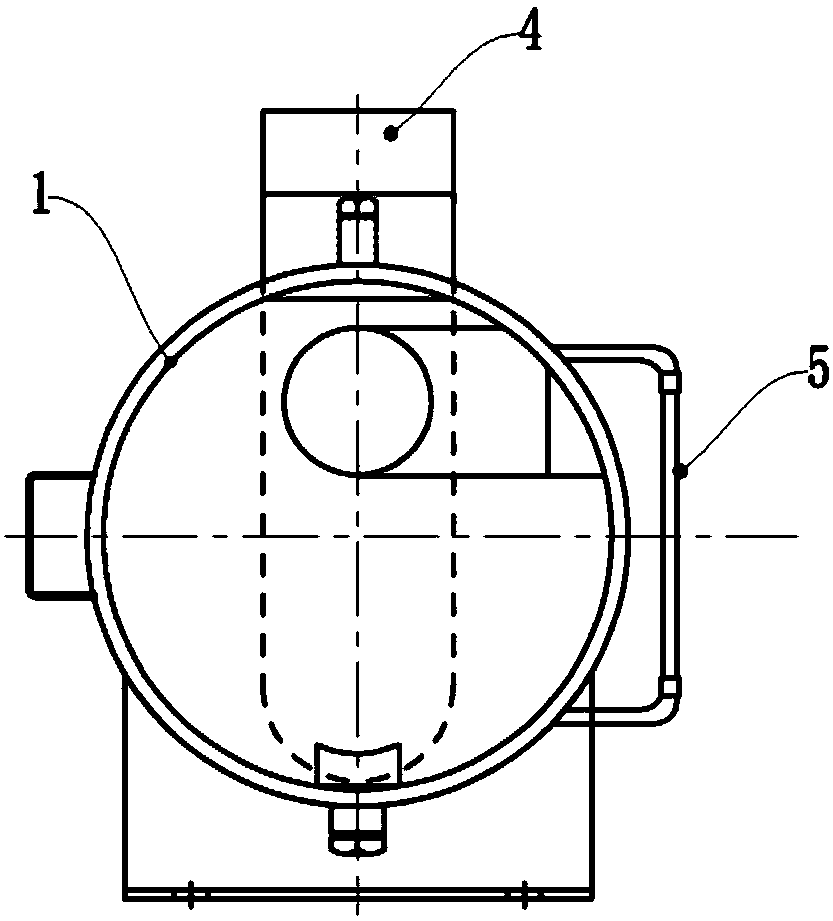

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

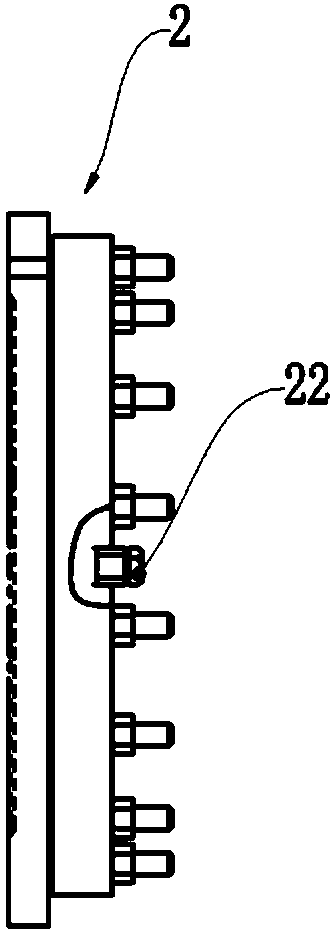

[0023] High-efficiency central air-conditioning unit liquid storage gas-liquid separator, including horizontal cylinder 1, front cover 2, rear cover 3, air outlet pipe 4 and sight glass 5;

[0024] The horizontal cylinder 1 is a circular iron cylinder placed horizontally, and the front cover 2 and the rear cover 3 are respectively blocked at the front end and the rear end of the horizontal cylinder 1 to form a sealed pressure vessel; The side of the half part is provided with a round hole, which is closer to the direction of the rear cover 3, and the inside of the round hole is connected with an inlet pipe 11 by welding; the inlet pipe 11 is provided with a 90° bend, so that The outlet of the inlet pipe 11 faces the direction of the rear cover 3 of the horizontal cylinder 1;

[0025] The inlet pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com