Refrigerating agent pipeline horizontal type gas-liquid separator in front of compressor

A gas-liquid separator and refrigerant tube technology, which is used in refrigeration and liquefaction, refrigerators, refrigeration components, etc., to achieve the effect of increasing distance and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

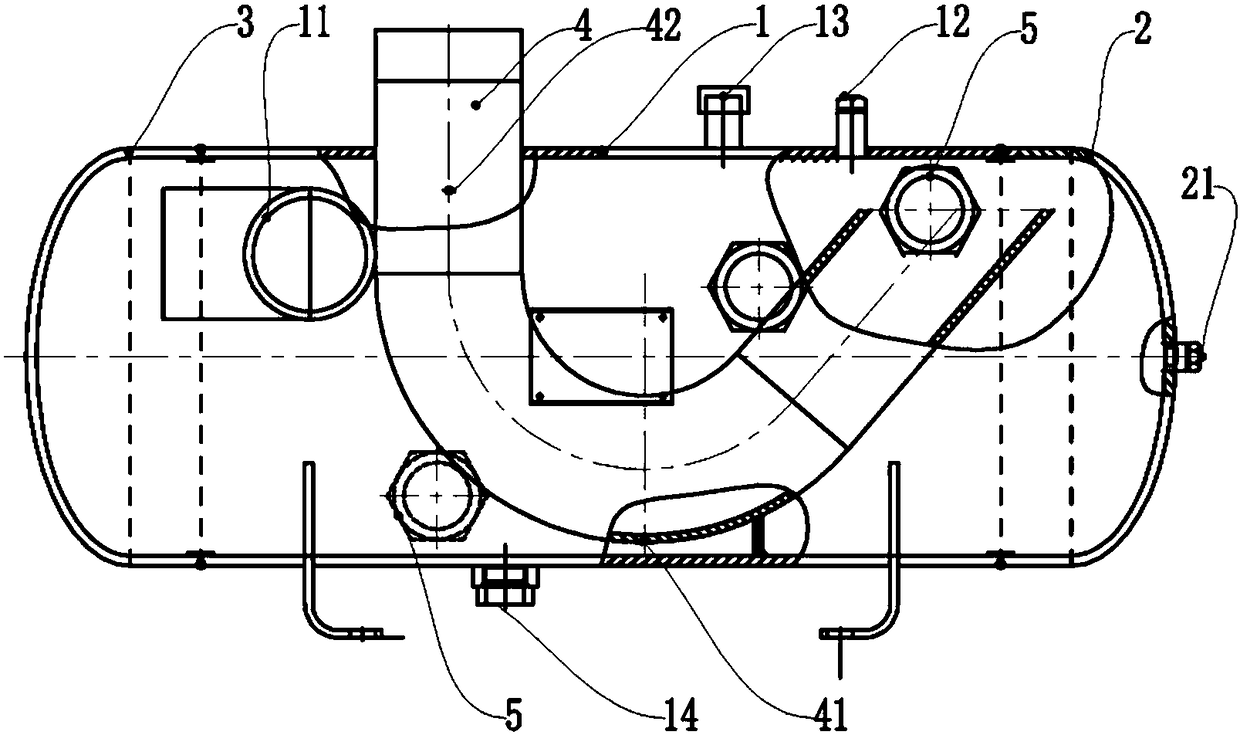

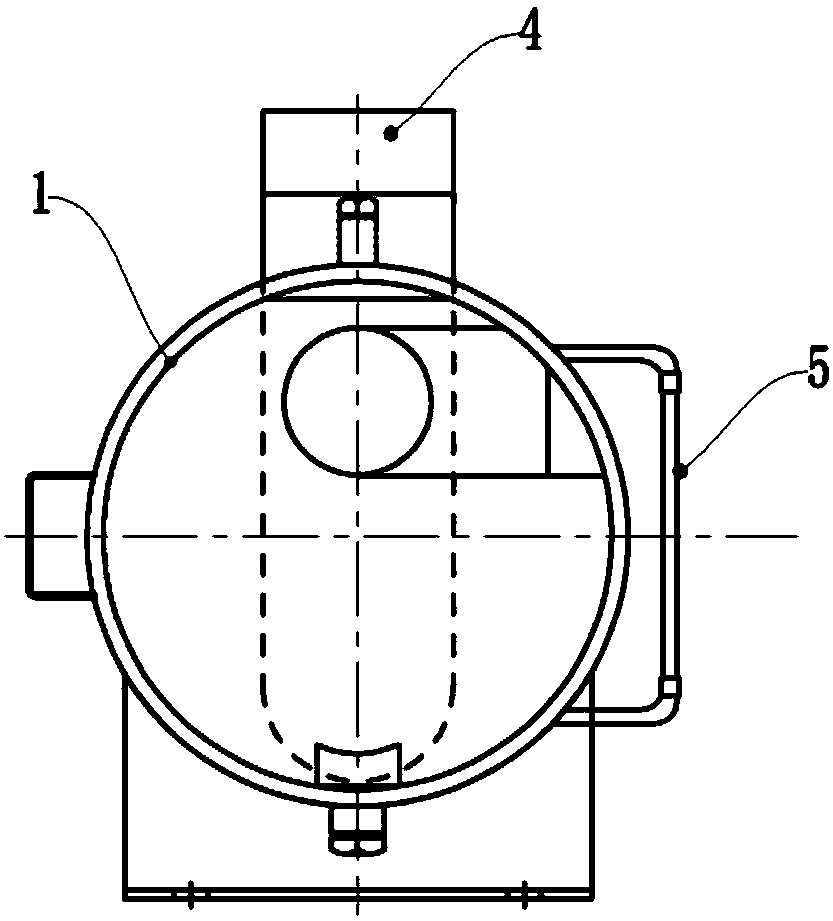

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

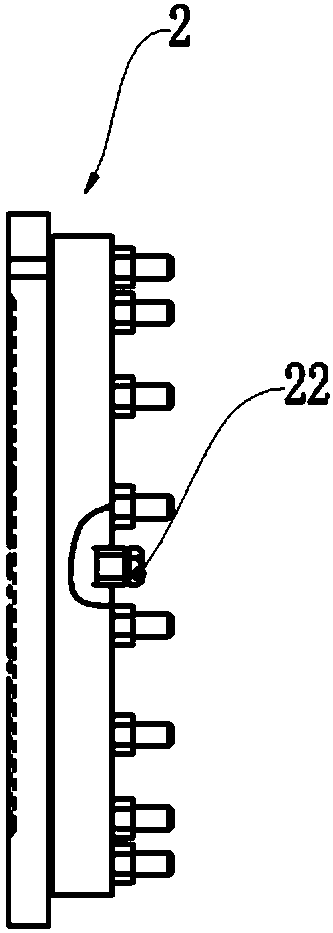

[0023] A horizontal gas-liquid separator for the refrigerant pipeline in front of the compressor, including a horizontal cylinder 1, a front cover 2, a rear cover 3, an air outlet pipe 4 and a sight glass 5;

[0024] The horizontal cylinder 1 is a circular iron cylinder placed horizontally, and the front cover 2 and the rear cover 3 are respectively blocked at the front end and the rear end of the horizontal cylinder 1 to form a sealed pressure vessel; the top of the horizontal cylinder 1 A round hole is provided, which is closer to the direction of the rear cover 3, and the inside of the round hole is connected with an inlet pipe 11 by welding, and the inlet pipe 11 is a straight pipe with an inclined cut, so that the The outlet of the inlet pipe 11 faces the direction of the rear cover 3;

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com