Device and method for monitoring impurity rate and breaking rate of grains in grain tank of combine harvester in real time

A combine harvester and real-time monitoring technology, which is applied in the direction of measuring devices, testing moving fluid/granular solids, and material analysis through optical means. Problems such as service life and unfavorable image acquisition can achieve the effect of improving equipment supply capacity, reducing shooting difficulty, and ensuring clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the purpose, technical solutions and advantages of the present invention, the invention will be further described below in conjunction with the accompanying drawings and specific examples, but the protection scope of the present invention is not limited thereto.

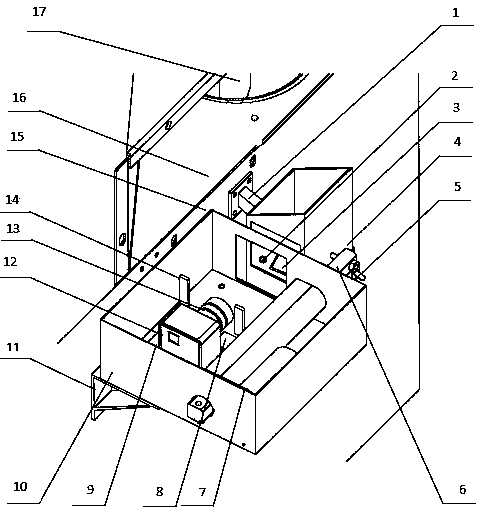

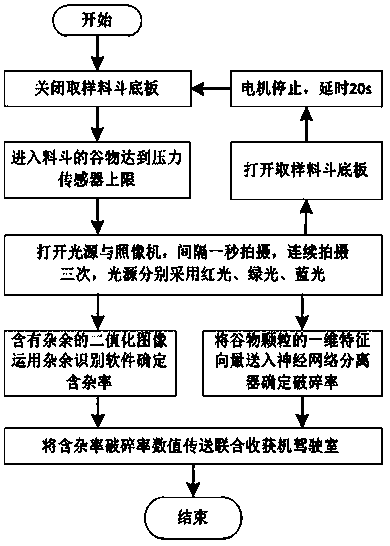

[0023] The real-time monitoring device for the grain impurity rate and broken rate of the combine harvester auger type grain output grain box described in the present embodiment comprises a grain auger 17, a grain box 15, a CCD camera 12, a lens 13, and a variable light source 14. Described variable light source 14 is positioned at described camera lens 13 both sides, is used for providing lighting during shooting; The grain tank grain inlet 16 place of described grain tank 15 is provided with sampling hopper 4, and the inner wall of described sampling hopper 4 is provided with pressure. Sensor 2, the bottom of the sampling hopper 4 is equipped with a movable bottom plate 3, the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com