Drawer type fiber distribution frame

A fiber optic distribution frame and drawer-type technology, which is applied in the field of distribution frame design, can solve problems such as narrow operating space, interruption of optical cables, and insufficient redundancy of optical cables, and achieve the effect of safe and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

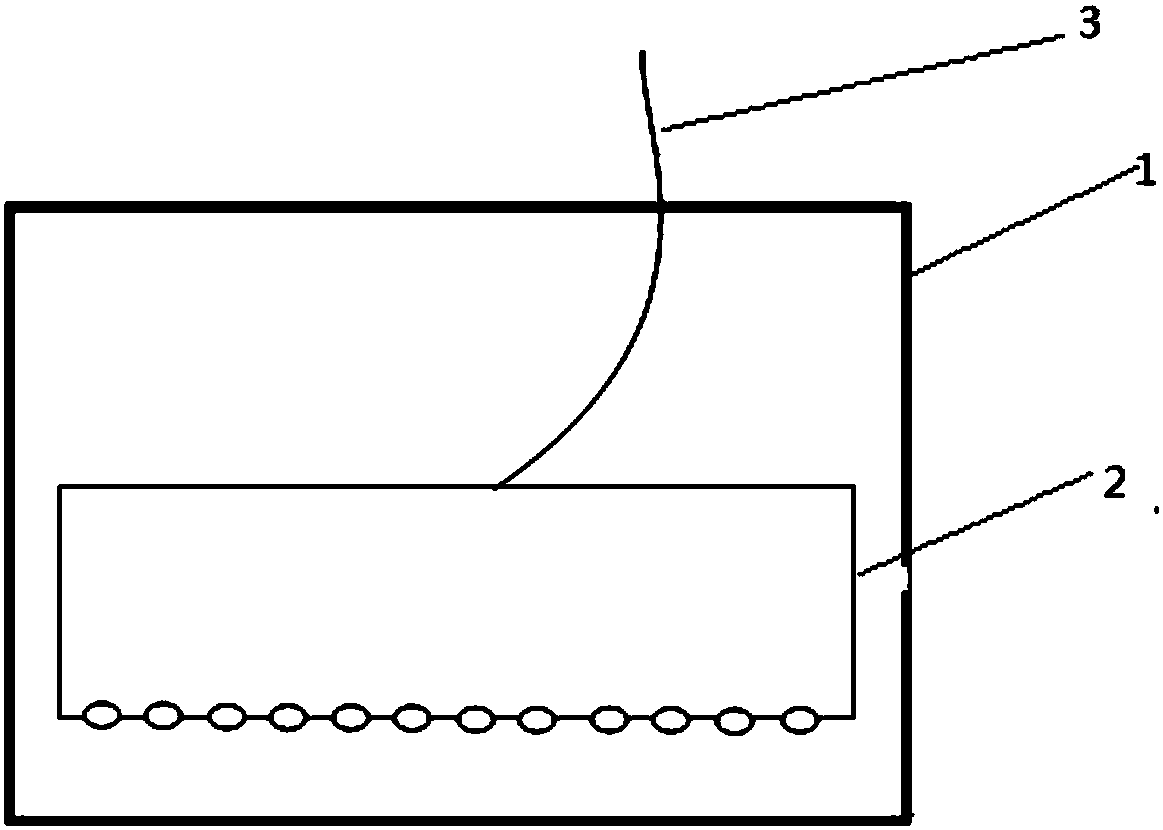

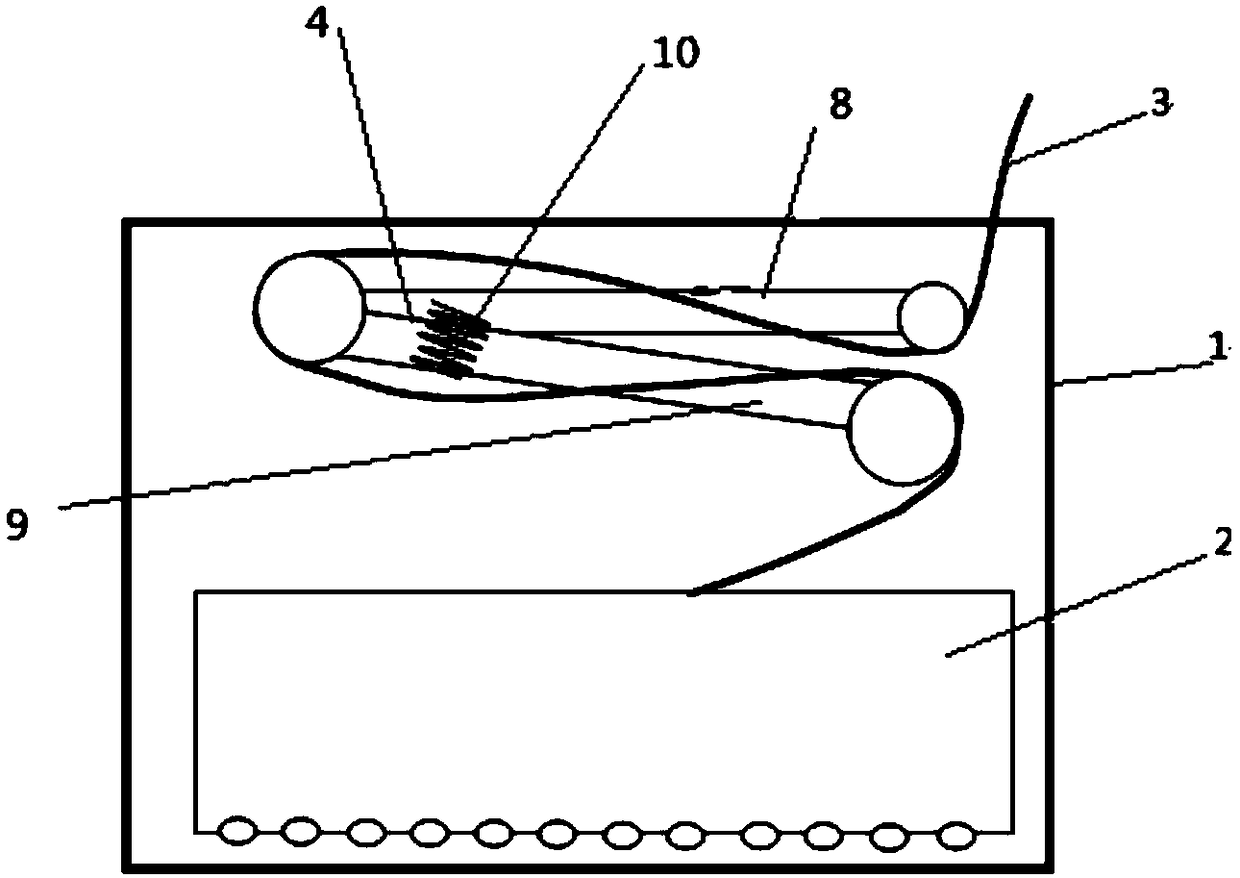

[0026] Drawer-type optical fiber distribution frame, in the existing drawer-type distribution frame such as figure 1 After making improvements such as figure 2 As shown, it includes a housing 1, a distribution box 2 and an optical fiber 3. The distribution box is arranged inside the housing 1, and the optical fiber 3 is arranged in the distribution box 2. The active connector of the margin, the optical fiber 3 is installed on the active connector 4, the optical fiber margin is the length of the optical fiber remaining outside the distribution box when the distribution box is pulled out or put in, and it can be avoided by changing the optical fiber margin When the optical fiber is pulled out because there is not enough margin, the optical fiber is broken.

Embodiment 2

[0028] combine 2 and image 3 , the biggest difference between the present invention and the traditional optical fiber distribution frame is the movable connector 4, the optical fiber 3 according to figure 2 Mounted on active connector 4.

[0029] The movable connector can automatically adjust the length of the optical fiber according to the position of the fiber tray, so that the fiber tray can be put in and out of the shell smoothly.

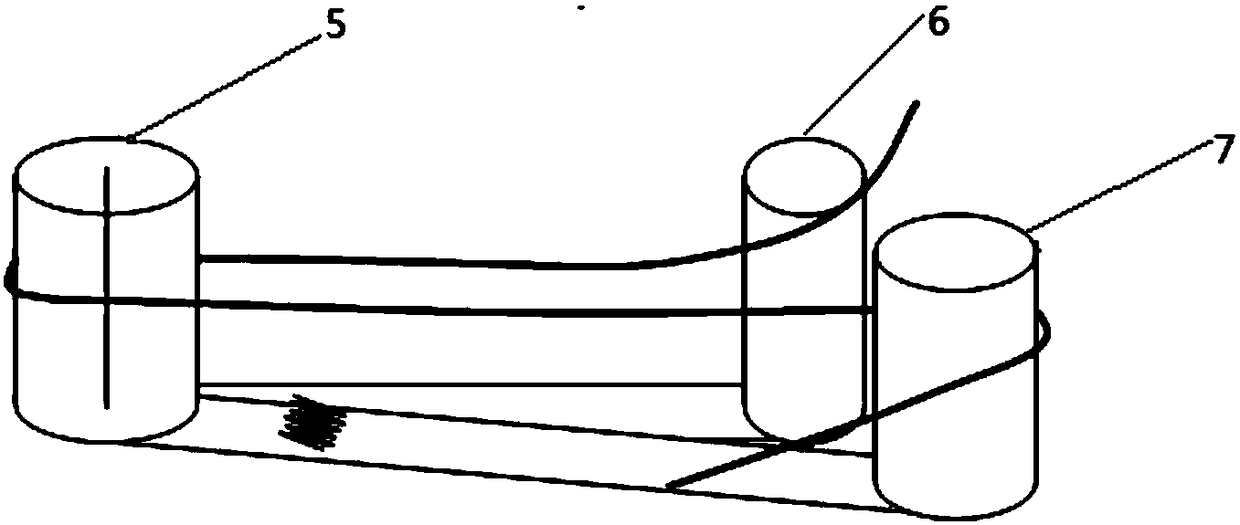

[0030] The movable connector is composed of cylinders 5, 6, 7, springs and connecting rods. The cylinders 5 and 6, and the cylinders 5 and 7 are connected by connecting rods. The cylinders 5 and 6 are fixed, and the cylinder 7 is movable. . Connecting rod 1 is between cylinder 5,6, connecting rod 2 is between cylinder 5,7, connects with spring between connecting rod 1,2. The middle of the cylinder 5 is fixed with screws, which can ensure that the cylinder 7 rotates around the cylinder 5, and the spring can automatically recover after the a...

Embodiment 3

[0034] Such as Figure 5 As shown, according to the actual situation, there may be multiple distribution boxes 2 in the housing 1. Designing a line card on the outside of the cylinder and putting different optical fibers into the line card can not only ensure clear and beautiful wiring, but also meet multiple requirements. The use of distribution boxes also ensures that there will be no knotting between different optical fibers.

[0035] The line card is designed on the outside of the cylinder, which can meet the use of multiple distribution boxes, and also ensures that there will be no knotting between different optical fibers

[0036] The line card includes a plurality of protrusions 11, grooves 12 are formed between the protrusions, and optical fibers 3 are placed in the grooves

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com