An anti-static mask

An anti-static, photomask technology, applied in optics, originals for opto-mechanical processing, instruments, etc., to avoid damage, improve anti-static damage capability, and reduce the risk of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

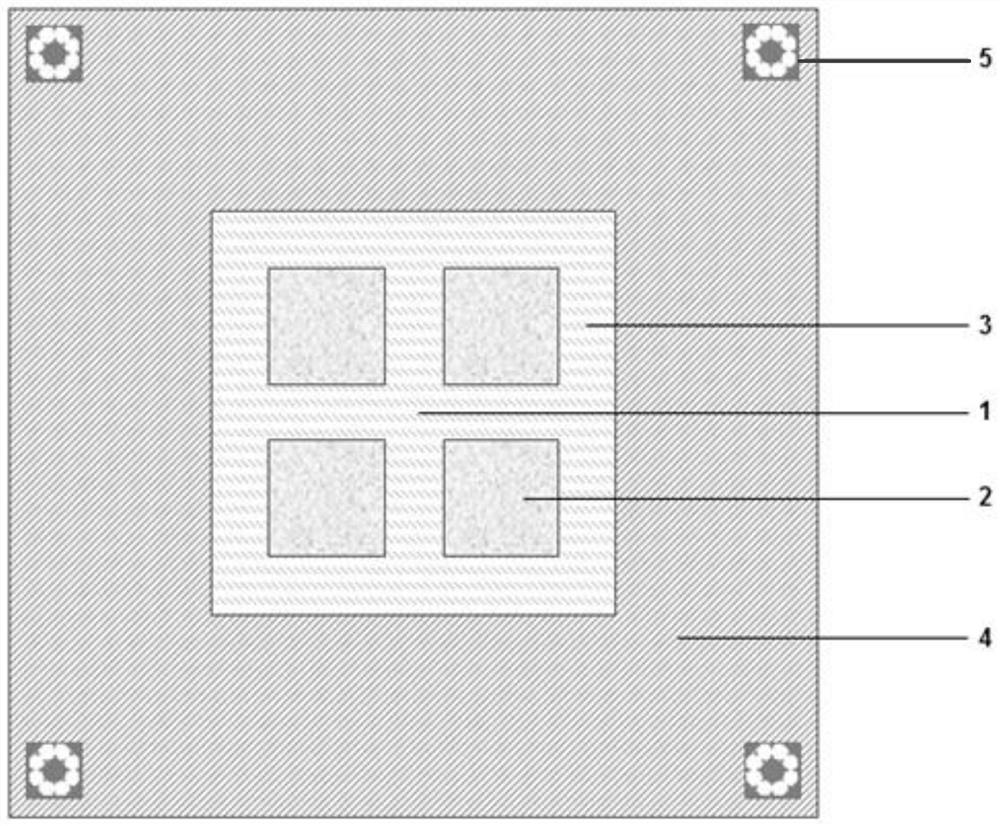

[0041] In order to solve the technical problems existing at present, the present invention provides an antistatic photomask, which mainly includes:

[0042] transparent substrate;

[0043] A photomask pattern arranged on the transparent substrate;

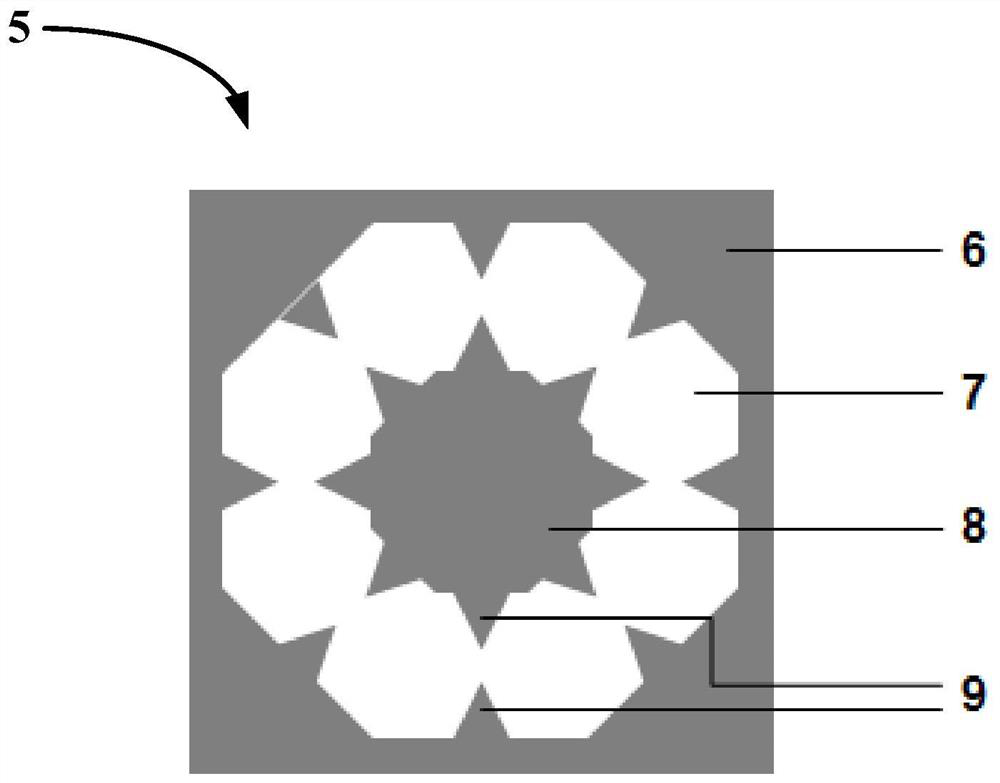

[0044] a conductive light-shielding layer, disposed on the transparent substrate at the periphery of the mask pattern, and spaced apart from the mask pattern;

[0045] The discharge structure is arranged on the conductive light-shielding layer.

[0046] The antistatic photomask of the present invention is provided with a discharge structure on the conductive light-shielding layer on the periphery of the photomask pattern, which can guide a large amount of static charge accumulated on the large-area continuous conductive light-shielding layer outside the photomask pattern, and place it away from the photomask pattern area. Discharge is carried out, thereby avoiding the damaging effect of electrostatic charge directly discharging o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com