Constant-pressure wind supply electric control system of air blower and electric control method of constant-pressure wind supply electric control system

An electronic control system and blower technology, applied in the control/regulation system, fluid pressure control, non-electric variable control, etc., can solve the problems that the roots blower cannot supply air at constant pressure, and the main motor of the blower is burned out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

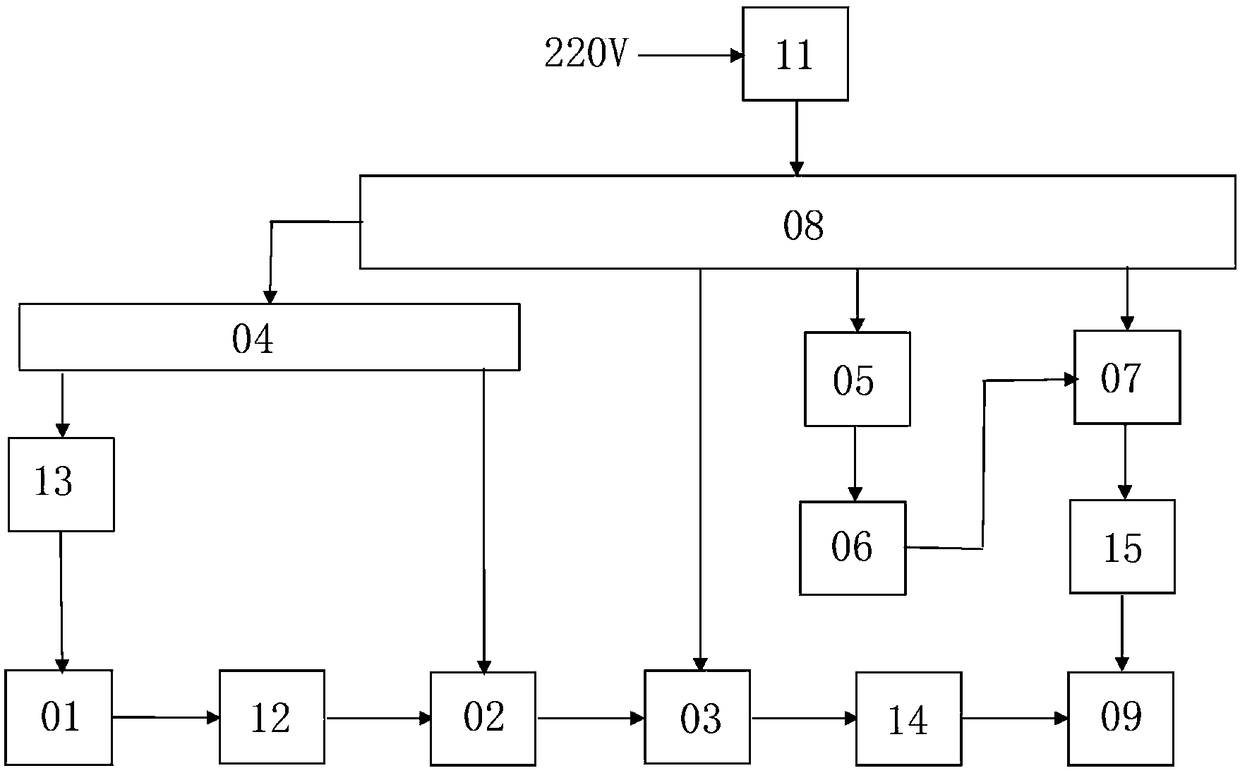

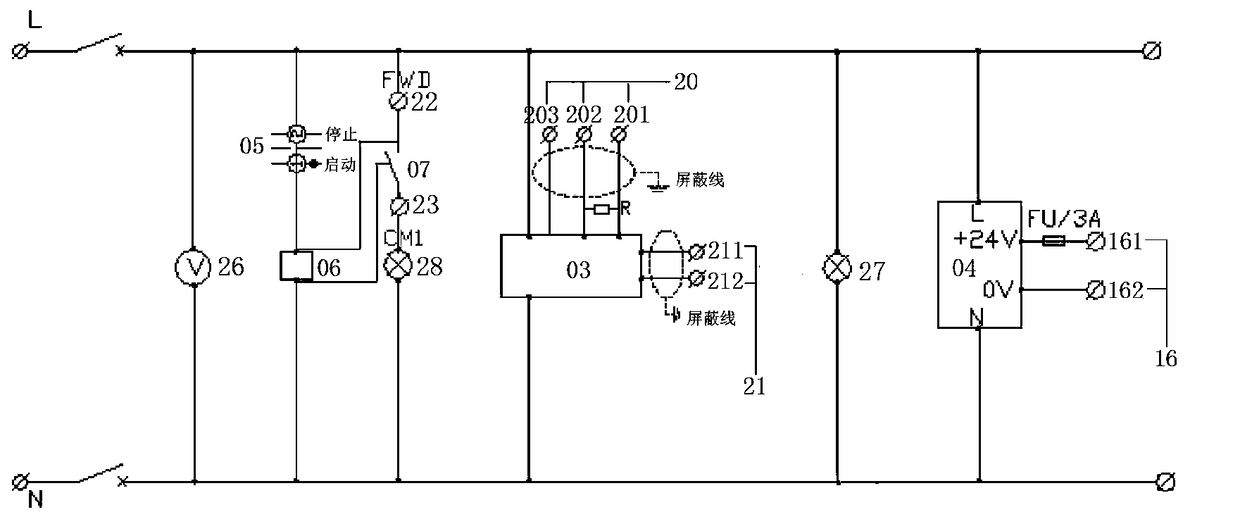

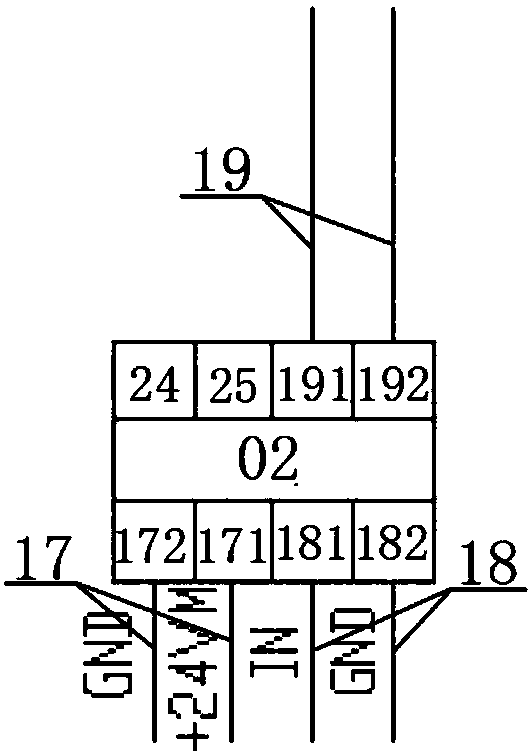

[0023] refer to figure 1 , a blower constant pressure air supply electric control system disclosed in this embodiment, wherein the blower is a Roots blower for supplying air to the flotation cell in the flotation system of a polymetallic beneficiation plant, including: wind pressure transmitter 01, SFD Signal isolator 02, intelligent PID regulator 03, switching power supply device 04, transfer switch 05, electromagnetic relay 06 and frequency conversion start switch 07, wind pressure transmitter 01 is installed in the blower outlet pipe, SFD signal isolator 02, intelligent PID Regulator 03, switching power supply device 04, transfer switch 05, electromagnetic relay 06 and frequency conversion start switch 07 are integrated and installed in the distribution box through the electric control circuit 08, preferably, the distribution box is installed close to the blower inverter 09, refer to figure 2 , the intelligent PID regulator 03, the switching power supply device 04, the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com