A Drainage System of Generator Large Shaft Air Supplement Pipe

A technology of drainage system and air supply pipe, which is applied in the directions of hydropower generation, engine components, machines/engines, etc., can solve the hidden danger of flooded generator accident and the problem of water leaking from the large shaft air supply pipe, so as to prevent falling, ensure the air supply volume, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

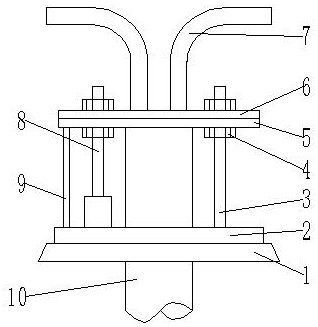

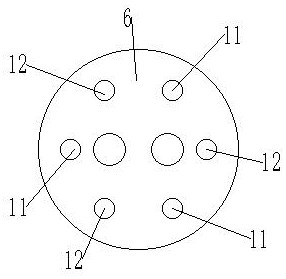

[0045] Such as Figure 1-3 As shown, a drainage system for the large shaft air supply pipe of a generator includes a rotating shaft air supply pipe 10 and a generator cover floor 1; the air inlet of the rotating shaft air supply pipe 10 runs through the generator cover floor 1 and is located on the generator cover floor 1 above; the generator cover floor 1 is provided with an annular support plate 2, and the rotating shaft air supply pipe 10 is located in the round hole of the annular support plate 2; the upper side of the annular support plate 2 is provided with a guide rod 3 and a push-pull rod 8; The upper end of the guide rod 3 and the output shaft of the push-pull rod 8 are connected to the upper pressure plate 6; the upper end of the guide rod 3 and the output shaft of the push-pull rod 8 are connected to the upper pressure plate 6 The connection is provided with a threaded cap 4, and the threaded cap 4 is used to fix the upper platen 6; the upper platen 6 is provided wi...

Embodiment 2

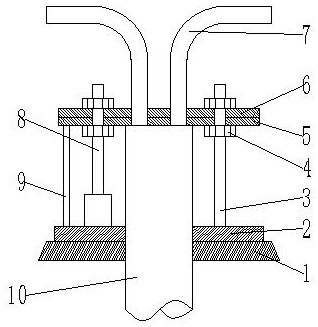

[0053] Such as Figure 4-6 As shown, a drainage system for the large shaft air supply pipe of a generator includes a rotating shaft air supply pipe 10 and a generator cover floor 1; the air inlet of the rotating shaft air supply pipe 10 runs through the generator cover floor 1 and is located on the generator cover floor 1 above; the generator cover floor 1 is provided with an annular support plate 2, and the rotating shaft air supply pipe 10 is located in the round hole of the annular support plate 2; the upper side of the annular support plate 2 is provided with a guide rod 3 and a push-pull rod 8; The upper end of the guide rod 3 and the output shaft of the push-pull rod 8 are connected to the upper pressure plate 6; the upper end of the guide rod 3 and the output shaft of the push-pull rod 8 are connected to the upper pressure plate 6 The connection is provided with a threaded cap 4, and the threaded cap 4 is used to fix the upper platen 6; the upper platen 6 is provided wi...

Embodiment 3

[0066] Different from Embodiments 1 and 2, the distance H between the annular support plate 2 and the sealing plate 5, the length L of the output shaft of the push-pull rod, the diameter R1 of the draft tube, and the diameter R2 of the air supply tube satisfy the following requirements: relation:

[0067] H·R2=α·M·L·R1;

[0068] In the formula: the units of H, L, R1 and R2 are cm;

[0069] M is the number of draft tubes;

[0070] α is the correlation coefficient, and the value range is 5.2-8.4.

[0071] Since it takes a certain amount of time for the sensor to transmit the signal to the processor, when α is less than 5.2, the sealing delay of the rotating shaft air supply pipe 10 is likely to occur, resulting in the phenomenon that the rotating shaft air supply pipe 10 is not sealed yet, and the rotating shaft air supply pipe 10 leaks water. When α is greater than 8.4, it is easy to have a large amount of water coming out of the rotating shaft air supply pipe 10, which lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com