SiOxNy-based synapse optically reading device and preparation method thereof

A neural synapse and optical reading technology, which is applied in optical components, biological neural network models, nanotechnology for materials and surface science, etc. Problems such as large interference, to achieve the effect of device size reduction and large bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

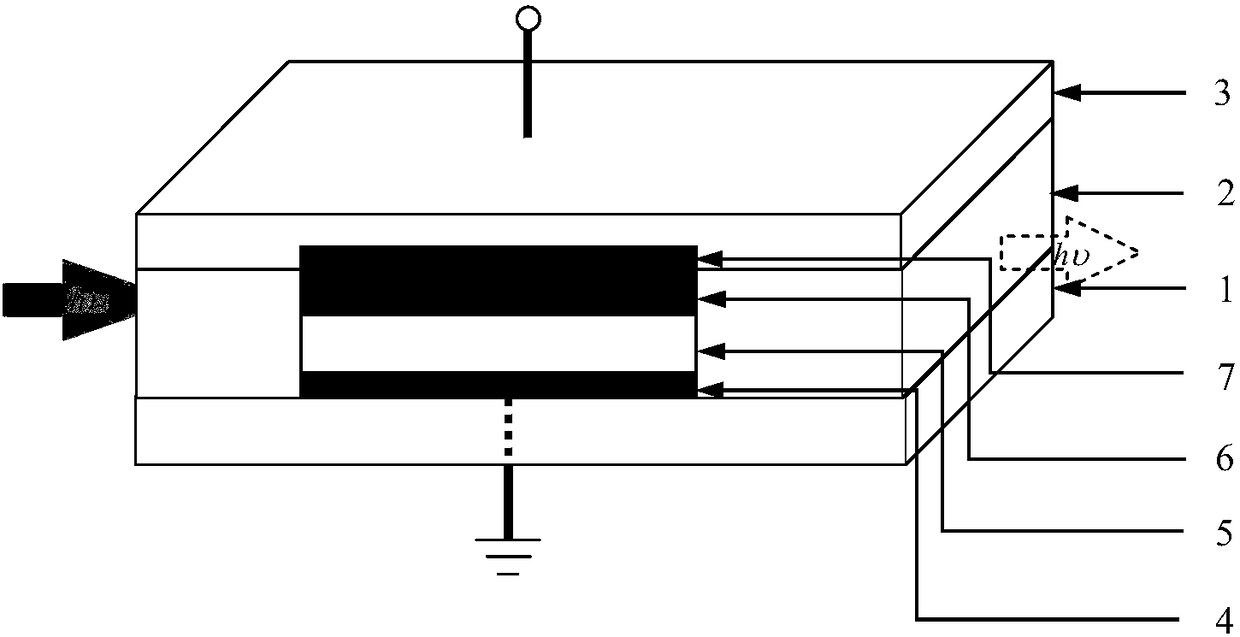

[0049] Such as figure 1 As shown, this embodiment provides a SiO-based x N y Optically readable synaptic devices, including surface plasmon waveguides and memristors;

[0050] The surface plasmon waveguide has "second metal layer 3 / SiN x Vertical three-layer structure of dielectric layer 2 / first metal layer 1";

[0051] The memristor has a vertical four-layer structure of "upper electrode 7 / second resistive layer 6 / first resistive layer 5 / lower electrode 4" arranged sequentially from top to bottom;

[0052] The memristor is embedded in the surface plasmon waveguide, the first resistive layer 5 and the second resistive layer 6 of the memristor serve as the optical signal propagation channel and the SiN of the surface plasmon waveguide x The medium layer 2 is connected horizontally.

[0053] The top of the upper electrode 7 is located inside the second metal layer 3 , which can reduce the loss of a part of the optical signal.

[0054] In this example,

[0055] The first r...

Embodiment 2

[0069] The difference between this embodiment and embodiment 1 is that

[0070] The thickness of the first metal layer 1 and the second metal layer 3 is 20nm;

[0071] The first resistive switch layer 5 is intrinsic SiO x N y Thin film, thickness is 50nm, adopts reactive magnetron sputtering method to obtain;

[0072] The second resistance variable layer 6 is SiO containing copper nanoparticles x N y The thin film, with a thickness of about 30nm and a copper content of 45% (volume percentage), is obtained by a co-sputtering method.

Embodiment 3

[0074] The difference between this embodiment and embodiment 1 is that

[0075] The thickness of the first metal layer 1 and the second metal layer 3 is 15nm;

[0076] The first resistive switch layer 5 is intrinsic SiO x N y Thin film, thickness is 40nm, adopts reactive magnetron sputtering method to obtain;

[0077] The second resistance variable layer 6 is SiO containing aluminum nanoparticles x N y A thin film with a thickness of about 40nm and an aluminum content of 40% (volume percentage) is obtained by a co-sputtering method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap