Bottom box connecting component, bottom box connecting structure and mounting method thereof

A technology for connecting components and bottom boxes, which is applied in the direction of electrical components, etc., can solve the problems of affecting the appearance, not being firmly embedded, and increasing the difficulty of installing switch surfaces or socket panels, etc., to achieve convenient and fast installation, good decoration quality, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

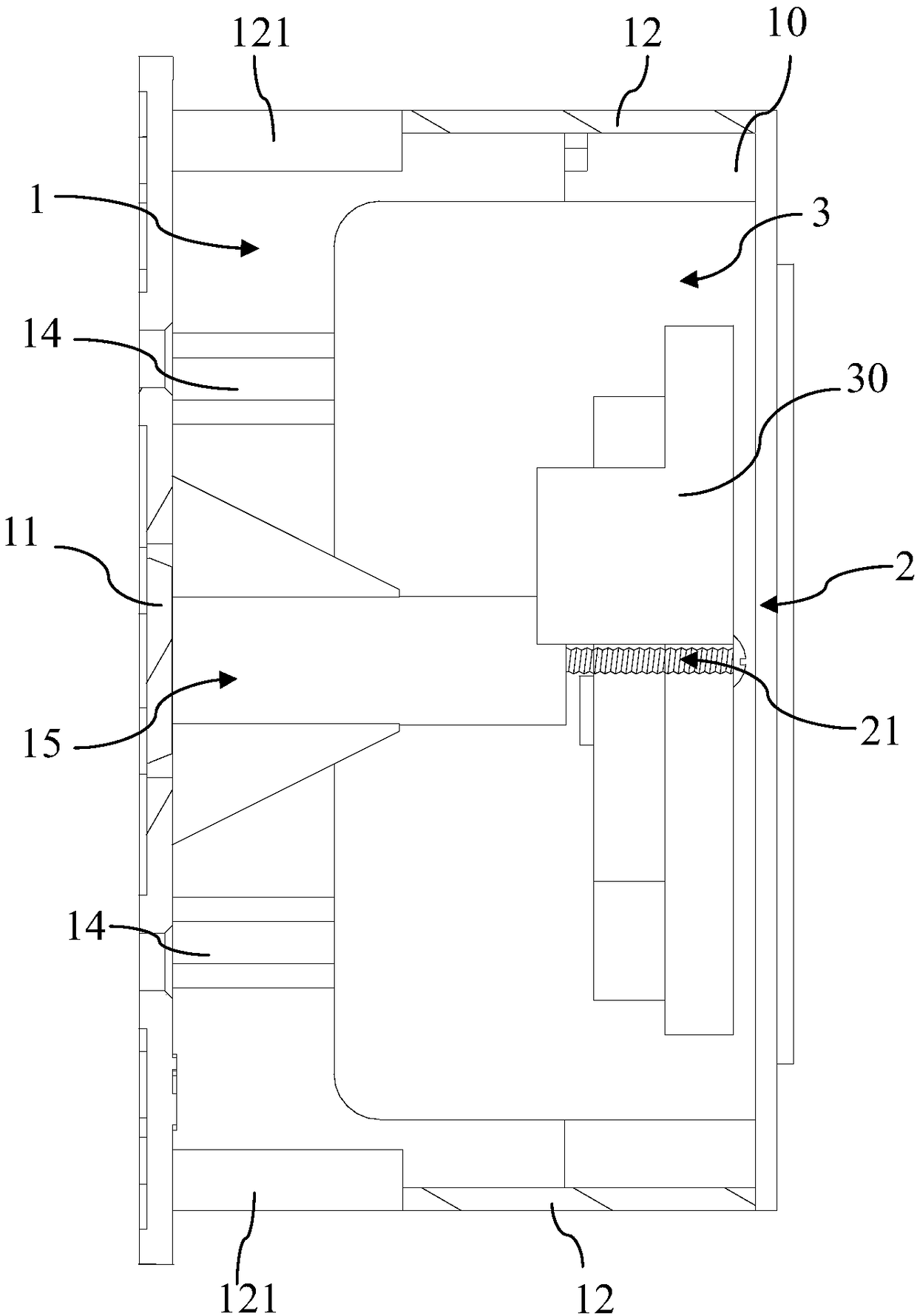

[0067] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

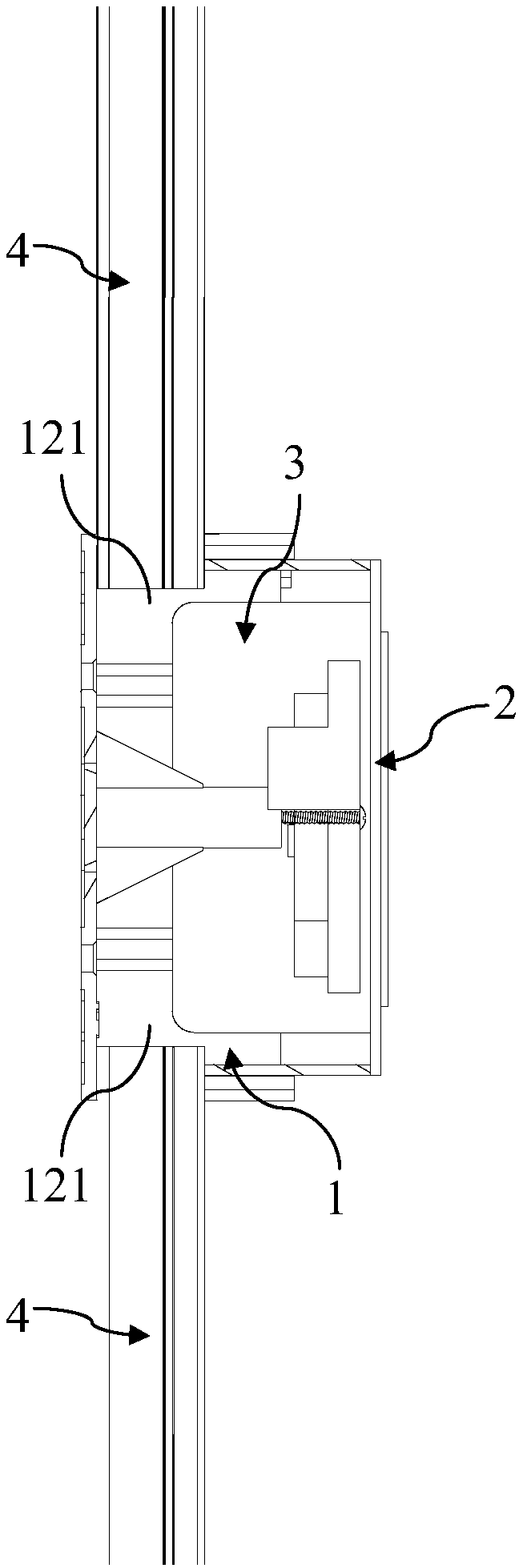

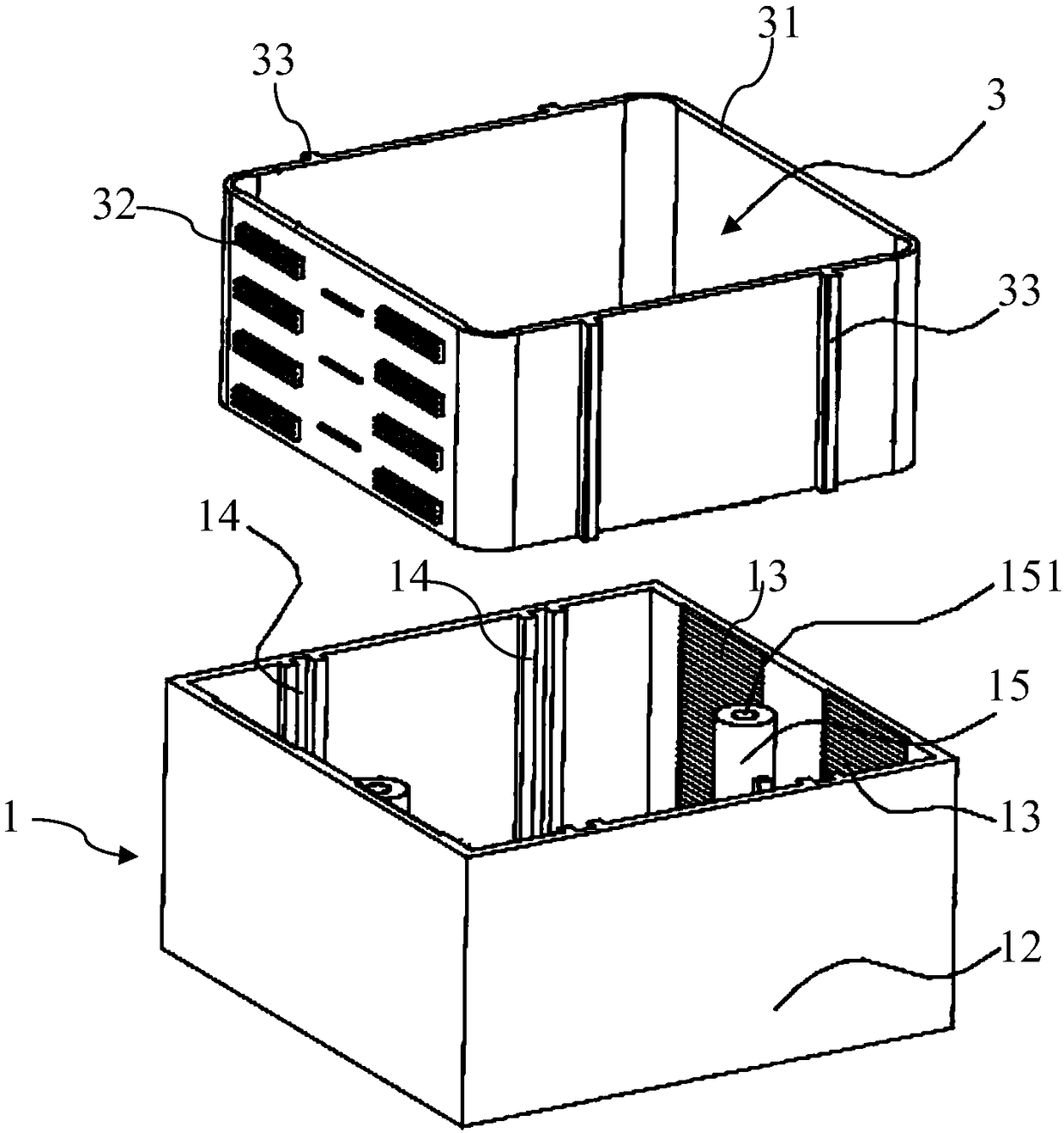

[0068] Such as Figure 1-3 As shown, a bottom box connecting member provided by an embodiment of the present invention includes a telescopic bottom box and a wire groove 4 connected to the telescopic bottom box.

[0069] The telescopic bottom box includes a bottom box 1 , a panel 2 and a sliding box 3 located inside the bottom box 1 and capable of protruding from the bottom box opening 10 of the bottom box 1 .

[0070] The bottom box 1 includes a bottom box bottom pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com