Sterilizer for lily bulbs

A sterilizer and lily technology, applied in the field of agricultural machinery, can solve problems such as difficulty in realizing large-scale and industrialized production, economic loss of lily industry, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

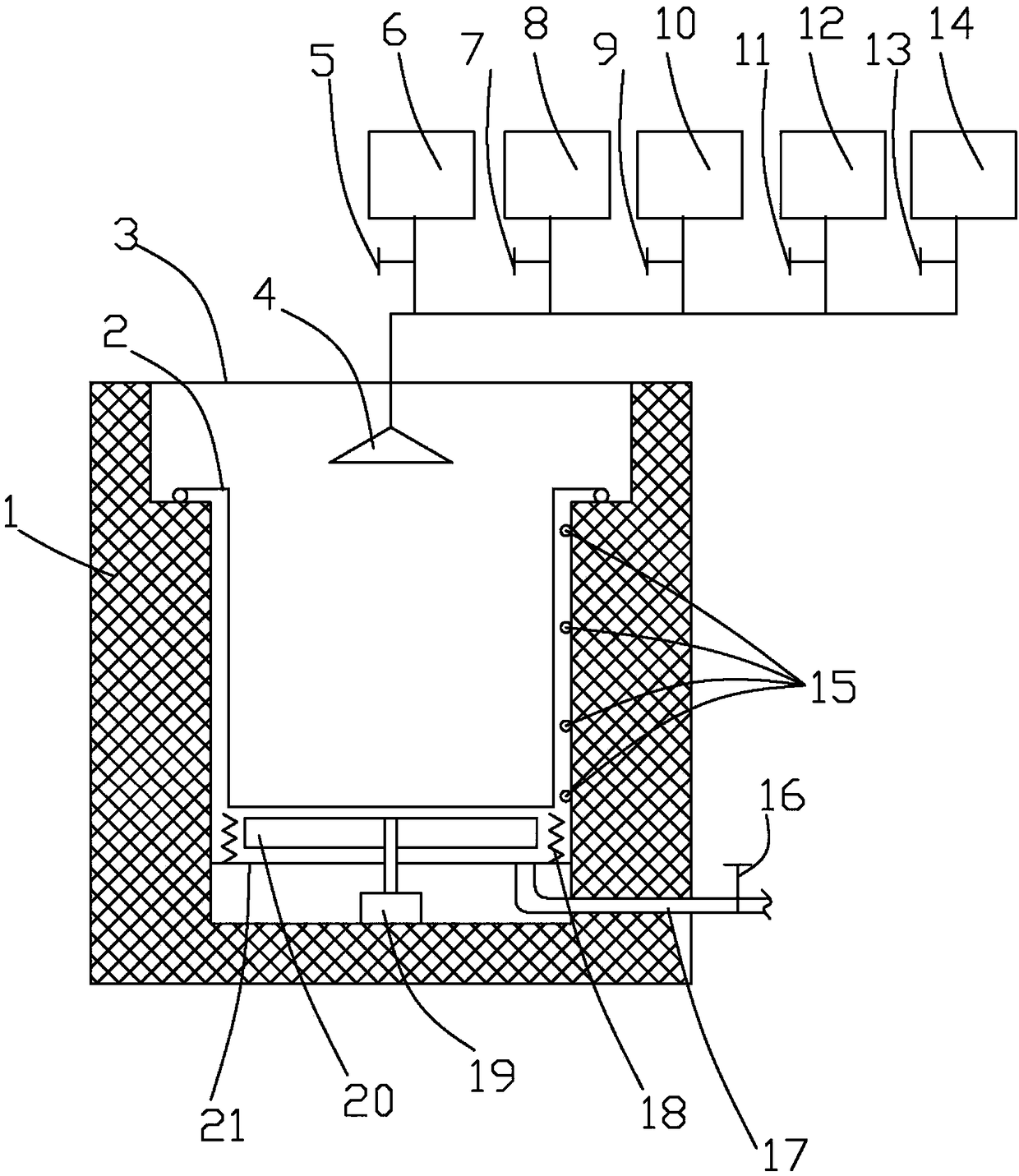

[0023] Such as figure 1 As shown, the present embodiment provides a lily bulb sterilizer, comprising a box body 1, a box cover 3, a lily basket 2, a nozzle 4, a first liquid tank 6, a second liquid tank 8, a third liquid tank 10, a Four liquid tanks 12 and the fifth liquid tank 14; the box cover 3 is arranged on the top of the box body 1, the lily basket 2 is arranged in the box body 1, and the lily basket 2 is used to hold lily bulbs The spray head 4 is arranged on the tank cover 3 and is located inside the box body 1; the spray head 4 is connected to the first liquid tank 6, the second liquid tank 8, and the third liquid tank 10 , the fourth liquid tank 12 and the fifth liquid tank 14 are respectively connected by pipelines.

[0024] In this specific embodiment, a partition 21 is provided at the inner bottom of the box 1; a motor 19 is provided below the partition 21, and the power output shaft of the motor 19 passes through the partition 21, and the power The end of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com