A horizontal air-conditioning coil machine motor production shaft derusting recovery device

A technology for air conditioning coils and recycling devices, which is applied to grinding/polishing safety devices, metal processing equipment, manufacturing tools, etc., can solve problems such as low efficiency, poor effect, and rust on the surface of the rotating shaft, and achieves improved versatility, Improve the effect and avoid the effect of grinding dead corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

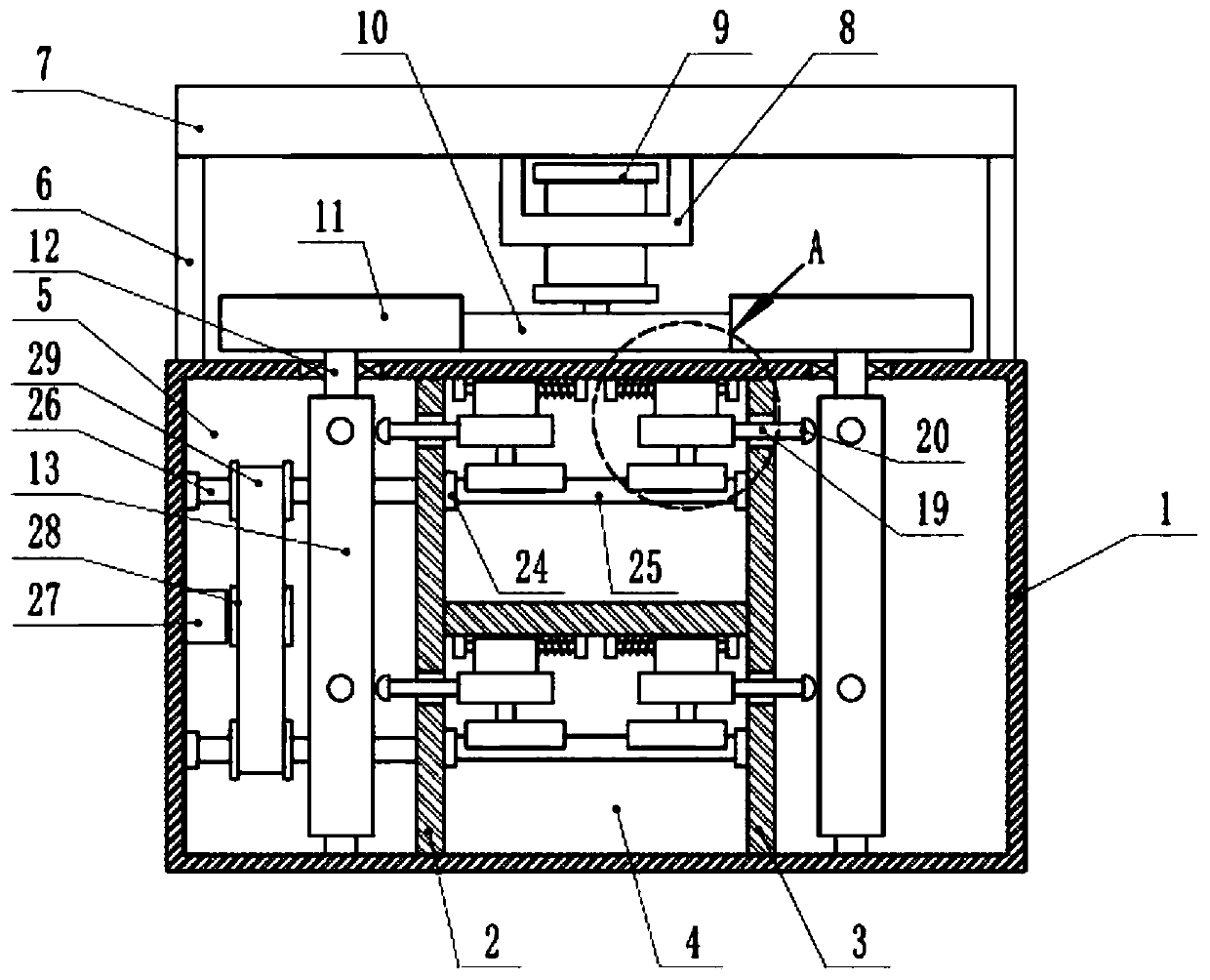

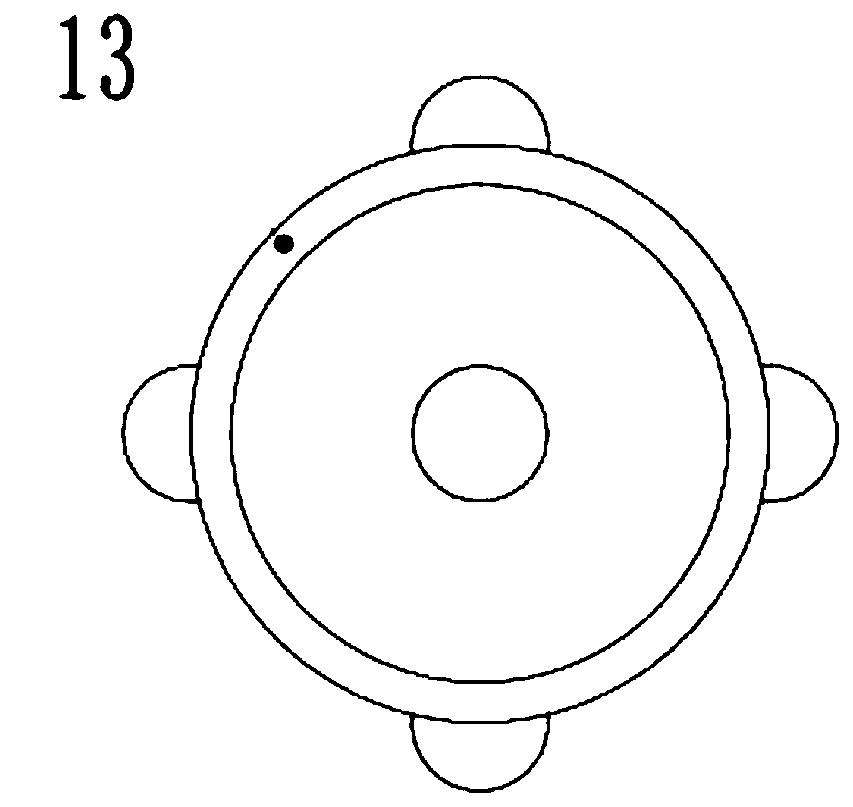

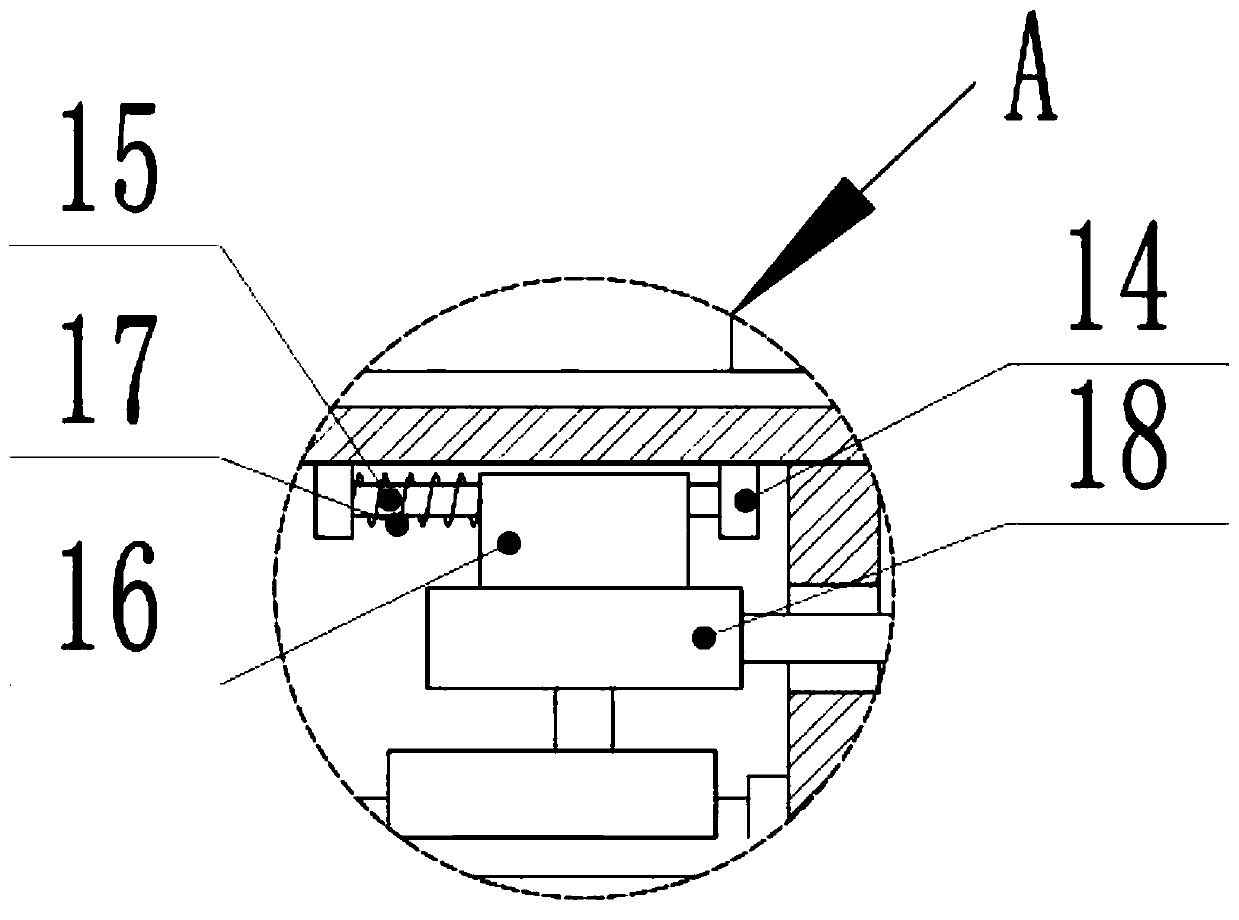

[0022] see Figure 1-4 , a horizontal air-conditioning coil machine motor production shaft rust removal recovery device, including a cabinet 1, a rust removal chamber 4, a device chamber 5, a first drive motor 9 and a second drive motor 27, the inside of the cabinet 1 is vertical The first partition 2 and the second partition 3 are installed, and the rust removal chamber 4 is formed between the first partition 2 and the second partition 3. The first partition 2 and the second partition 3 are connected with the left and right sides of the chassis 1. A device cavity 5 is formed between the inner walls, and a pillar 6 is symmetrically welded on the upper side of the chassis 1, and a top cover 7 is also provided on the upper side of the pillar 6, and the pillar 6 and the top cover 7 are also connected by welding, and the top cover 7 is lowered The sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com