Thermal correcting connection assembly

A technology for connecting components and thermal correction, applied in the direction of connecting components, shrinking connections, pins, etc., can solve problems such as damage to tooling, difficulty in disassembly, etc., and achieve the effects of saving resources, avoiding difficulty in disassembly, and facilitating hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

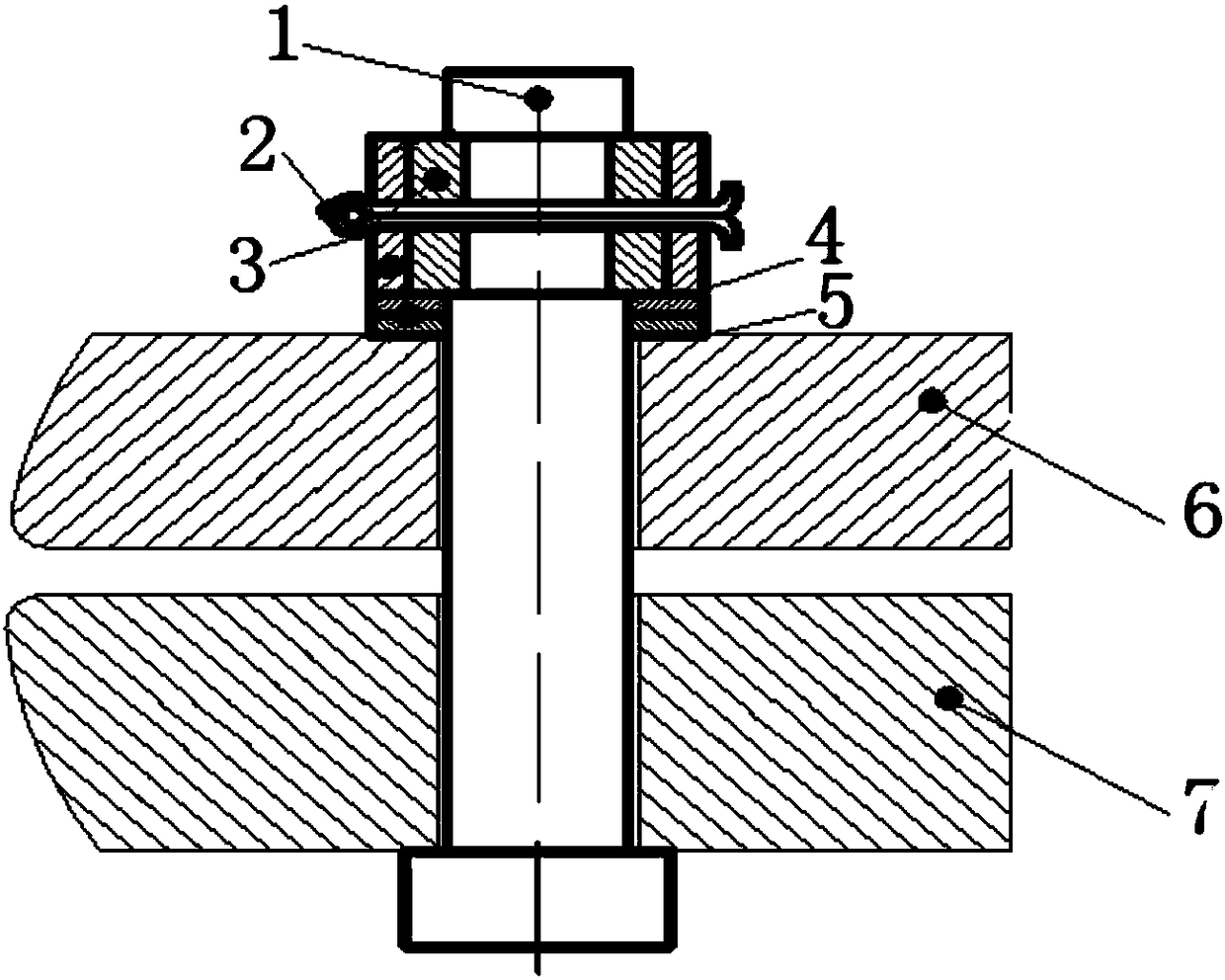

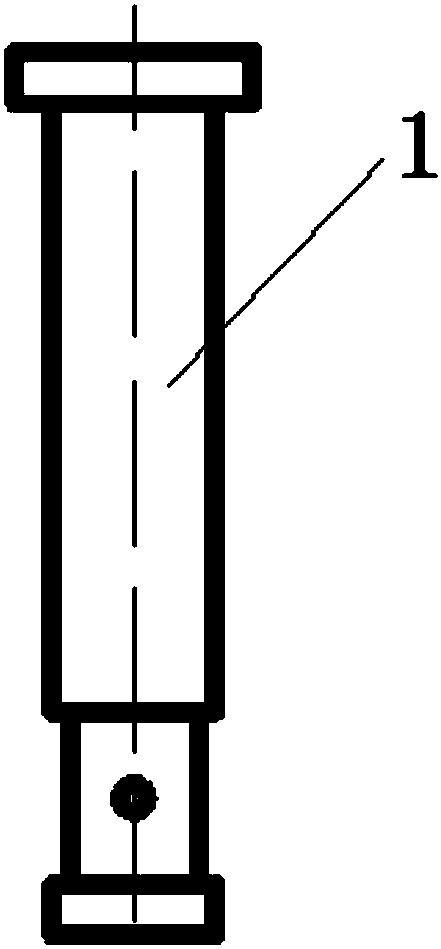

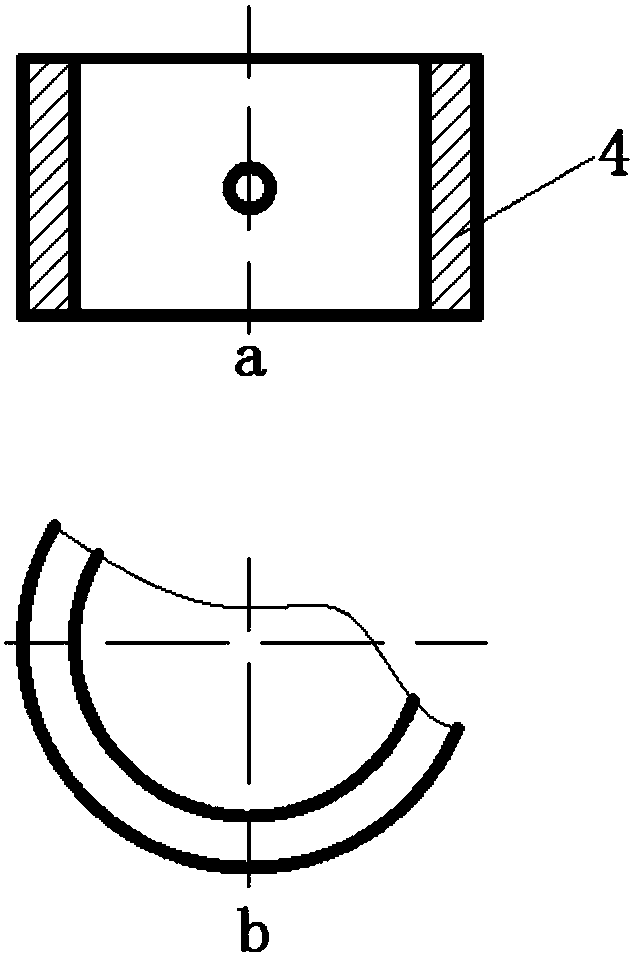

[0024] This embodiment is a connection assembly for thermally correcting warping of hemispherical parts with a wall thickness less than 10mm, including a connecting rod 1 , a cotter pin 2 , a clamp 3 , a snap ring 4 and an adjustment pad 5 . Wherein, the clamp 3 is embedded in the installation groove at the upper end of the connecting rod 1, and the clamp ring 4 is sleeved on the outer circumferential surface of the clamp; the cotter pin 2 passes through the clamp ring, the clamp and the connecting rod, and the The three are connected. The distance between the heat-shaping connection component and the surface of the connected part is adjusted by adjusting the pad 5 .

[0025] The length of the shaft of the connecting rod 1 is greater than the sum of the heights of the connected upper platen 6 and the lower platen 7; the shaft of the connecting rod passes through the center hole of the upper platen 6 and the center hole of the lower platen 7 . The outer peripheral surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com