Split-type car hub nut

An automobile hub and split technology, which is applied in the field of auto parts, achieves the effects of high-strength mechanical properties, simple structure and safety assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

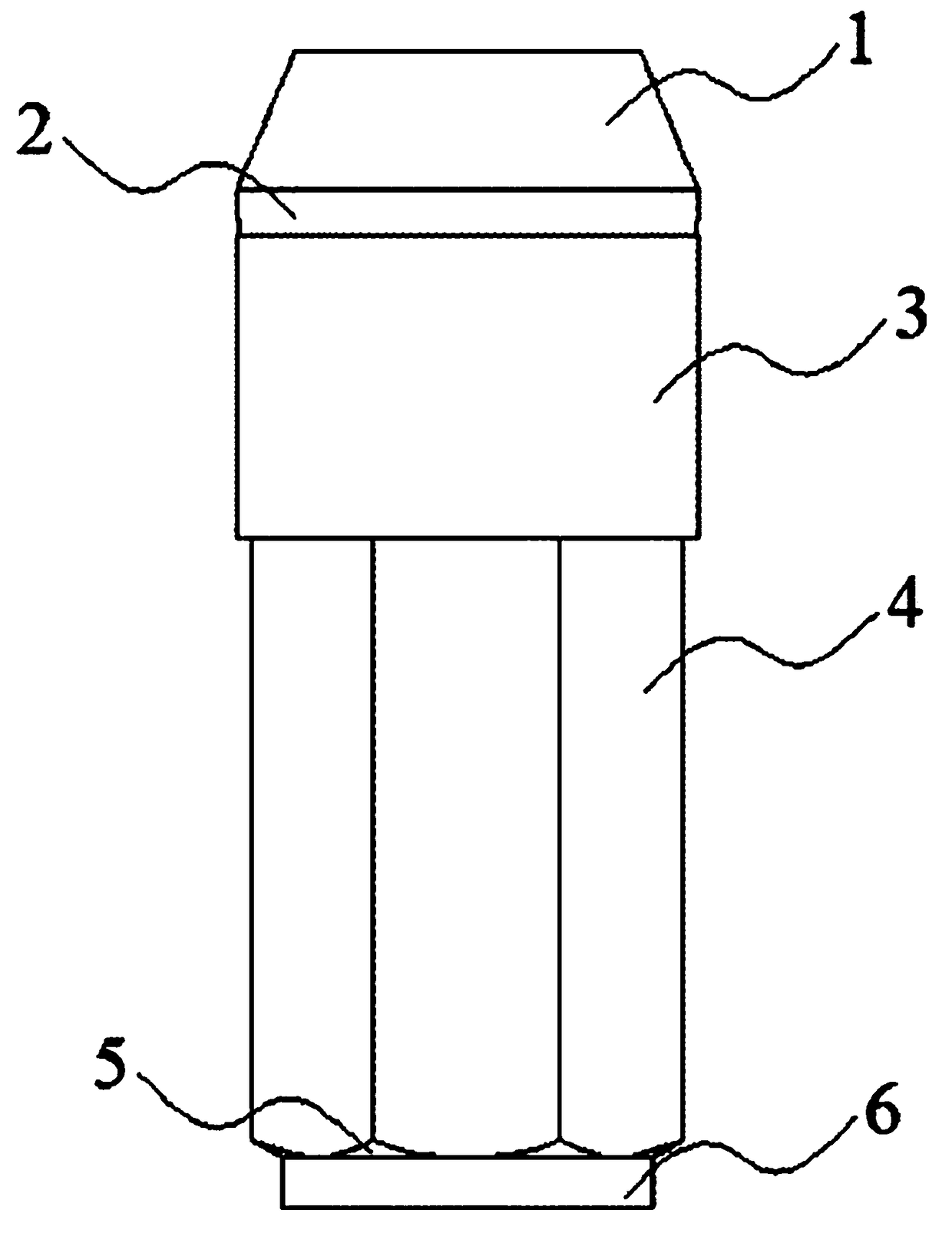

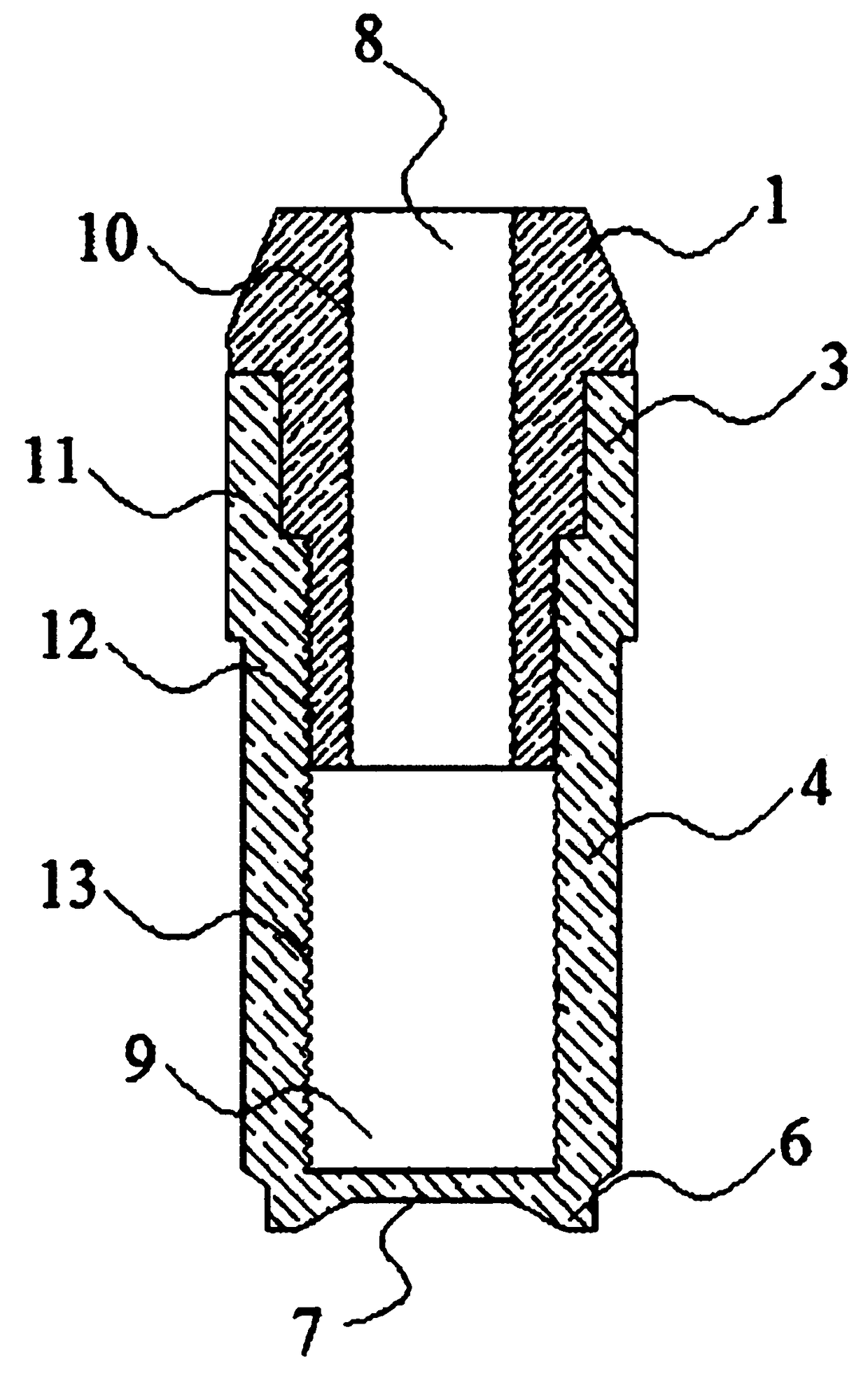

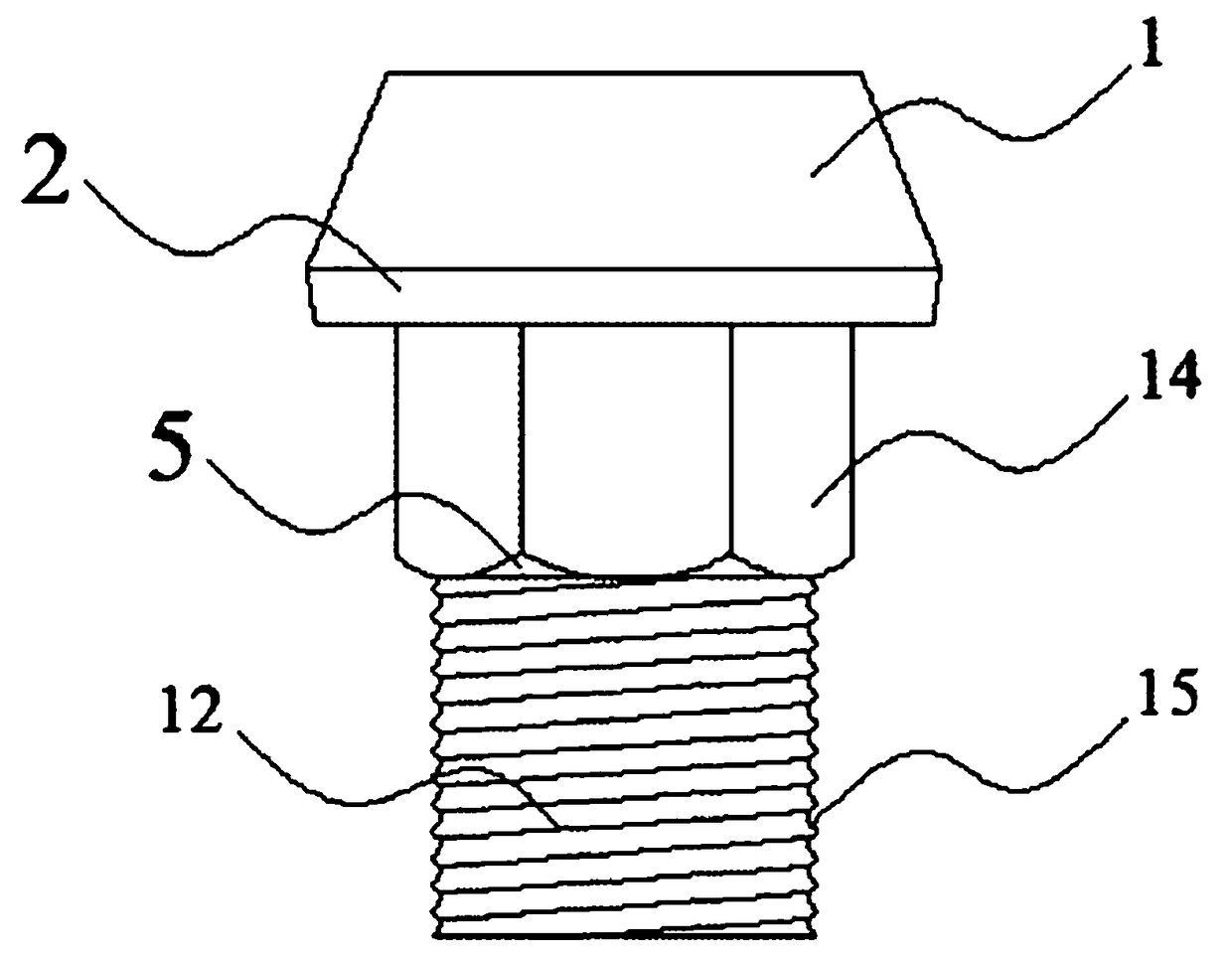

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a split type automobile hub nut includes a nut shell and a nut inner core, and a connection and cooperation structure is provided between the nut shell and the nut core, and the connection and cooperation structure is a threaded connection. The material of the nut shell is an aluminum alloy material, and the material of the nut core is high-hardness alloy steel, and the nut shell includes a nut shell head 3, a nut shell connecting arm 4 and a nut shell bottom 6 , the nut shell head 3, the nut shell connecting arm 4 and the nut shell bottom 6 are integrally connected, and the nut core includes a nut core head 1 and a nut core connecting portion 2 , the nut core connecting arm 14 and the nut core bottom 15, between the nut core head 1, the nut core connecting portion 2, the nut core connecting arm 14 and the nut core bottom 15 All in one connection.

[0025] Such as figure 2 Shown, as a kind of preferr...

Embodiment 2

[0032] The main feature of this embodiment 2 is: the thread pitches of the inner thread 10 of the inner core of the nut, the outer thread 12 of the inner core of the nut and the inner thread 13 of the outer shell of the nut are all 1.25mm. All the other features are the same as in Example 1.

[0033] In summary, a split type automobile hub nut designed by the present invention has simple structure, convenient use, and low cost. The nut shell and the nut core are connected by threads, and the material of the nut shell is aluminum alloy. The material of the core of the nut is high-hardness alloy steel. The aluminum alloy shell has various colors and styles to meet individual needs. The shell part can be replaced at any time according to individual needs, while the core part does not need to be replaced, saving resources. The hardness requirement of the nut can also overcome the problem of single color of the nut. The invention uses this split-type automobile wheel nut to fix the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com