Reinforced Gaskets for Fuel Cells

A sealing gasket and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as increased processing costs, higher assembly precision requirements, excessive bending and deformation of membrane electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

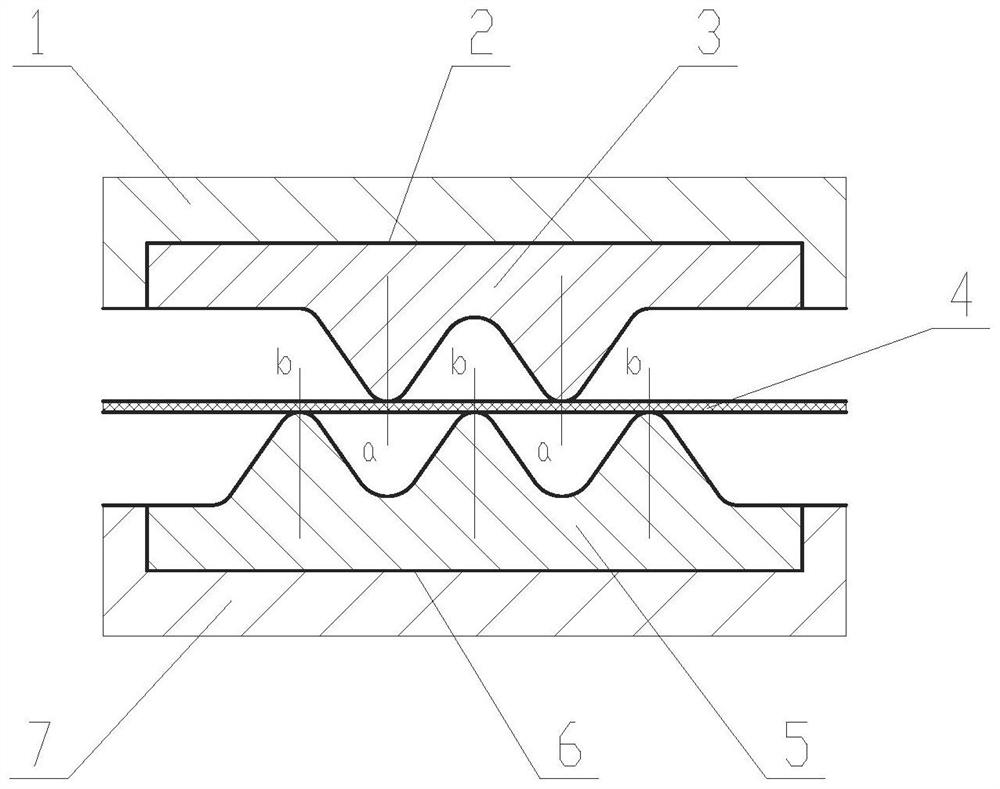

[0027] The reinforced sealing gasket for fuel cells of the present invention will be further described below in combination with specific examples.

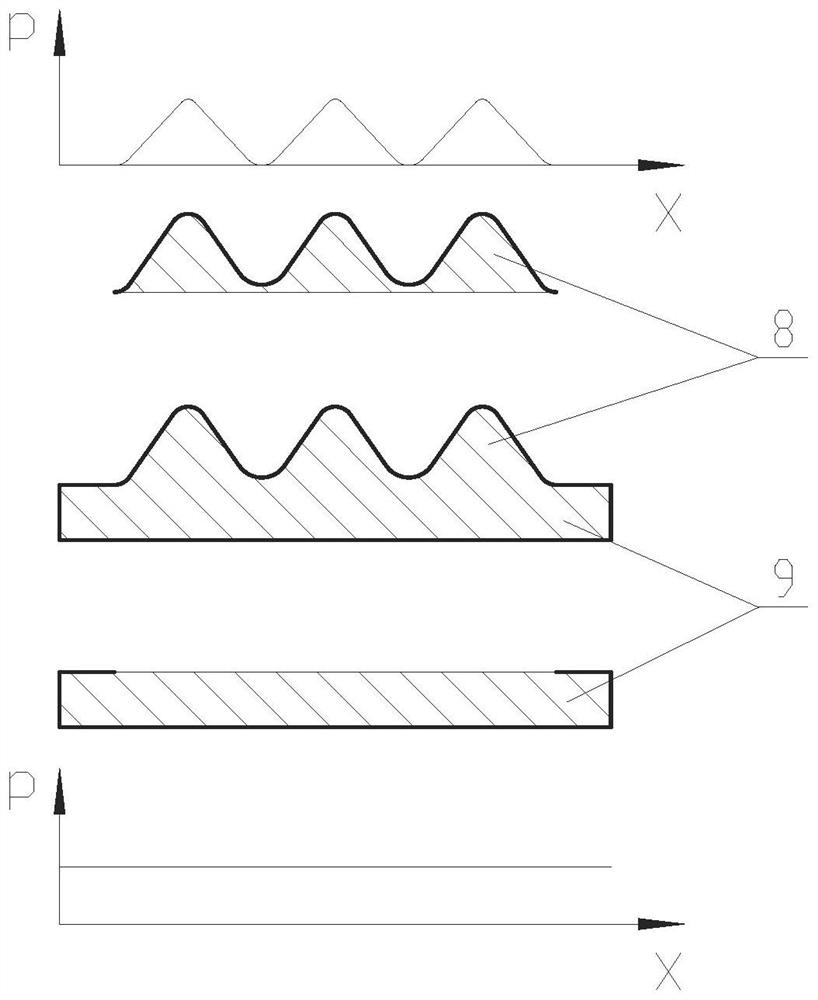

[0028] The enhanced sealing gasket for the fuel cell of the present invention has a width of 3 mm, a height of the sealing base of 0.5 mm, and a height of the sealing boss of 0.6 mm. Three identical sealing bosses are arranged on the sealing base, the cross-sectional shape of the sealing bosses is an equilateral triangle, and the distance between each sealing boss is 0.8 mm. Due to the requirements of enhanced sealing gasket processing and optimized force, the necessary rounded corner structure is set on the sealing gasket. see details figure 2 .

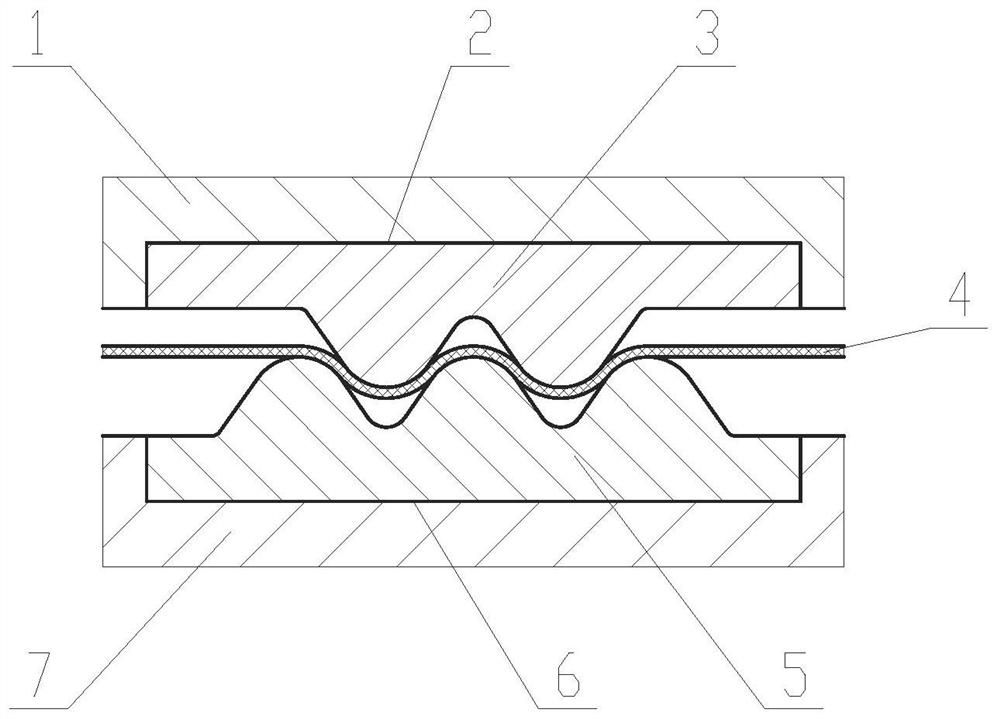

[0029] The enhanced sealing gasket for fuel cells of the present invention is used in pairs, the width of the two enhanced sealing gaskets is 3 millimeters, the height of the sealing base is 0.5 millimeters, and the height of the sealing boss is The cross-sectional shapes of the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com