Holding type cable tightening clamp

A technology of tightening wire clips and plying plates, which is used in electrical components, cable installation, overhead installation, etc., can solve the problems of cable overheating, randomness, leakage and short circuit, etc., to prevent the extension distance from being too long and the adjustment range is large. , the effect of preventing fallout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

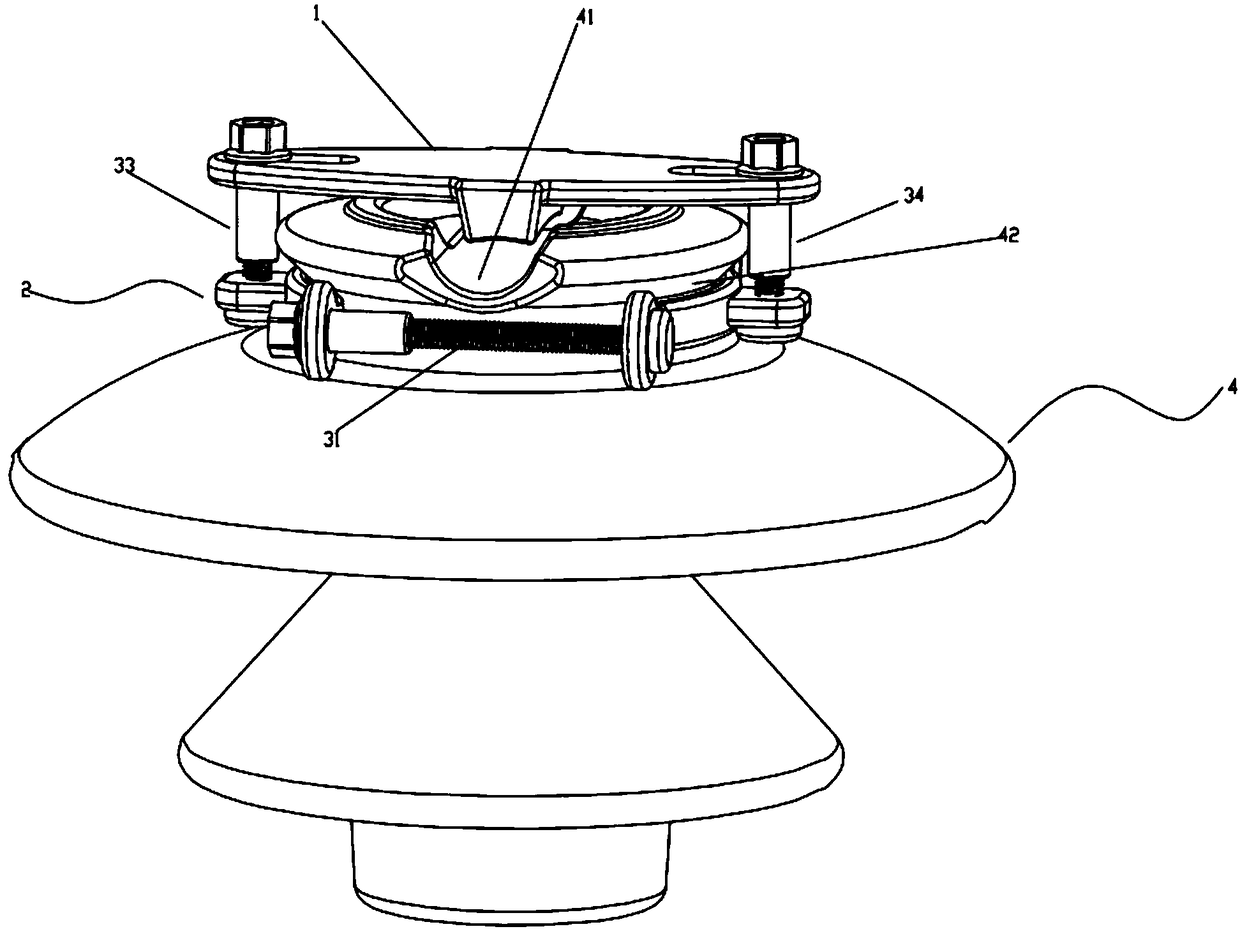

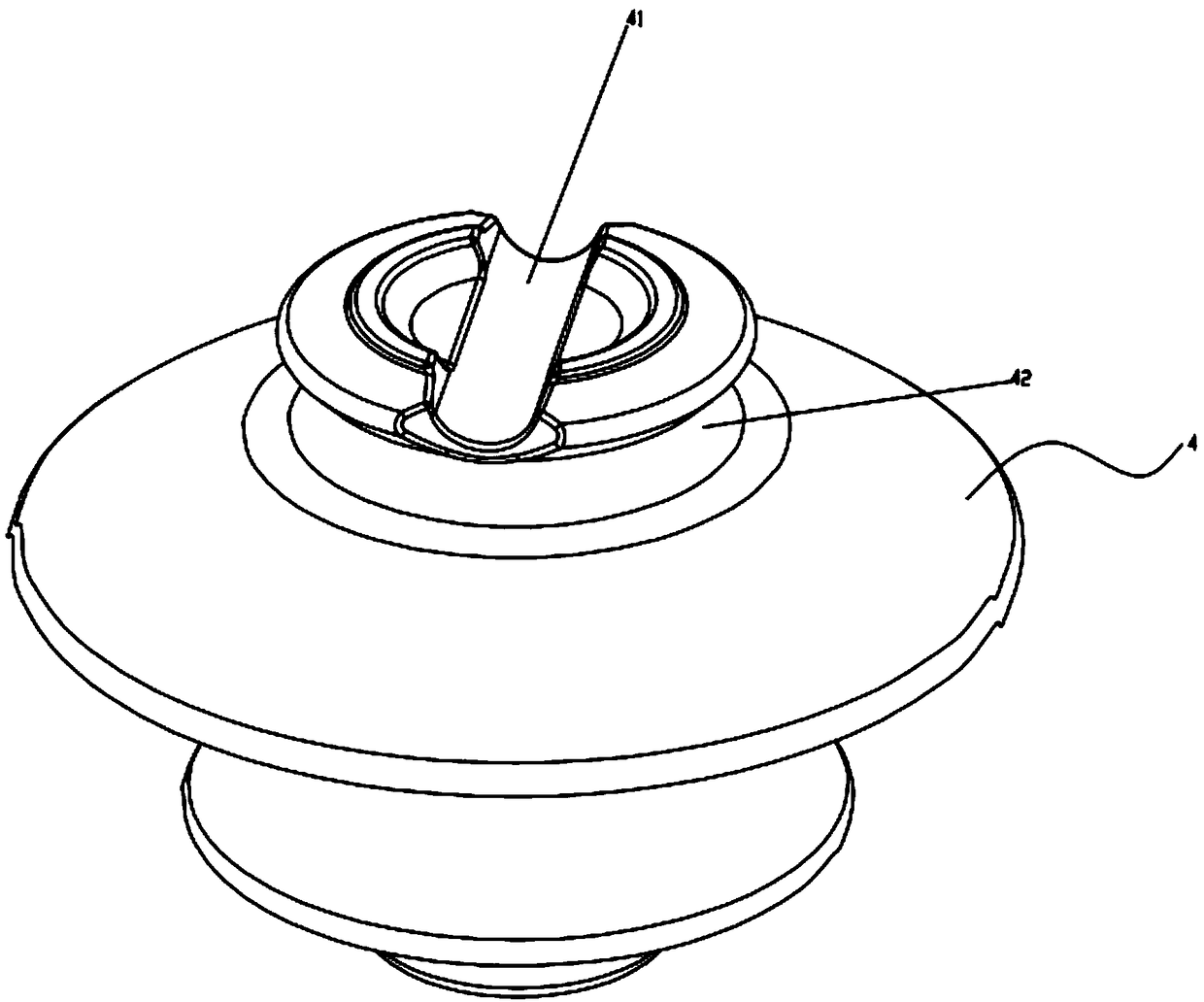

[0019] Such as Figure 3-4 As shown, both the pin insulator 4 and the post insulator 5 are provided with a top groove 41 and an annular side groove 42 .

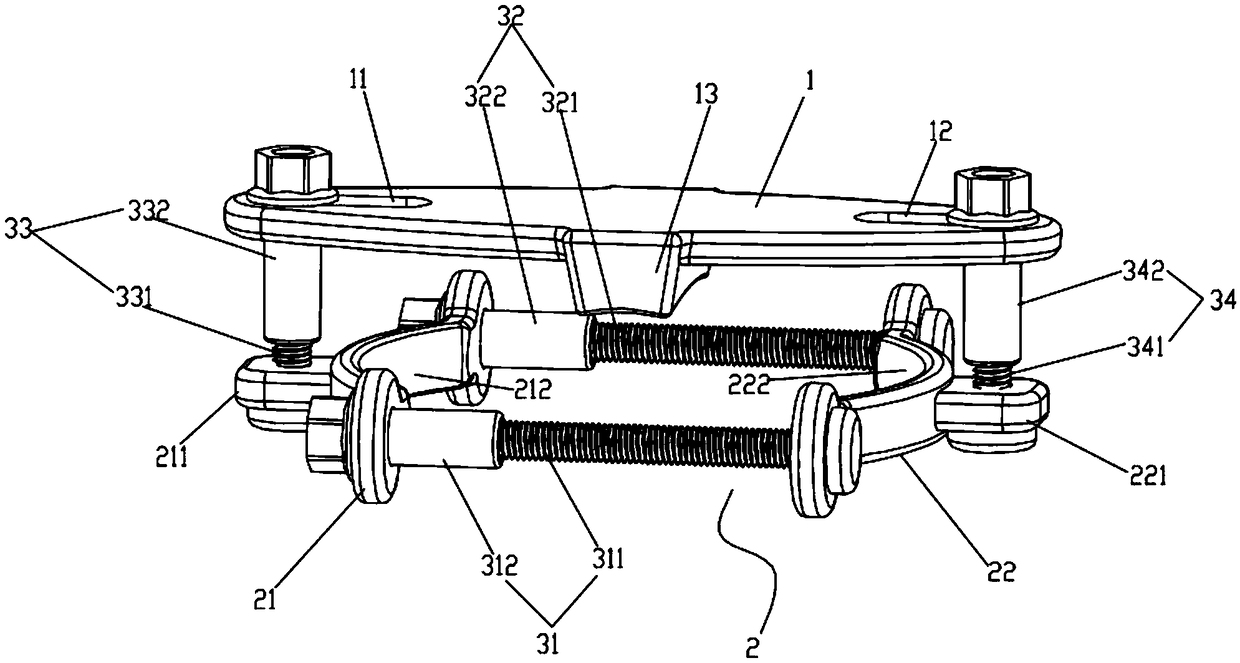

[0020] Such as Figure 1-2 As shown, an embracing type tightening clamp includes a crimping plate 1 and an embracing plate assembly 2, and the embracing plate assembly 2 includes a first clamping plate 21 and a second clamping plate 22 arranged oppositely, the first clamping plate 21 One end and one end of the second clamping plate 22 are movably connected through the first connecting piece 31, and the other end of the first clamping plate 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com