Method for water level detection of water purification tank and system

A water level detection and water level technology, which is applied in the washing machine/washing machine of tableware, parts of the washing machine/rinsing washing machine for tableware, cleaning equipment, etc. The effect of protecting energy saving, protecting ultrasonic components, reducing run time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

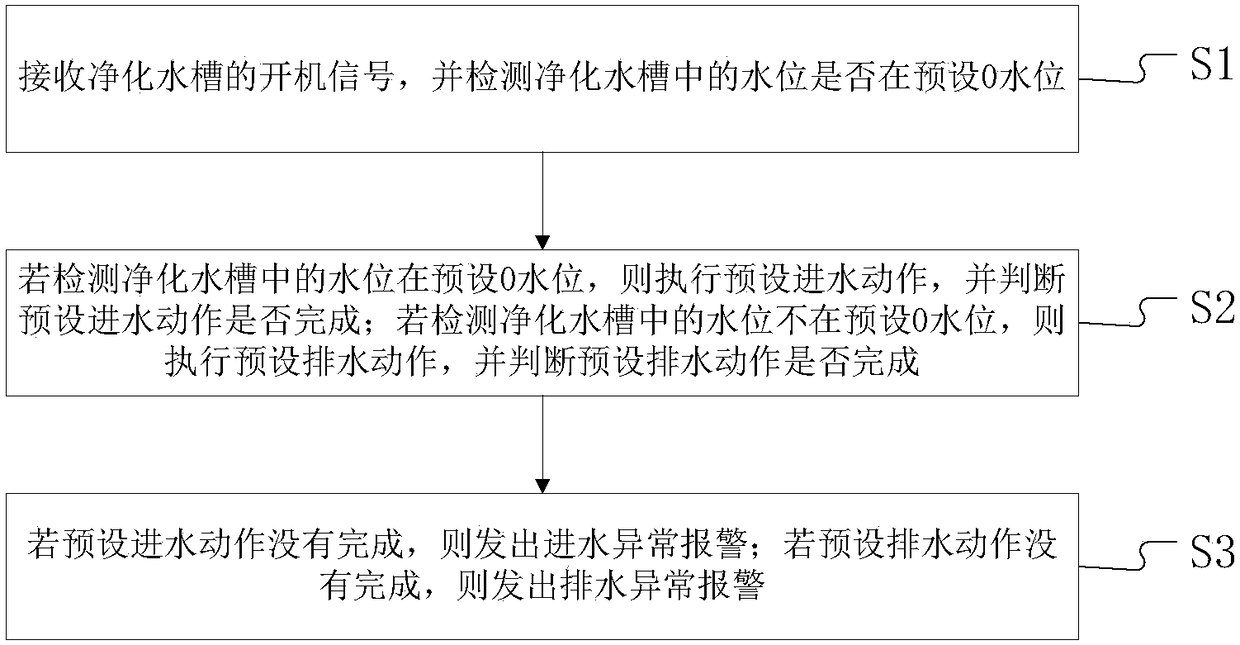

[0042] This embodiment provides a method for detecting the water level of a purified water tank, such as Figure 1 to Figure 2 As shown, this method includes:

[0043] S1: Receive the power-on signal of the purified water tank, and detect whether the water level in the purified water tank is at the preset 0 water level;

[0044] S2: If it is detected that the water level in the purified water tank is at the preset 0 water level, execute the preset water intake action, and judge whether the preset water intake action is completed; if the detected water level in the purified water tank is not at the preset 0 water level, perform the preset operation Drainage action, and judge whether the preset drainage action is completed;

[0045] S3: If the preset water inflow action is not completed, an abnormal water inflow alarm will be issued; if the preset water discharge action is not completed, an abnormal drainage alarm will be issued.

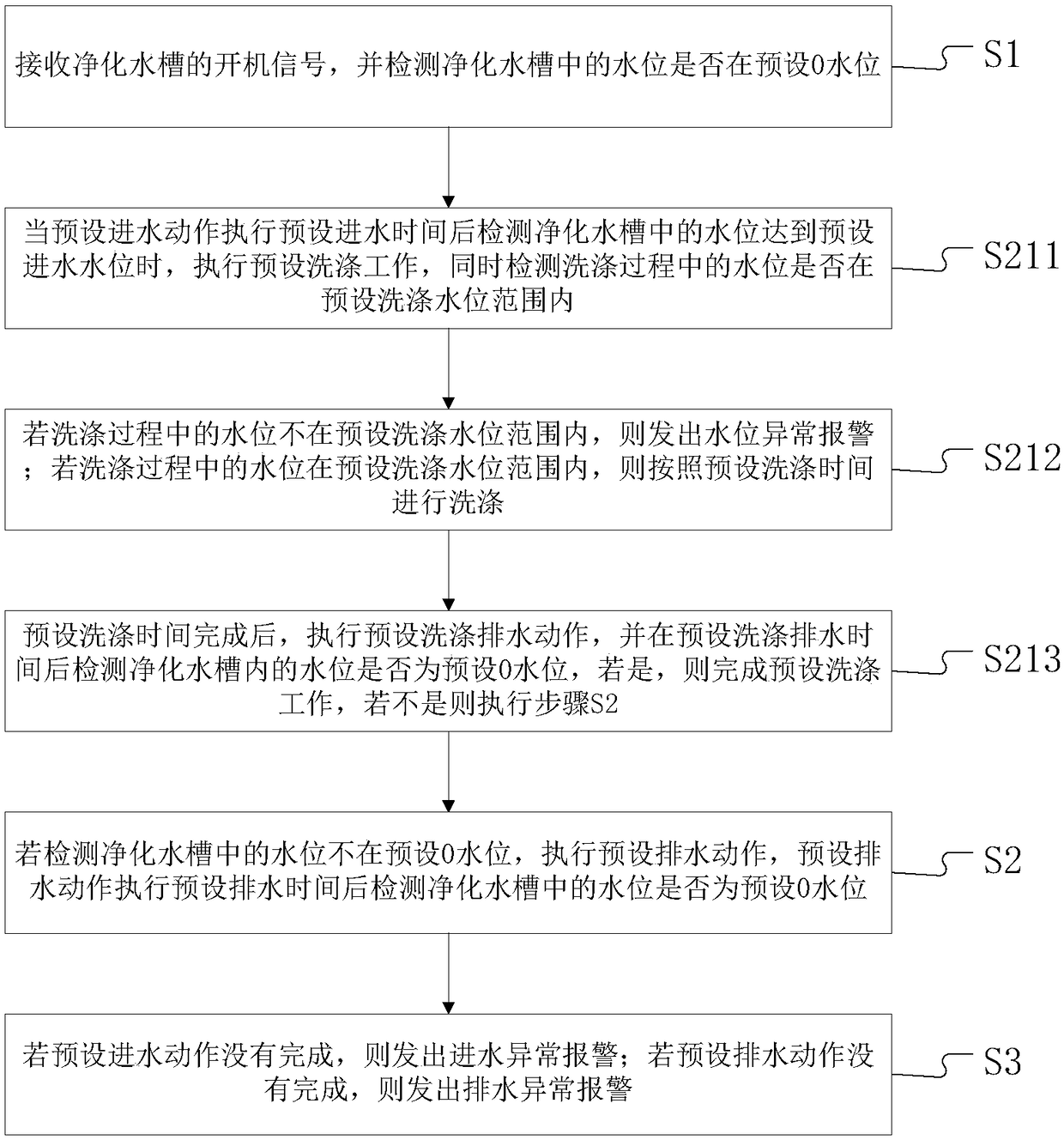

[0046] Further, step S2 includes:

[0047] S...

Embodiment 2

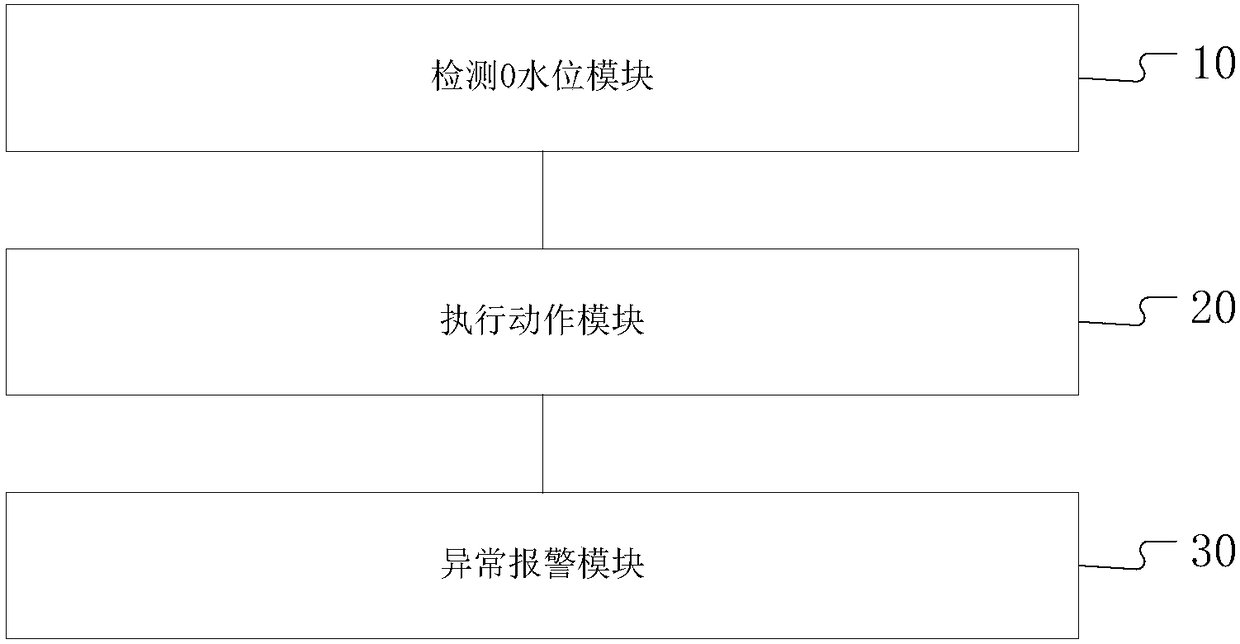

[0065] This embodiment provides a system for detecting the water level of a purified water tank, such as Figure 3 to Figure 4 As shown, the system includes:

[0066] The 0 water level detection module is used to receive the power-on signal of the purified water tank, and detect whether the water level in the purified water tank is at the preset 0 water level;

[0067] The execution action module is used to execute the preset water intake action when detecting that the water level in the purified water tank is at the preset 0 water level, and judge whether the preset water intake action is completed; execute when the detected water level in the purified water tank is not at the preset 0 water level Preset the drainage action, and judge whether the preset drainage action is completed;

[0068] The abnormal alarm module is used to issue an abnormal water inflow alarm when the preset water inflow action is not completed; and issue an abnormal drainage alarm when the preset water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com