Full gear surface shape modification method for internal gear powerful gear honing

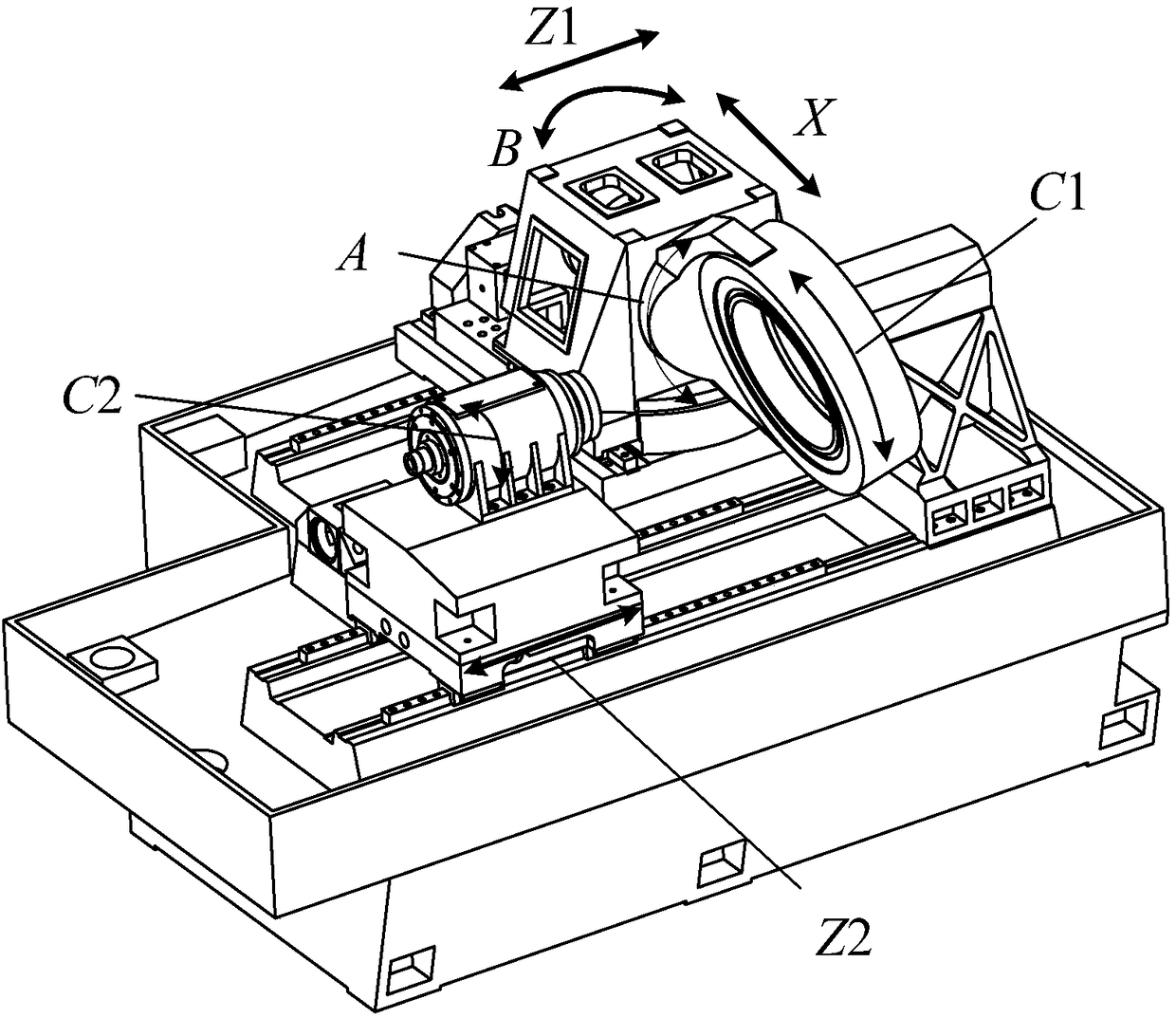

A powerful, internal tooth technology, applied in the direction of components with teeth, gear teeth, belt/chain/gear, etc., can solve the problem of high price, shorten the manufacturing cycle, shorten the development cycle and reduce the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

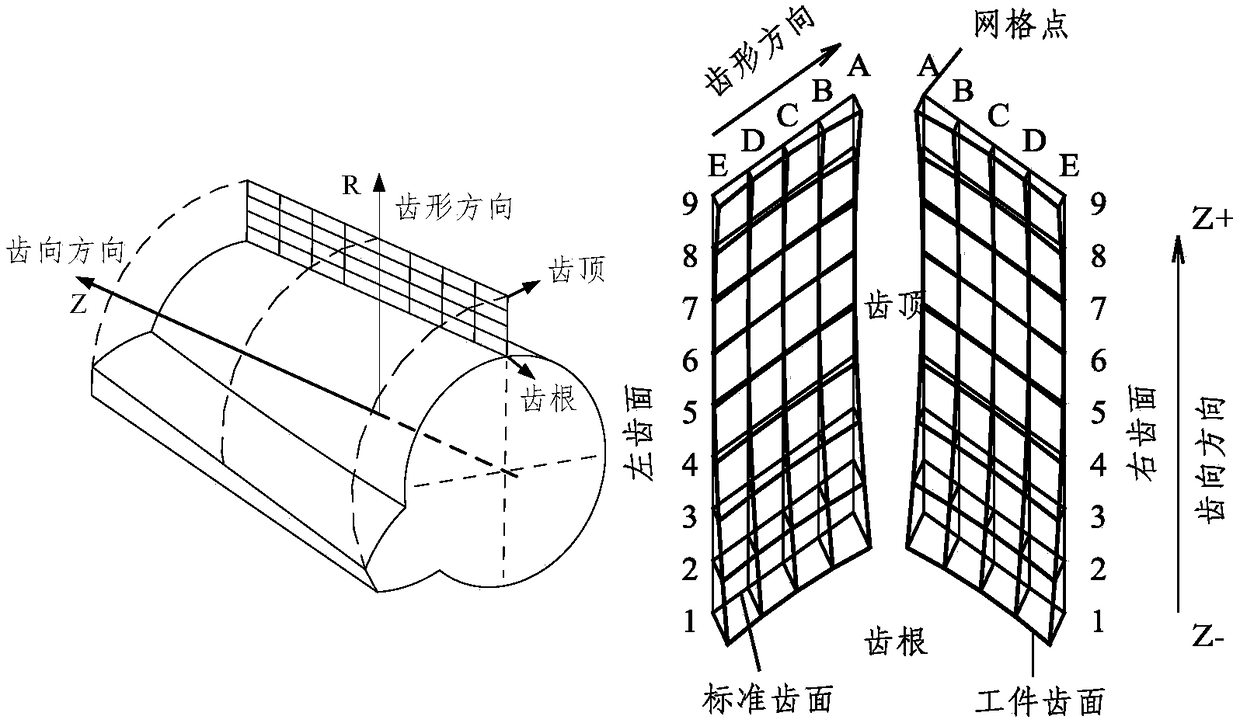

[0038] The number of teeth of the processed gear N g is 73, the normal modulus m n 2.25mm, normal pressure angle α n 20 degrees, tooth width b g 50mm, helix angle β g is 33 degrees, and the direction is right-handed; for the modification amount of the processed gear, see Figure 4 Shown in S5.

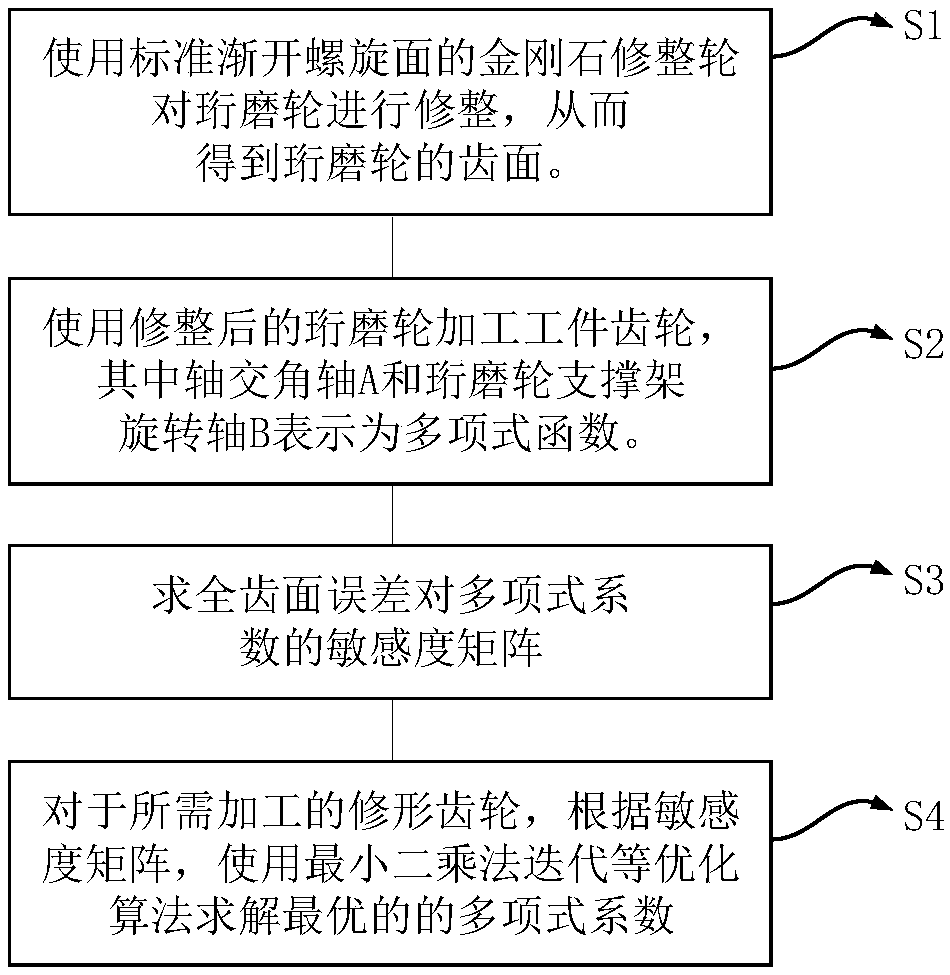

[0039] The specific operation steps of full tooth surface modification of internal tooth power honing are as follows:

[0040] (1) Dressing of honing wheel tooth surface

[0041] according to figure 2 In step S1, use a standard involute helical diamond dressing wheel to dress the honing wheel. The linkage relationship between the rotary axis of the diamond dressing wheel and the rotary axis C1 of the honing wheel is:

[0042]

[0043] Where: φ h is the rotation angle of the honing wheel, in rad; φ d is the diamond dressing wheel rotation angle, in rad. Complete the trimming of the honing wheel tooth surface;

[0044] (2) Establish a mathematical model of the honing proc...

Embodiment 2

[0061] The number of teeth of the processed gear N g is 50, the normal modulus m n 2.25mm, normal pressure angle α n 20 degrees, tooth width b g 50mm, helix angle β g is 33 degrees, and the direction is right-handed; for the modification amount of the processed gear, see Figure 5 Shown in S7, it is the same as the amount of modification in Example 1.

[0062] The specific operation steps of full tooth surface modification of internal tooth power honing are as follows:

[0063] (1) Dressing of honing wheel tooth surface

[0064] according to figure 2 In step S1, use a standard involute helical diamond dressing wheel to dress the honing wheel. The linkage relationship between the rotary axis of the diamond dressing wheel and the rotary axis C1 of the honing wheel is:

[0065]

[0066] Where: φ h is the rotation angle of the honing wheel, in rad; φ d is the diamond dressing wheel rotation angle, in rad.

[0067] (2) Establish a mathematical model of the honing pro...

Embodiment 3

[0084] The number of teeth of the processed gear N g is 50, the normal modulus m n 2.25mm, normal pressure angle α n 20 degrees, tooth width b g 50mm, helix angle β g is 33 degrees, and the direction is right-handed, and the parameters of the processed gear are the same as in embodiment 2; the modification amount of the processed gear is shown in Image 6 Shown in S9.

[0085] The specific operation steps of full tooth surface modification of internal tooth power honing are as follows:

[0086] (1) Dressing of honing wheel tooth surface

[0087] according to figure 2 In step S1, use a standard involute helical diamond dressing wheel to dress the honing wheel. The linkage relationship between the rotary axis of the diamond dressing wheel and the rotary axis C1 of the honing wheel is:

[0088]

[0089] Where: φ h is the rotation angle of the honing wheel, in rad; φ d is the diamond dressing wheel rotation angle, in rad.

[0090] (2) Establish a mathematical model ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tooth width | aaaaa | aaaaa |

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com