Check valve assembly detection line

An assembly detection and one-way valve technology, applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve the problems that are not conducive to improving the overall manufacturing level of assembly process equipment, high labor intensity, difficult to control quality, etc., to achieve assembly quality And high detection efficiency, improve the overall manufacturing level, reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0056] Example.

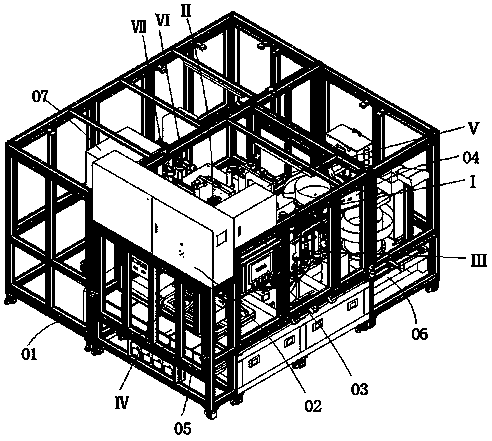

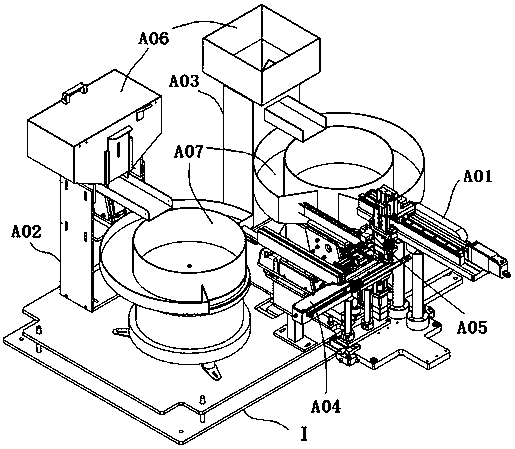

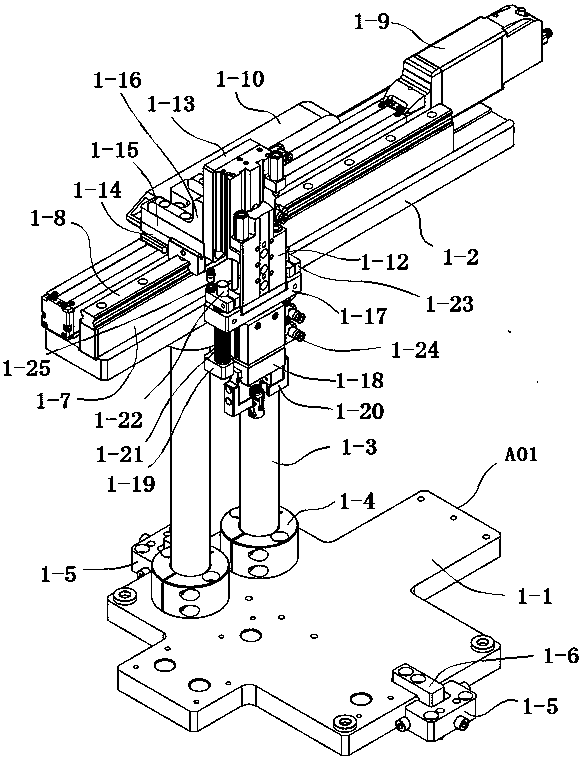

[0057] see Figure 1 to Figure 26 , the one-way valve assembly detection line in this embodiment includes shell feeding mechanism I, steel ball filter assembly mechanism II, turntable tooling assembly III, spring feeding mechanism V, spring retrieving mechanism VI, spring conveying assembly VII, and flip testing mechanism Ⅳ. Frame main body 01, electric control cabinet 02, touch screen 03, display 04, material box 05, base 06 and spring machine 07, electric control cabinet 02, touch screen 03, display 04 and material box 05 are all set on the frame main body 01, Both the base 06 and the spring machine 07 are arranged in the frame main body 01 .

[0058] The shell feeding mechanism I, spring retri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com