3D curved glass laminating device and method

A technology of curved glass and laminating equipment, which is applied in packaging, packaging under vacuum/special atmosphere, etc., can solve the problems that 3D glass physics cannot do, difficult curved glass lamination and coverage, and inability to apply curved surface products, etc., to achieve lamination The effect of stable quality, fast bonding speed and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

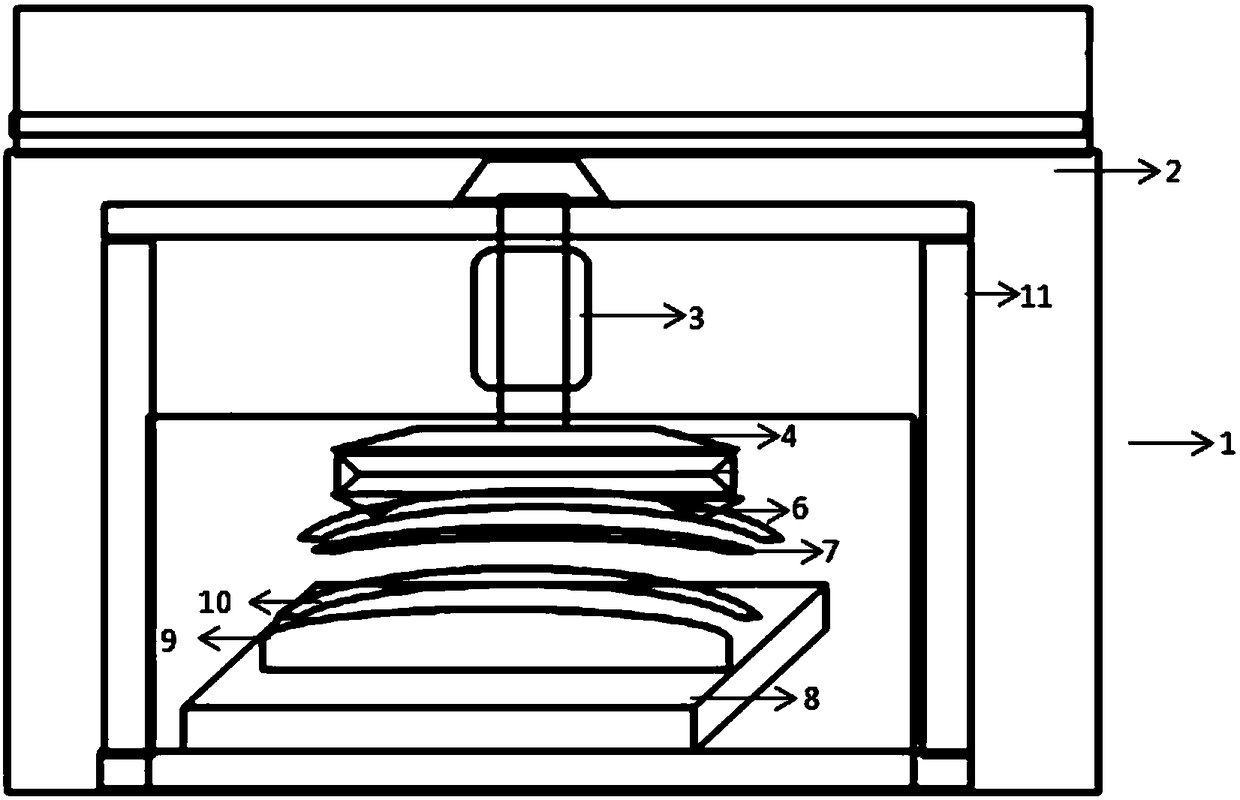

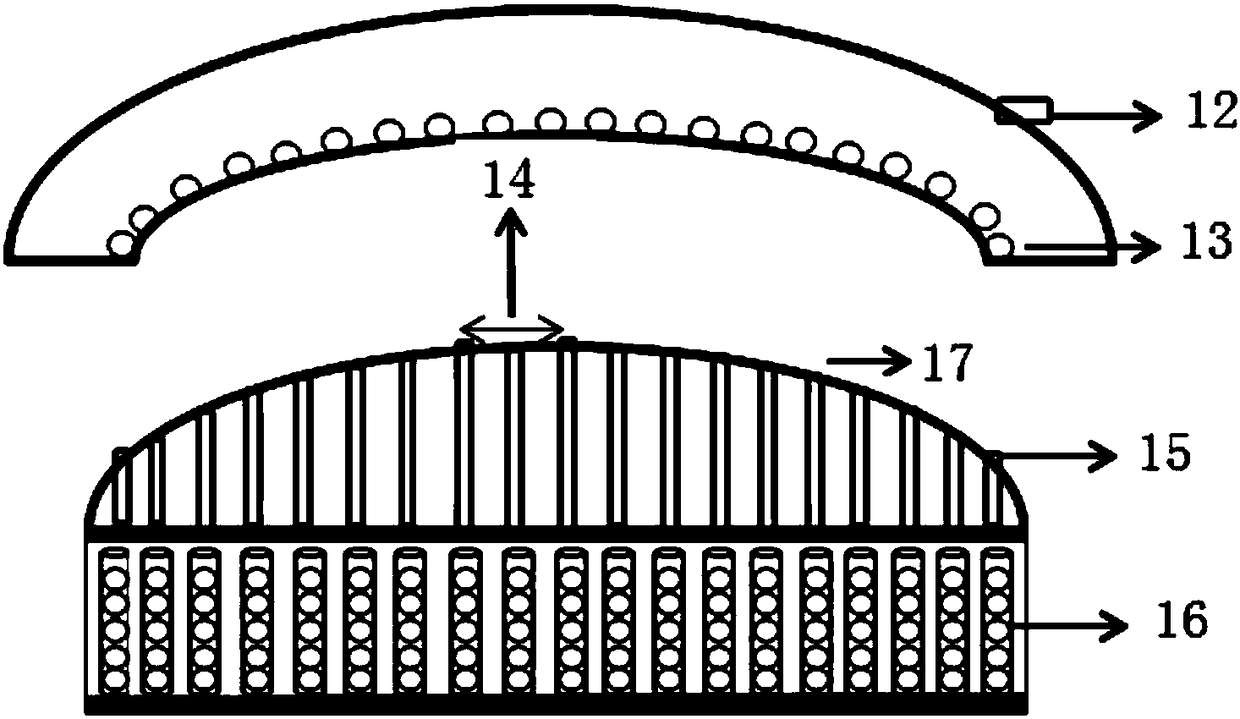

[0023] refer to figure 1 , 3D curved glass laminating equipment 1 includes a casing 2, an upper lamination module 6, a lower lamination module 9 and a heating module 4, the upper lamination module 6 fixes a mobile phone LCD screen 7, and the lower lamination module 9 The curved glass 10 is fixed on the upper side, and the lower pressing module 9 can be installed on the fixed platform 8 . Through the pressing of the upper pressing module 6 and the lower pressing module 9 and the heating of the heating module 4, the mobile phone liquid crystal screen 7 and the curved glass 10 can be bonded together. In the figure, the upper lamination module 6, the mobile phone LCD screen 7, the lower lamination module 9, and the curved glass 10 are only schematic repre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com