Capsule dust removing and bottling device

A capsule and bottling technology, applied in the directions of packaging, packaging protection, transportation and packaging, can solve the problems of affecting the hygienic quality of capsules, high labor intensity, secondary pollution of capsules, etc., achieving a high degree of automation, reducing labor intensity, The effect of high precision of dispensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

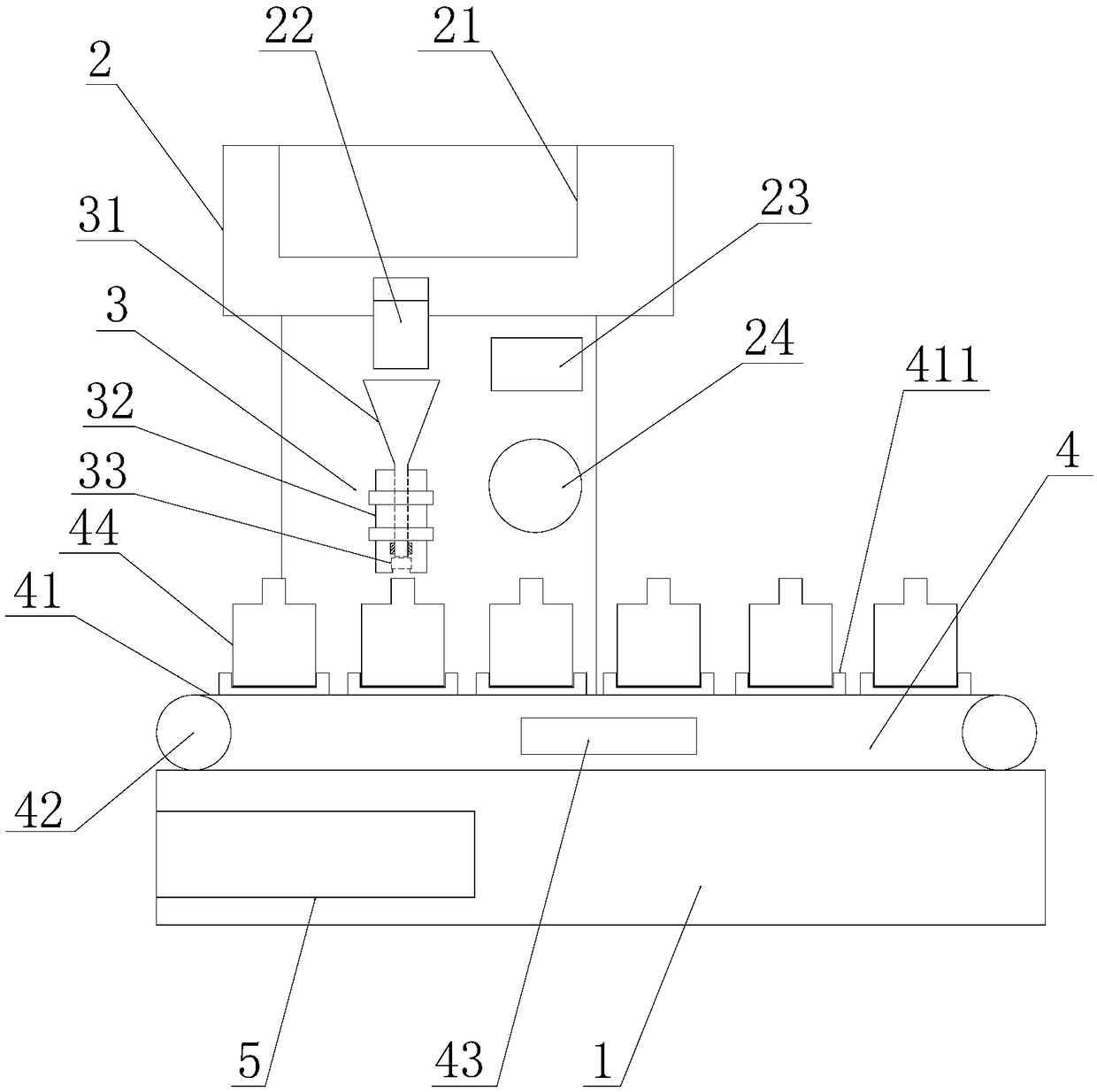

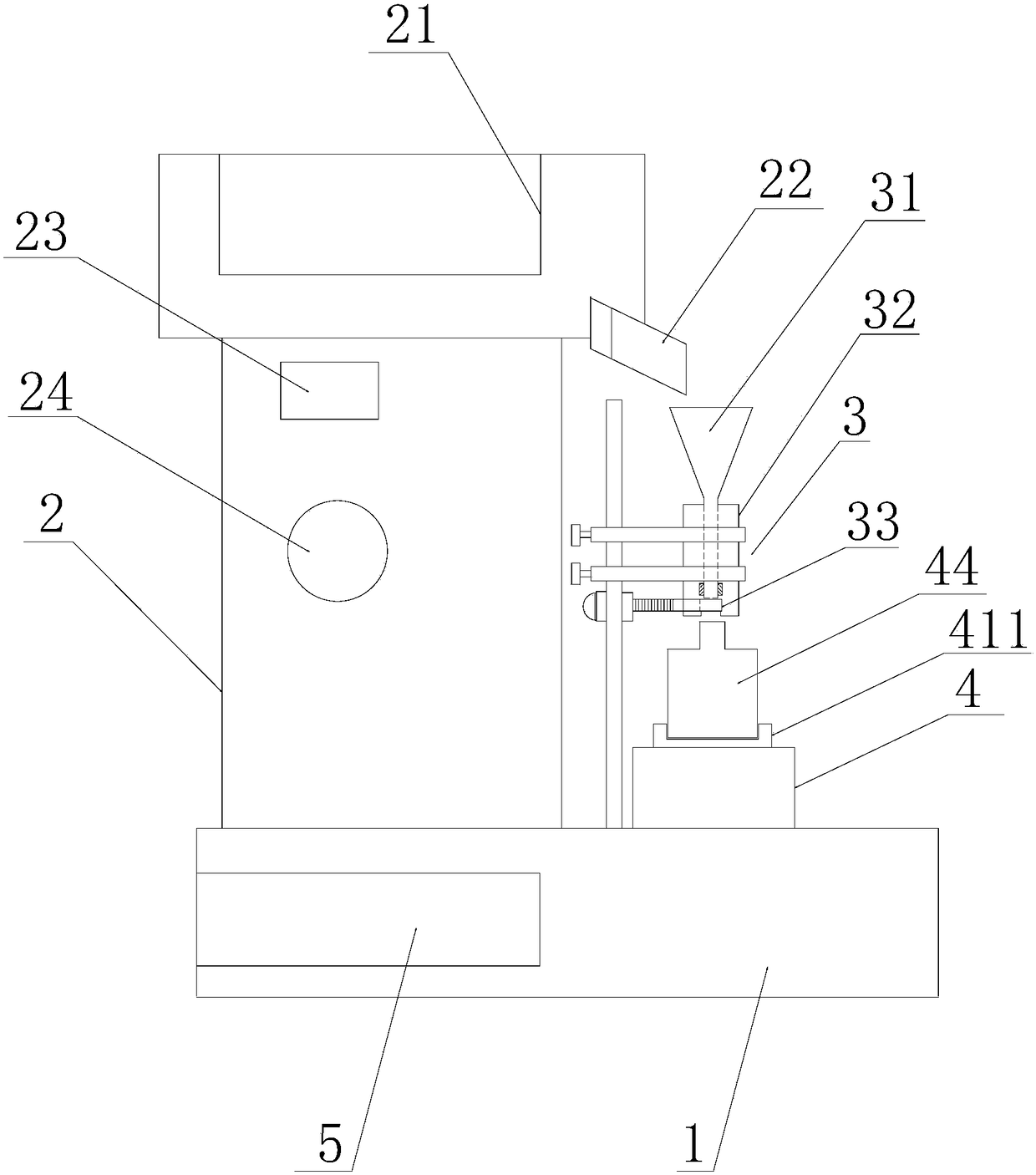

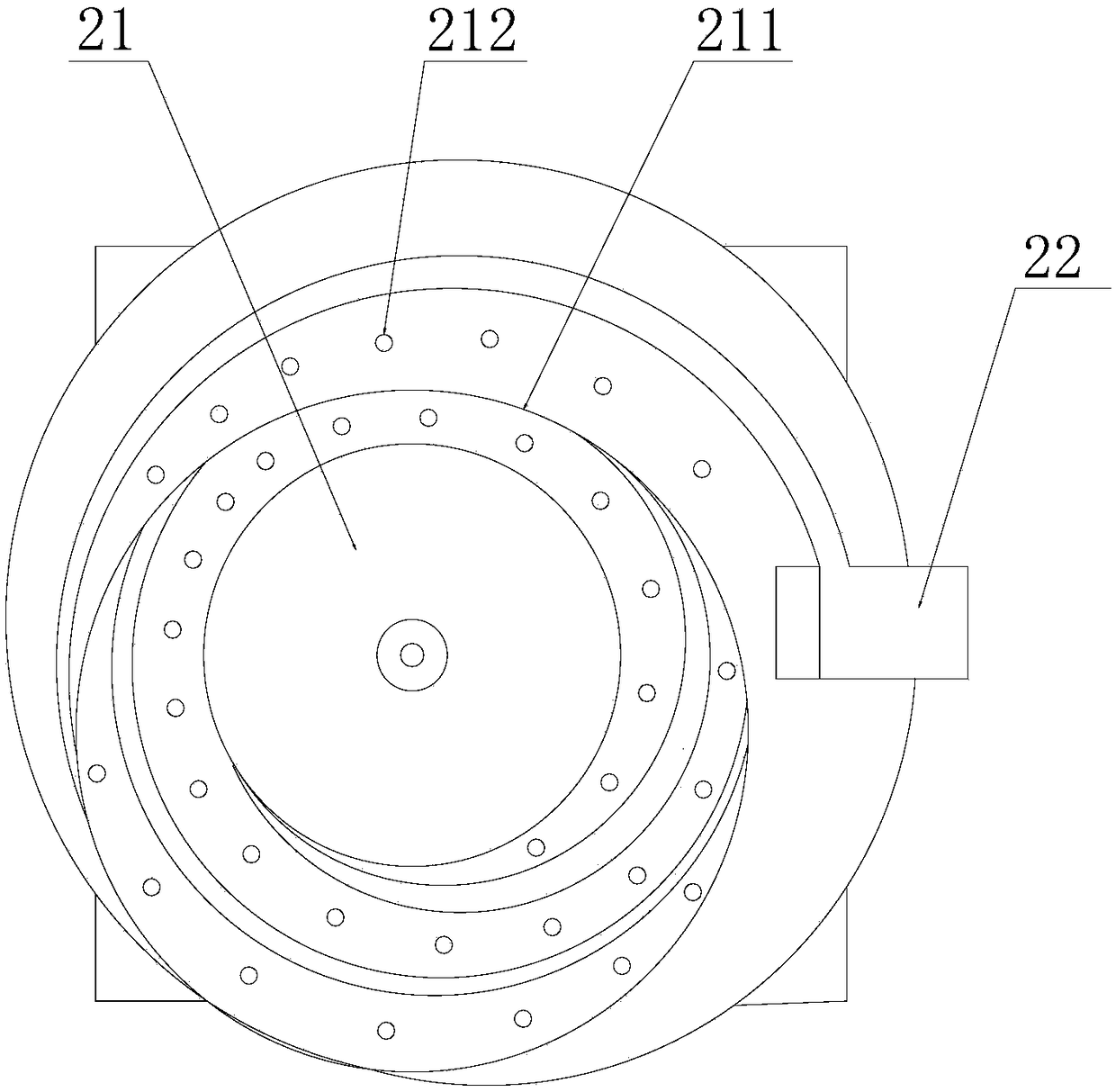

[0016] refer to figure 1 , figure 2 , image 3 and Figure 4 , a capsule dedusting and bottling device of the present invention, comprising a base 1, a dedusting mechanism 2, a grain counting mechanism 3, a transmission mechanism 4 and a control mechanism 5, the dedusting mechanism 2, the grain counting mechanism 3, and the transmission mechanism 4 are installed and fixed on On the base 1, a control mechanism 5 is also provided on the base 1. The dust removal mechanism 2, the grain counting mechanism 3, and the transmission mechanism 4 are connected to the control mechanism 5. The dust removal mechanism 2 includes a vibrating plate 21 and a feeding plate 22, the wall of the vibrating plate 21 is provided with a dust removal hole 212, the vibrating plate 21 is connected to the feeding plate 22, and the vibrating plate 21 and the feeding plate 22 cooperate with each other to transport the capsules to the grain counting mechanism 3. The numbering mechanism 3 includes a feed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com