An extension structure suitable for adjusting the position of the center of gravity of tenon-connected rotor blades

A rotor blade and center-of-gravity position technology, applied in the direction of blade support elements, machines/engines, mechanical equipment, etc., can solve problems such as uneven contact stress and bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention, and the present invention is not limited to the following examples.

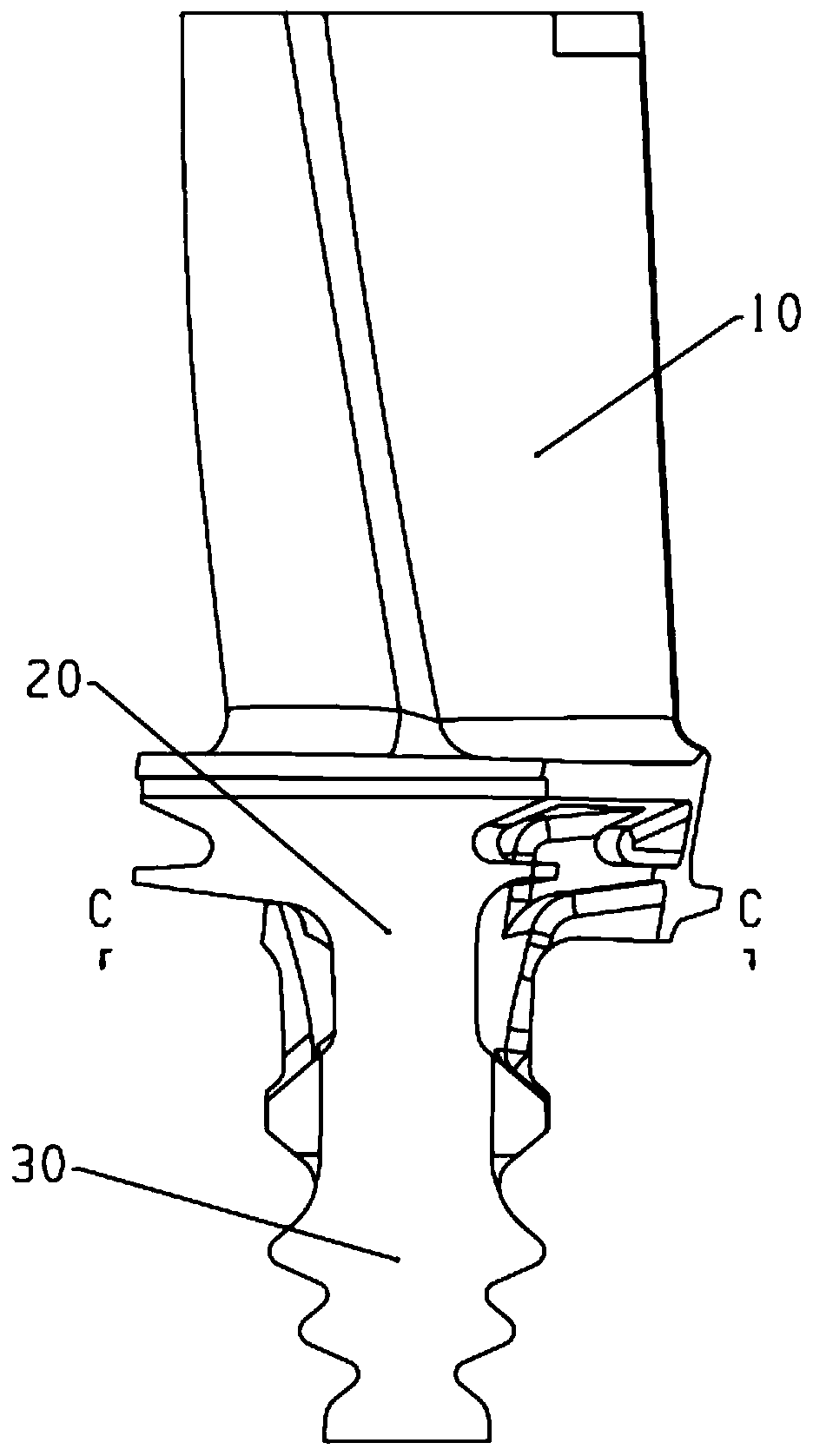

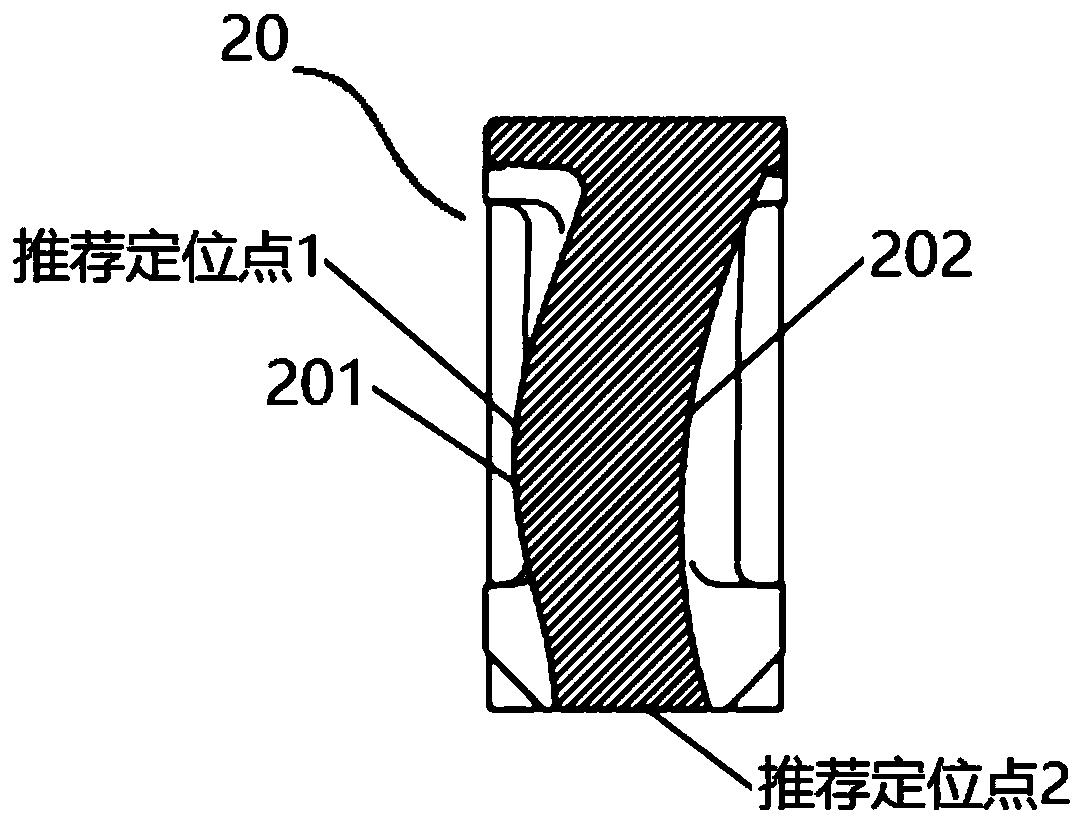

[0022] figure 1 It is a schematic diagram of the structure of the tenon-jointed rotor blades in a certain type of turbofan engine adopting the root extension structure of the present invention. Such as figure 1 As shown, the rotor blade is sequentially divided into three parts: the blade body section 10 , the root extension section 20 and the tenon section 30 from top to bottom. Among them, such as figure 2 As shown, the leaf back side 201 and the leaf basin side 202 of the root extension section 20 adopt an asymmetrical profile line (see the C-C sectional view), and use the asymmetrical line change law to realize the adjustment of the center of gravity of the blade. The two sides of the root section 20 can also be shaped by the wing / bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com