Intelligent monitoring system for sludge drying

A sludge drying and intelligent monitoring technology, which is applied in the general control system, control/regulation system, measuring device, etc., can solve the problems of difficult sludge drying change process, lack of continuity and real-time monitoring, etc., to achieve convenient The effect of field wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further described in conjunction with the following examples.

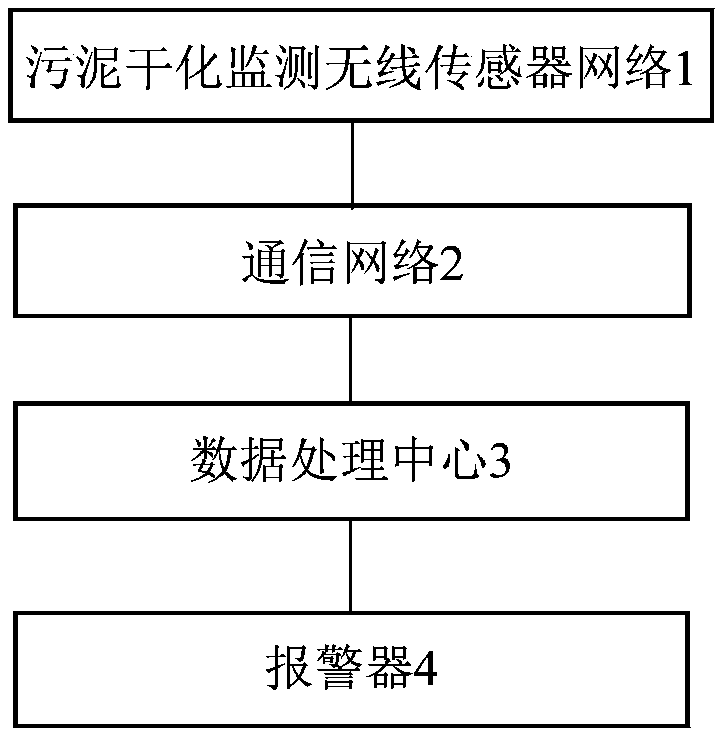

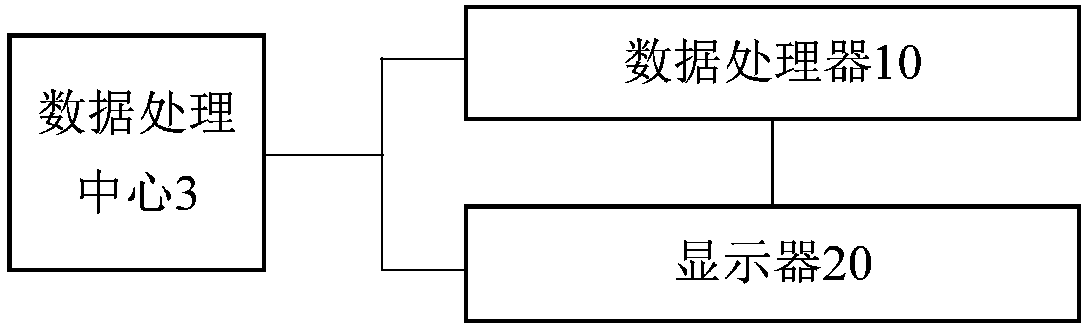

[0016] see figure 1 The sludge drying intelligent monitoring system provided in this embodiment includes a sludge drying monitoring wireless sensor network 1, a communication network 2 and a data processing center 3, and the sludge drying monitoring wireless sensor network 1 communicates with data processing through the communication network 2 The centers 3 are connected, and the sludge drying monitoring wireless sensor network 1 is composed of sensor nodes and sink nodes connected through a wireless sensor network.

[0017] Wherein, the communication network 2 is a satellite communication network, Ethernet, field bus network or radio station.

[0018] Among them, the sensor node monitors and perceives the sludge drying monitoring area, and sends the obtained sludge drying parameters to the sink node. The sensor node includes a sensor, a signal conditioning circuit, a microprocess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com