Wireless ultrasonic detection device

An ultrasonic testing and wireless technology, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids and optical testing for flaws/defects, etc. It can solve problems that affect the efficiency and progress of inspection work, and achieve convenient review work, reduced labor, and convenient detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

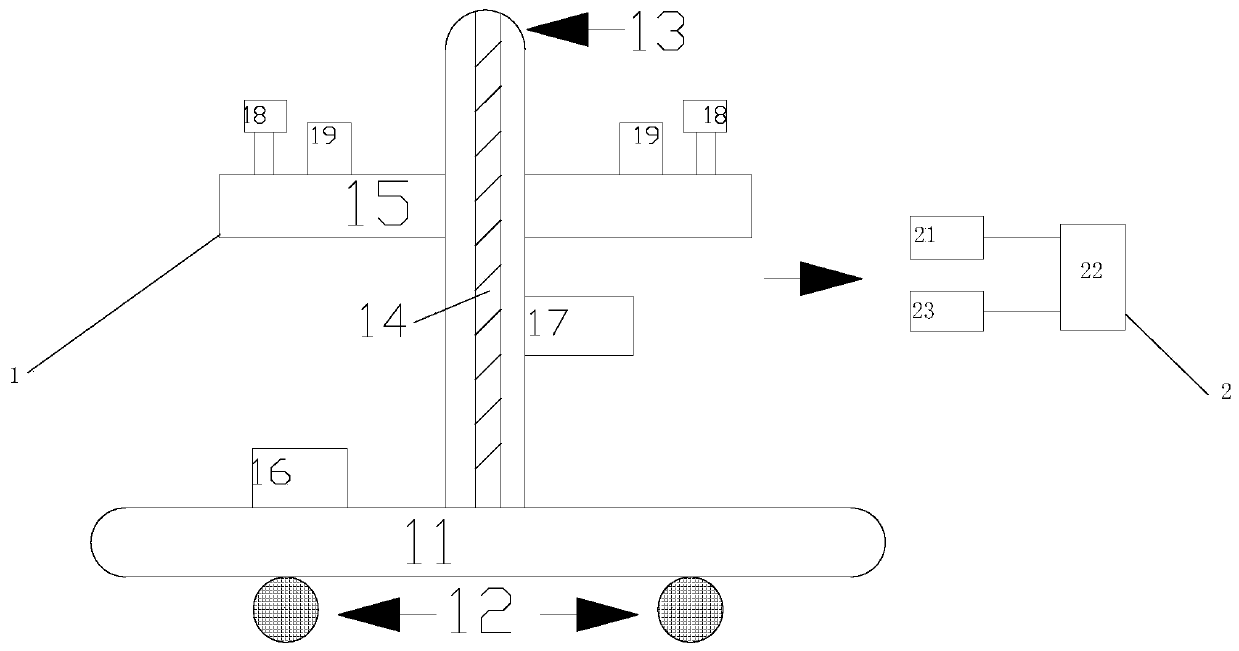

[0017] Such as figure 1 As shown, the present invention is a wireless ultrasonic detection device, including an operating system terminal 1 and a control terminal 2, the operating system terminal 1 and the control terminal 2 are connected, and the operating system terminal 1 includes a circumferential scanning shaft 11, a magnetic wheel 12, a shaft To scan axis 13, screw mandrel 14, frock 15, first miniature camera 16, second miniature camera 17 and ultrasonic probe 18, be provided with magnetic wheel 12 under circumferential scanning axis 11, circumferential scanning axis 11 and shaft Connect to the scanning shaft 13, the axial scanning shaft 13 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com