Device for increasing the exhaust velocity of a pneumatic regulating valve

A technology of exhaust speed and regulating valve, which is applied in the direction of valve operation/release device, valve device, control valve and air release valve, etc., which can solve the problems of reducing exhaust speed, unfavorable exhaust air flow, and abnormal exhaust air flow. Best etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

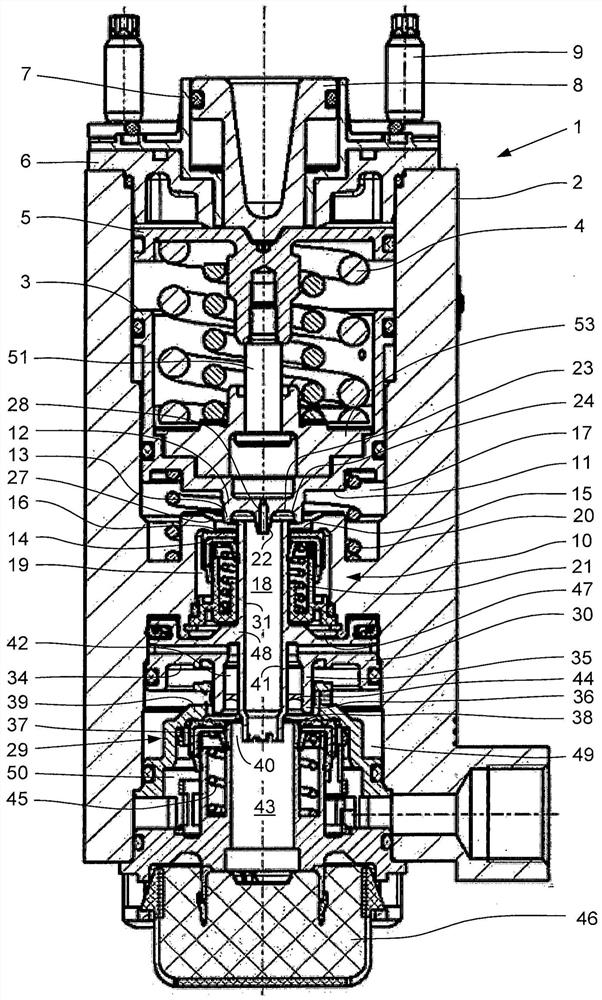

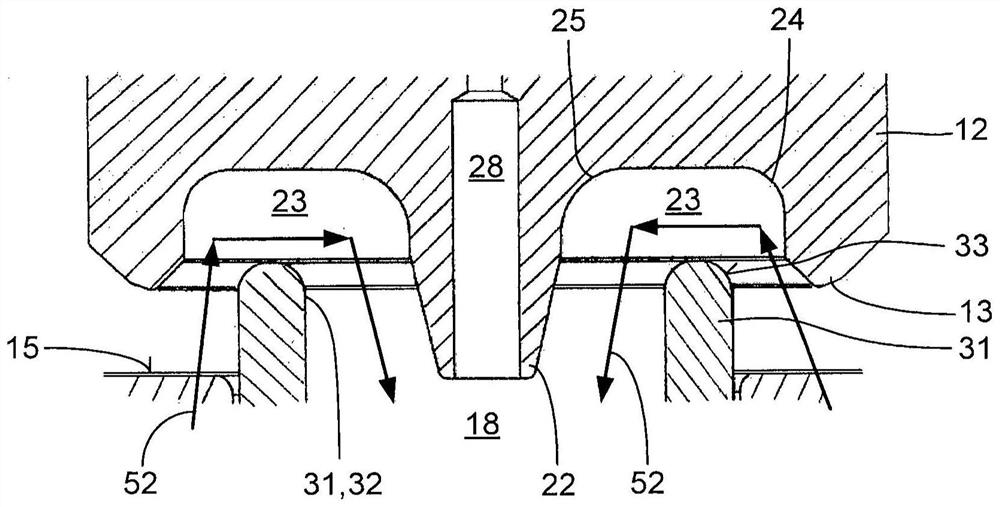

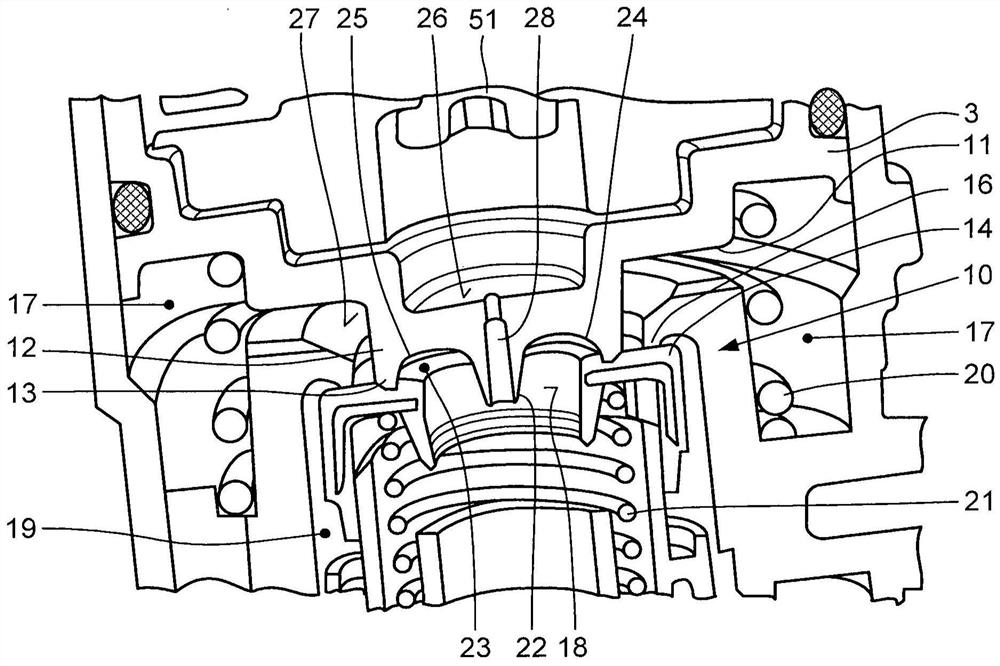

[0018] A regulating valve 1 designed as a brake value indicator for a dual-circuit brake system of a motor vehicle has a housing 2 in which a first valve piston 3 is guided in a sealing manner. The plunger 8 is axially guided on the housing cover 6 in a hollow-cylindrical guide 7 . The housing cover 6 together with the guide 7 is screwed onto the housing 2 by means of fastening screws 9 . Arranged below the underside 11 of the first valve piston 3 is a first valve system 10 comprising a cylindrical projection 12 and an annular sealing seat 13 arranged on the free end of the projection. The first valve piston 3 of the first valve piston 3, the annular first plate valve 14 with the radial sealing surface 15, and the annular sealing seat 13 having a diameter larger than that on the cylindrical protrusion 12 of the first valve piston 3 A large, immovable annular first seal seat 16.

[0019] The cylindrical protrusion 12 on the first valve piston 3 and the immovable, annular firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com