System and method for representing a cause and effect matrix as a set of numerical representations

A numerical representation and aggregation technology, applied in general control systems, control/regulation systems, test/monitoring control systems, etc., can solve the problems of the size of the limited matrix definition, injury of factory personnel, and error-proneness, so as to reduce the complexity , logical and easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

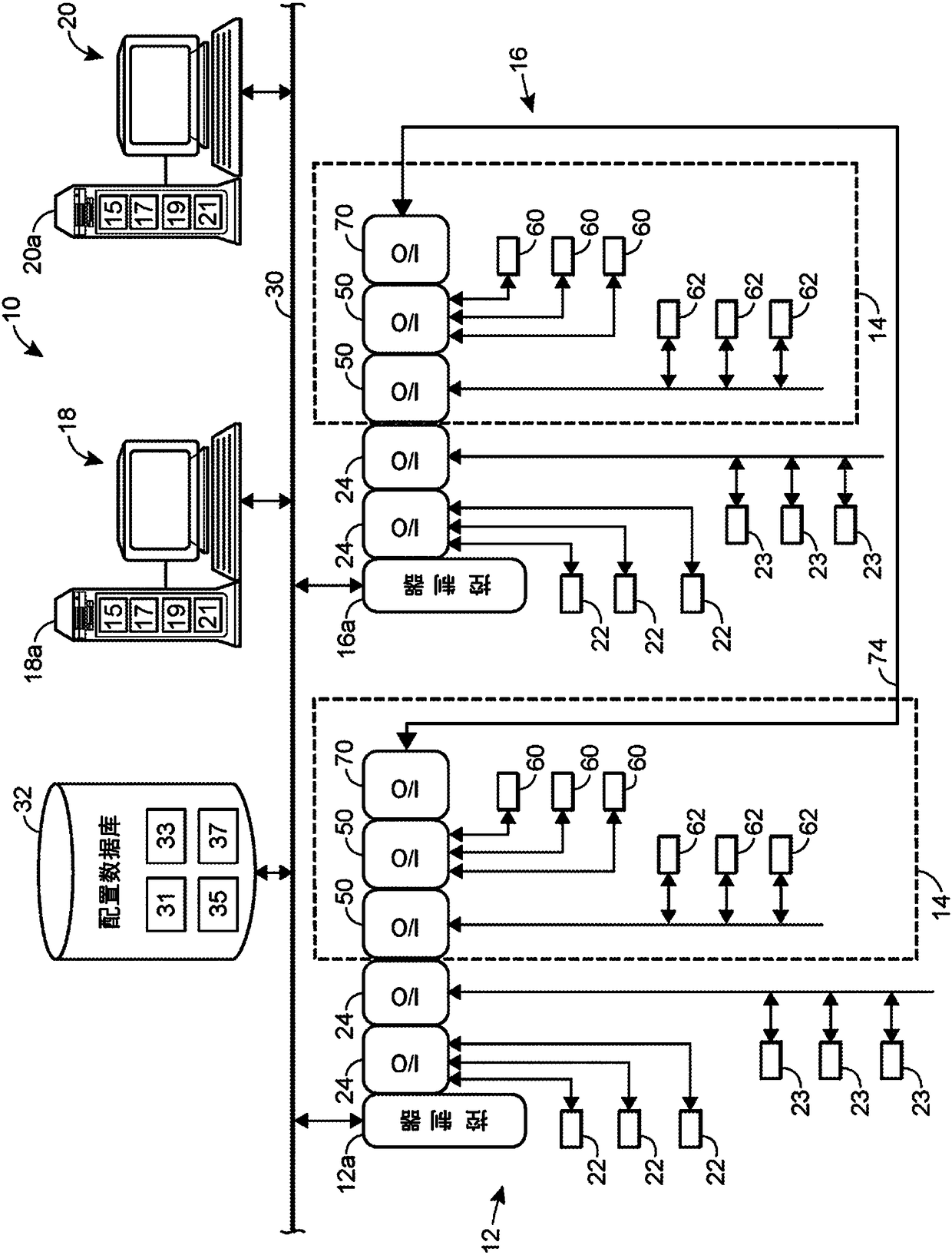

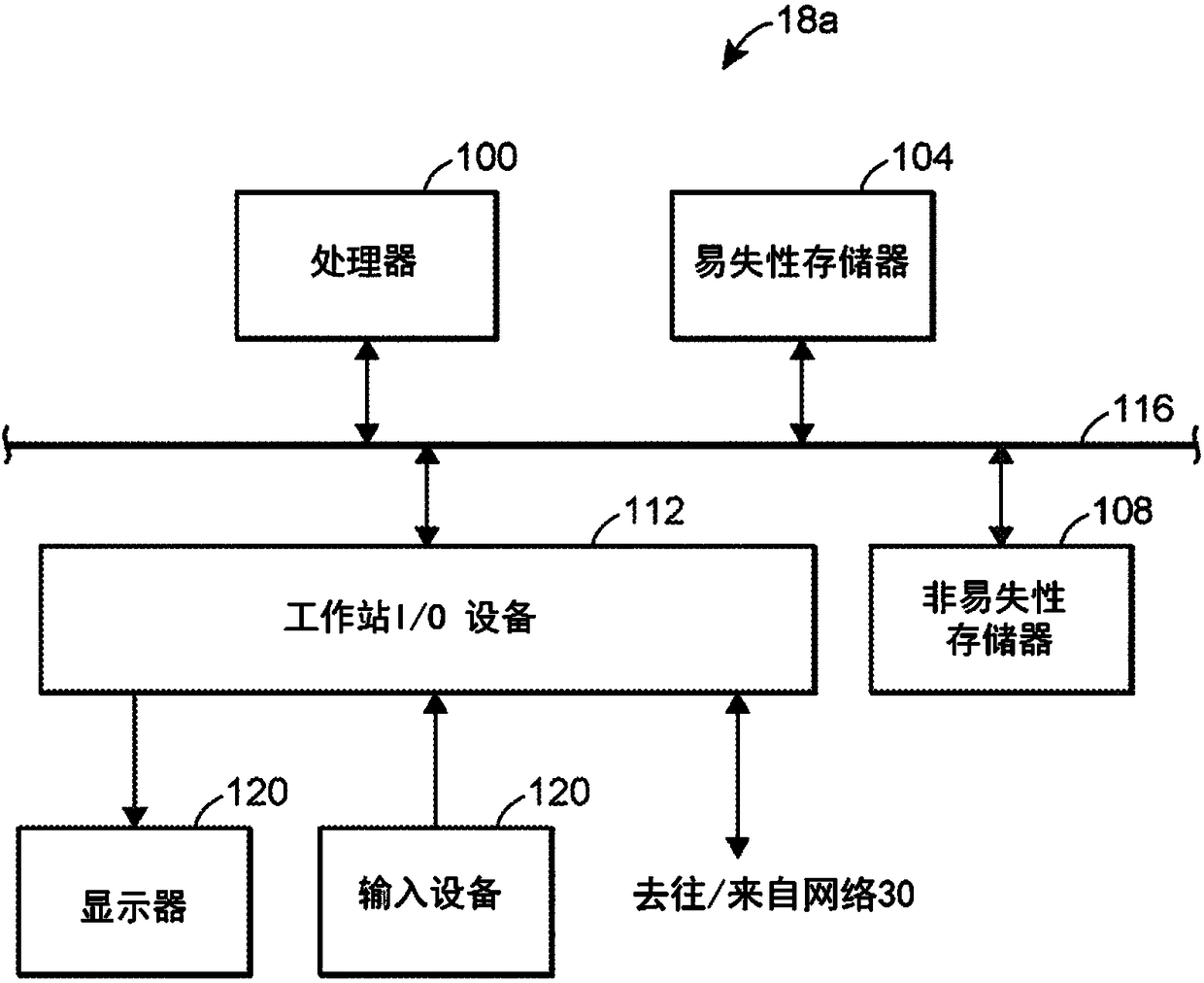

[0033] figure 1 is a block diagram of an exemplary process plant 10 including one or more nodes 12 , 16 , 18 and 20 . exist figure 1 In the exemplary process plant 10, each of the nodes 12 and 16 includes a process controller 12a, 16a connected to one or more field devices 22 via an input / output (I / O) device 24 and 23, the input / output (I / O) device 24 may be, for example, a Foundation Fieldbus (Fieldbus) interface, a HART interface, and the like. Controllers 12a and 16a are also coupled to one or more host or operator workstations 18a and 20a in nodes 18 and 20 via a network 30, which may include, for example, a bus, a wired local area network (LAN) such as an Ethernet LAN, a wireless LAN , a wide area network (WAN), an intranet, or the like. While the controller nodes 12, 16 and their associated I / O devices 24 and field devices 22, 23 are typically located within and distributed throughout the sometimes harsh plant environment, the operator workstation nodes 18 and 20 Typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com