Split type electric pressure cooker

An electric pressure cooker and split-type technology, which is applied to pressure cookers, cooking utensils, household utensils, etc., can solve problems such as the inability of the lid part and the pot body to transmit current and electrical signals, and hand steam burns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

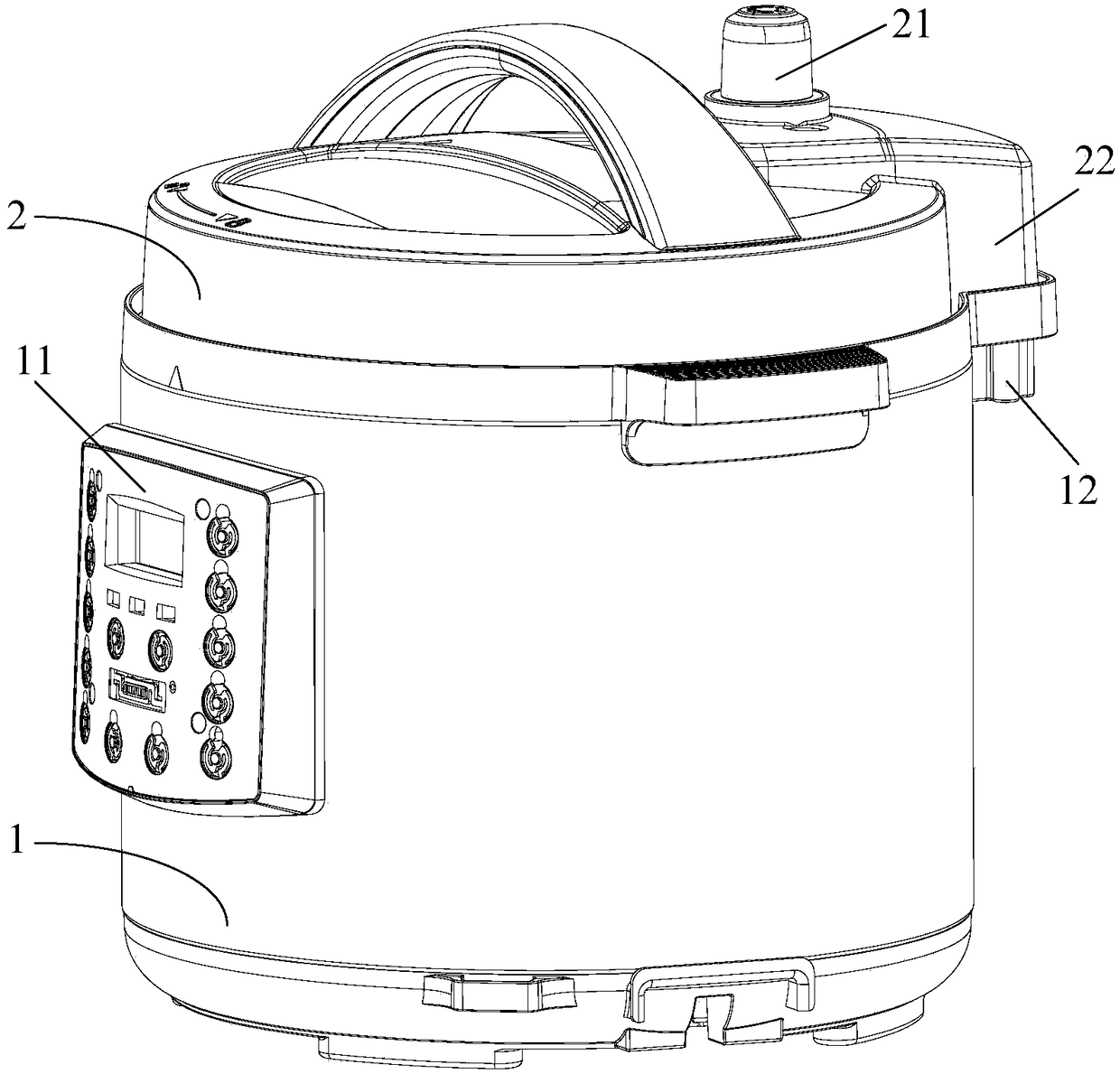

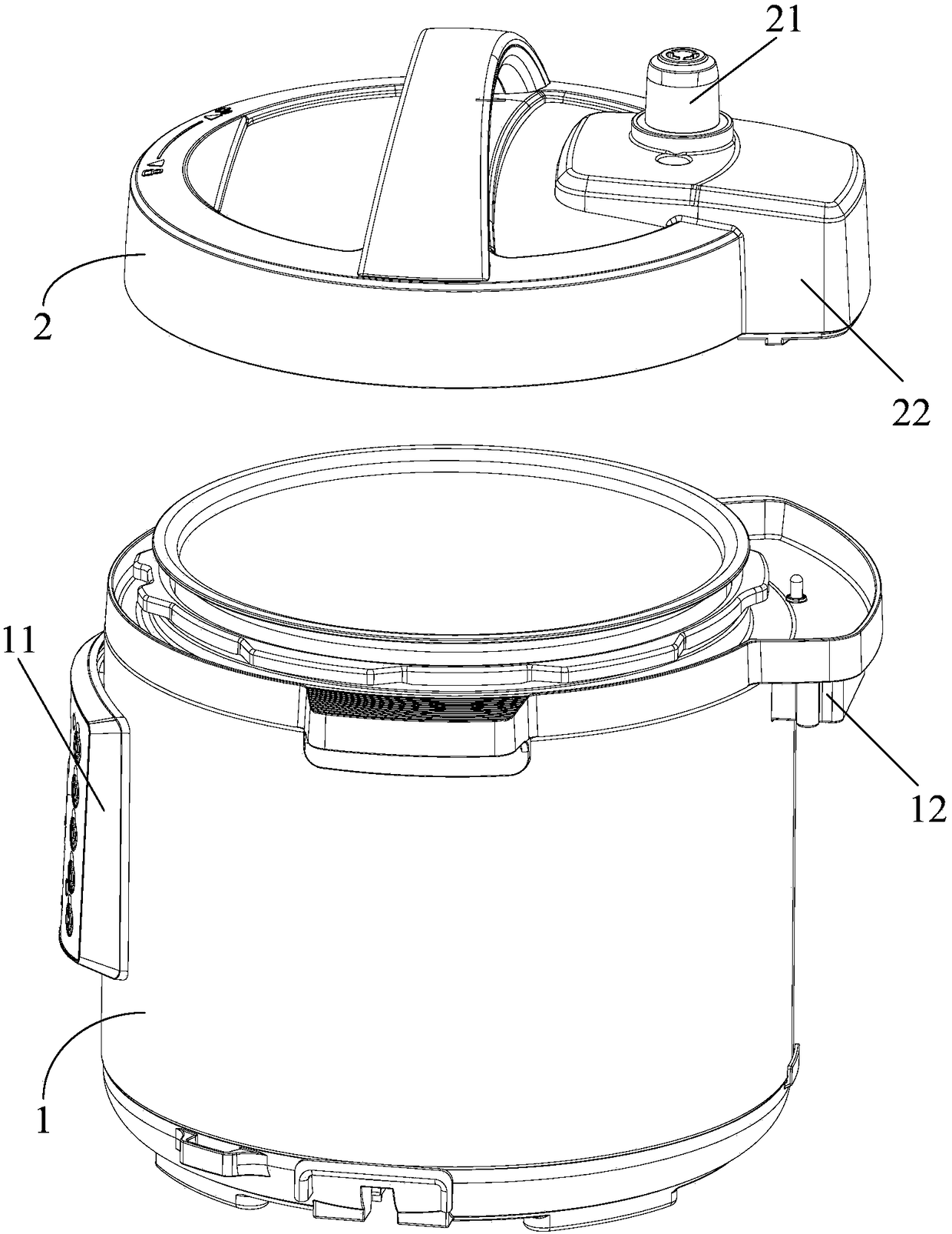

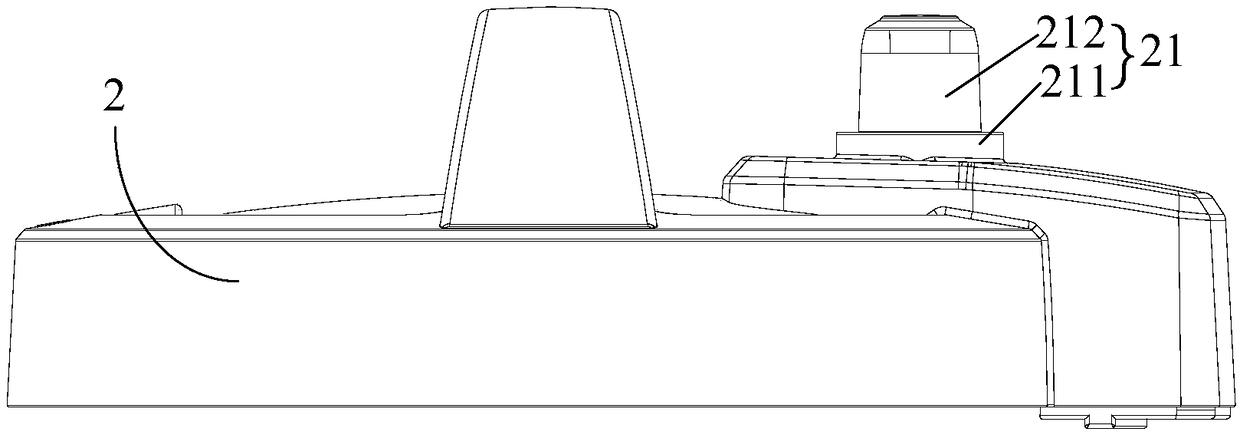

[0047] Such as Figure 1 to Figure 9 As shown, the split-type electric pressure cooker includes: a pot body 1, a pot cover 2, an electric exhaust valve 21, an electric energy transmission device 12 and an electric energy receiving device 22, and a control panel 11 is installed on the front of the pot body 1. A main control board (ie a controller) is installed, and an exhaust switch is arranged on the control panel 11, and the main control board is electrically connected with the exhaust switch and the power supply device of the split electric pressure cooker. Electric control exhaust valve 21 comprises valve seat 211 and valve cover 212, and valve seat 211 is fixedly installed in the exhaust valve installation groove 210 on the pot cover 2, and valve cover 212 can be installed on the valve seat 211 movably, and valve cover 212 A magnet 2121 is fixedly installed inside, and an electromagnet is fixedly installed inside the valve seat 211 . The power transmission device 12 inclu...

Embodiment 2

[0052] Split type electric pressure cooker includes: pot body, pot cover, electric control exhaust valve, electric energy transmission device and electric energy receiving device. An exhaust switch is arranged on the control panel, and the main control panel is electrically connected with the exhaust switch and the power supply device of the split electric pressure cooker. The electric control exhaust valve includes a valve seat and a valve cover. The valve seat is fixedly installed in the exhaust valve installation groove on the pot cover. The valve cover can be movably installed on the valve seat. An electromagnet is fixedly installed. The power transmission device includes: a first cylindrical coil, a first PCB control board (i.e. a secondary controller) and a transmission device mounting seat, the first cylindrical coil and the first PCB control board are fixedly installed on the transmission device mounting seat, and the pot body There is a transmission device installati...

Embodiment 3

[0056] Split type electric pressure cooker includes: pot body, pot cover, electric control exhaust valve, electric energy transmission device and electric energy receiving device. An exhaust switch is arranged on the control panel, and the main control panel is electrically connected with the exhaust switch and the power supply device of the split electric pressure cooker. The electric control exhaust valve includes a valve seat and a valve cover. The valve seat is fixedly installed in the exhaust valve installation groove on the pot cover. The valve cover can be movably installed on the valve seat. An electromagnet is fixedly installed.

[0057] Wherein, the power transmission device includes a power socket, and the power socket is electrically connected to the main control board. The power receiving device includes a power plug and a PCB control board with a rectification circuit (that is, a rectification device). The first power plug is electrically connected to the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com