Fan master control signal system

A signal system and fan technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve the problems of digital output module voltage instability, long operating life of fan units, etc., to shorten the power supply distance, eliminate voltage drop or not The effect of stabilizing the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

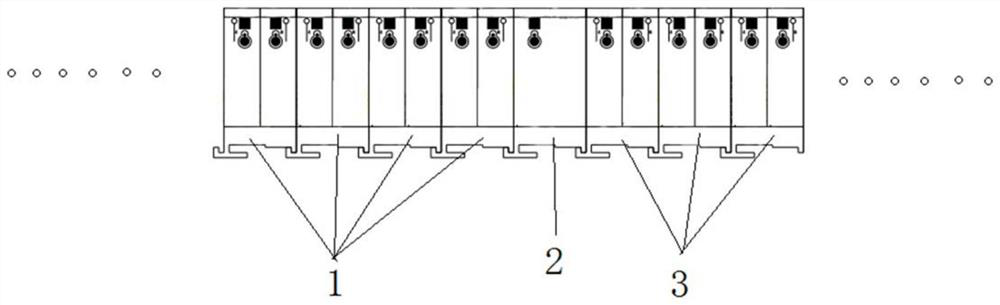

[0019] This embodiment provides a fan main control signal system, including a plurality of digital output modules 3, and a first power supply module and a plurality of digital input modules 1 electrically connected in sequence, and also includes a second power supply module 2, a second power supply module 2 A plurality of digital output modules 3 are electrically connected.

[0020] in particular:

[0021] Multiple digital input modules 1 are sequentially arranged and inserted into the slots of the chassis, multiple digital output modules 3 are sequentially arranged and inserted into the slots of the chassis, the first power supply module is located at one end of the multiple digital input modules 1 and inserted into the slots of the chassis, the second The second power supply module 2 is located in the chassis slot between the multiple digital input modules 1 and the multiple digital output modules 3 .

[0022] Digital input module 1 is KL1408 digital input module.

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com