Slab Continuous Casting Stopper Rod Flow Control and Automatic Opening Technology Based on Liquid Level Automatic Control

A technology of automatic liquid level control and automatic pouring, applied in manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of quality defects of slag inclusion in the topping billet, large fluctuation of steel flow size control, etc. The effect of process time elapse, solving unstable state, and improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

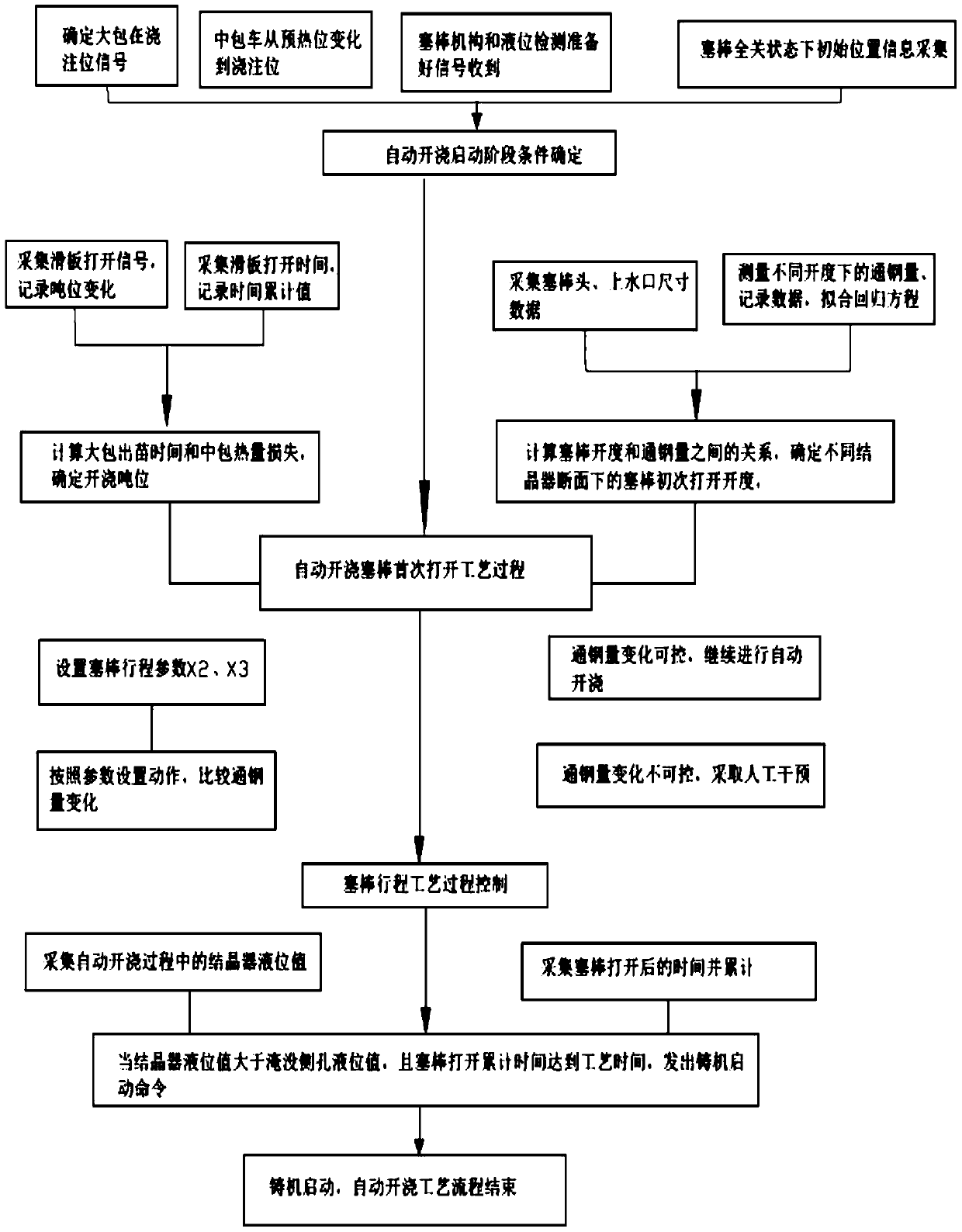

[0058] Embodiment 1: see figure 1 , a slab continuous casting plug rod flow control automatic pouring method based on automatic liquid level control, characterized in that the method comprises the following steps:

[0059] 1 Determination of conditions in the start-up stage of automatic pouring

[0060] 1.1 Collect the parameters of the ladle at the pouring position, and confirm that the signal of the ladle at the pouring position is received;

[0061] 1.2 Collect the information of the tundish car from the preheating position to the pouring position, and confirm that the position information of the new tundish car changes from the preheating position to the pouring position;

[0062] 1.3 Collect the ready signal of the stopper control mechanism on the tundish car and the ready signal of the liquid level detection device;

[0063] 1.4 Collect the initial position information of the single-flow stopper rod when it is fully closed;

[0064] 1.5 When the above conditions 1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com