Upper die stamping electrically-controlled numerical adjusting device of ultra-large-size powder press

A digital adjustment and super-large technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of adjustment accuracy, difficult maintenance and replacement, high sealing requirements, etc., and achieve the effects of small adjustment resistance, reduced labor intensity, and small frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

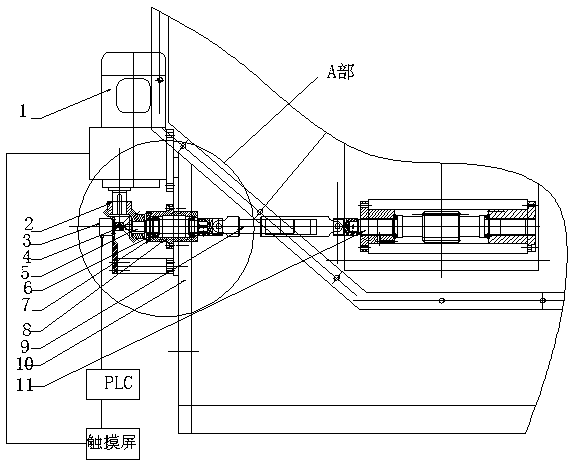

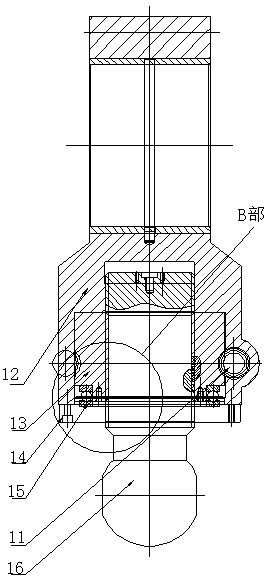

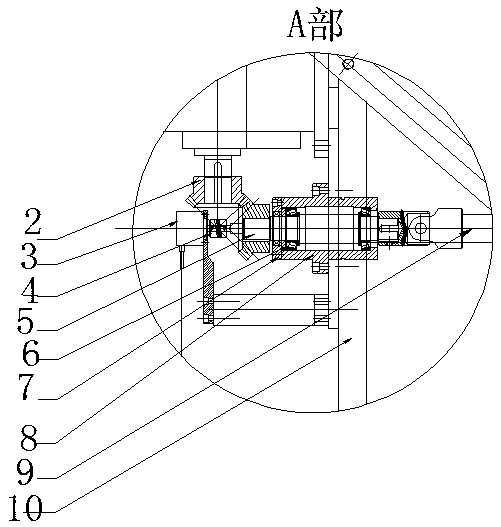

[0020] The present invention includes an upstroke adjustment motor 1, and the upstroke adjustment motor 1 drives the adjustment transmission shaft 5 to rotate through a gear set;

[0021] The transmission of the adjustment transmission shaft 5 is divided into two sets, one of which is connected to the telescopic precision universal joint 9, the telescopic precision universal joint 9 drives the rotation of the adjustment worm 11, and the rotation of the adjustment worm 11 drives the rotation of the adjustment worm wheel 13, The adjusting worm gear 13 is connected with the upper connecting rod 12 through a connecting device, and the adjusting worm gear 13 is also threaded with a ball adjustment screw 16, and the ball adjustment screw 16 is connected to the upper sliding column and the upper beam;

[0022] The other said adjusting drive shaft drives the rotary encoder 3 to rotate through the encoding shaft coupling 5 .

[0023] The upstroke adjustment motor 1 drives the adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com