Engine overspeed preventive control system

A technology of engine overspeed and control system, which is applied in the direction of control/regulation system, non-electric variable control, speed/acceleration control, etc. It can solve the problems of engine overspeed damage, reduce system calorific value, etc., and achieve the effect of preventing overspeed damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

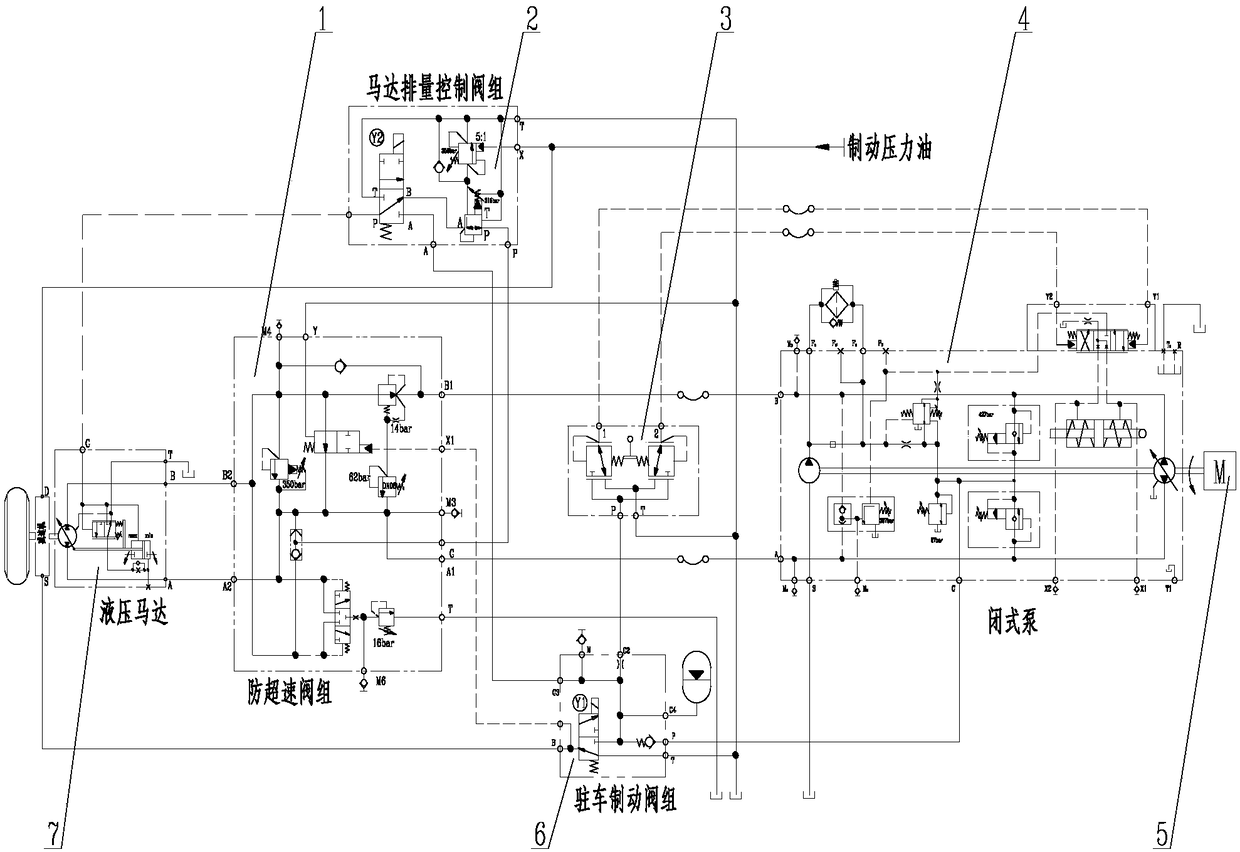

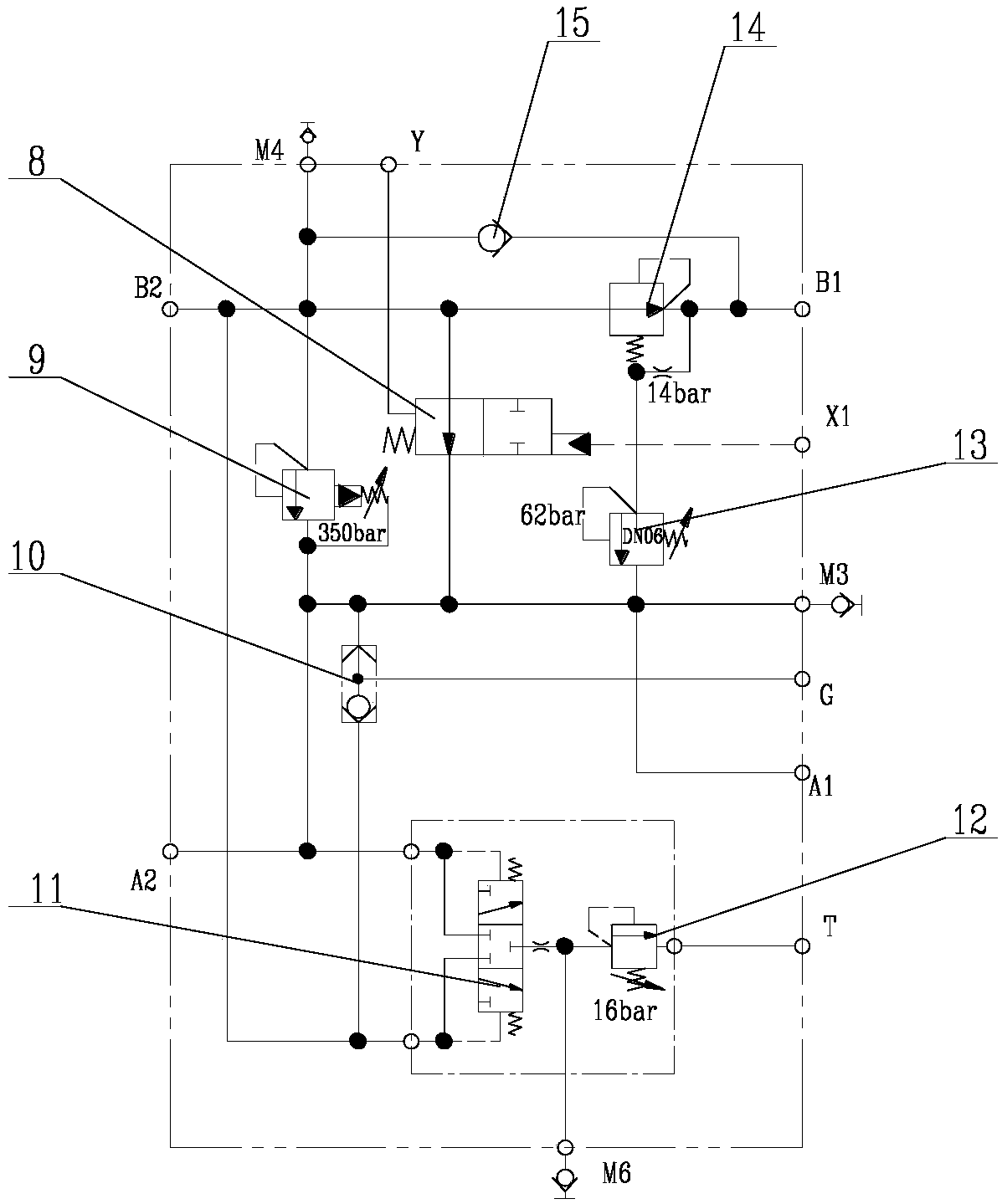

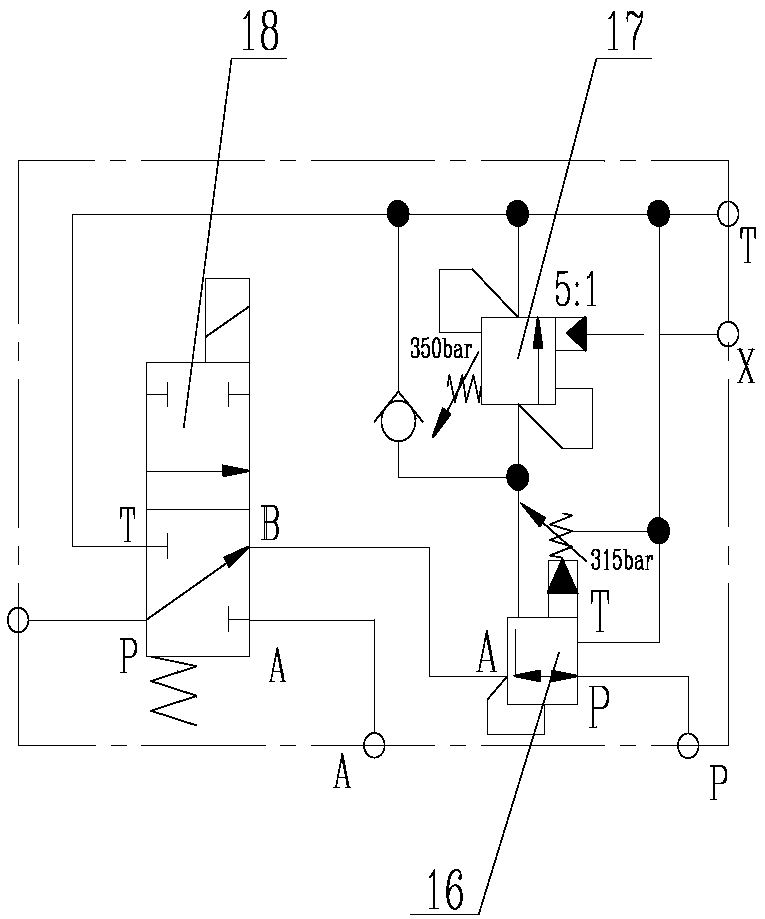

[0030] The embodiment of the present invention provides a control system for preventing engine 5 from overspeeding, please refer to Figure 1 to Figure 3 , the system includes:

[0031] Anti-overspeed valve group 1, the anti-overspeed valve group 1 includes: oil port B2; oil port B1, the oil port B1 and the oil port B2 can be connected inside the anti-overspeed valve group 1; oil port A2; Oil port A1, the oil port A1 and the oil port A2 can communicate with each other inside the anti-overspeed valve group 1;

[0032] Closed plunger pump 4, the oil port B of the closed plunger pump 4 can be communicated with the oil port B1, and the oil port A of the closed plunger pump 4 can be communicated with the oil port A1;

[0033] Engine 5, the output shaft of the engine 5 is connected with the closed plunger pump 4;

[0034] A hydraulic motor 7, the output shaft of the hydraulic motor 7 is connected to the reducer;

[0035] Wherein, the oil port B of the hydraulic motor 7 communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com