Card stacking and putting mechanism

A technology of card and material blocking mechanism, which is applied in the direction of sending objects, stacking receiving devices, and thin material processing, etc. It can solve the problems of low efficiency of manual card codes, and achieve the effect of improving production efficiency and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

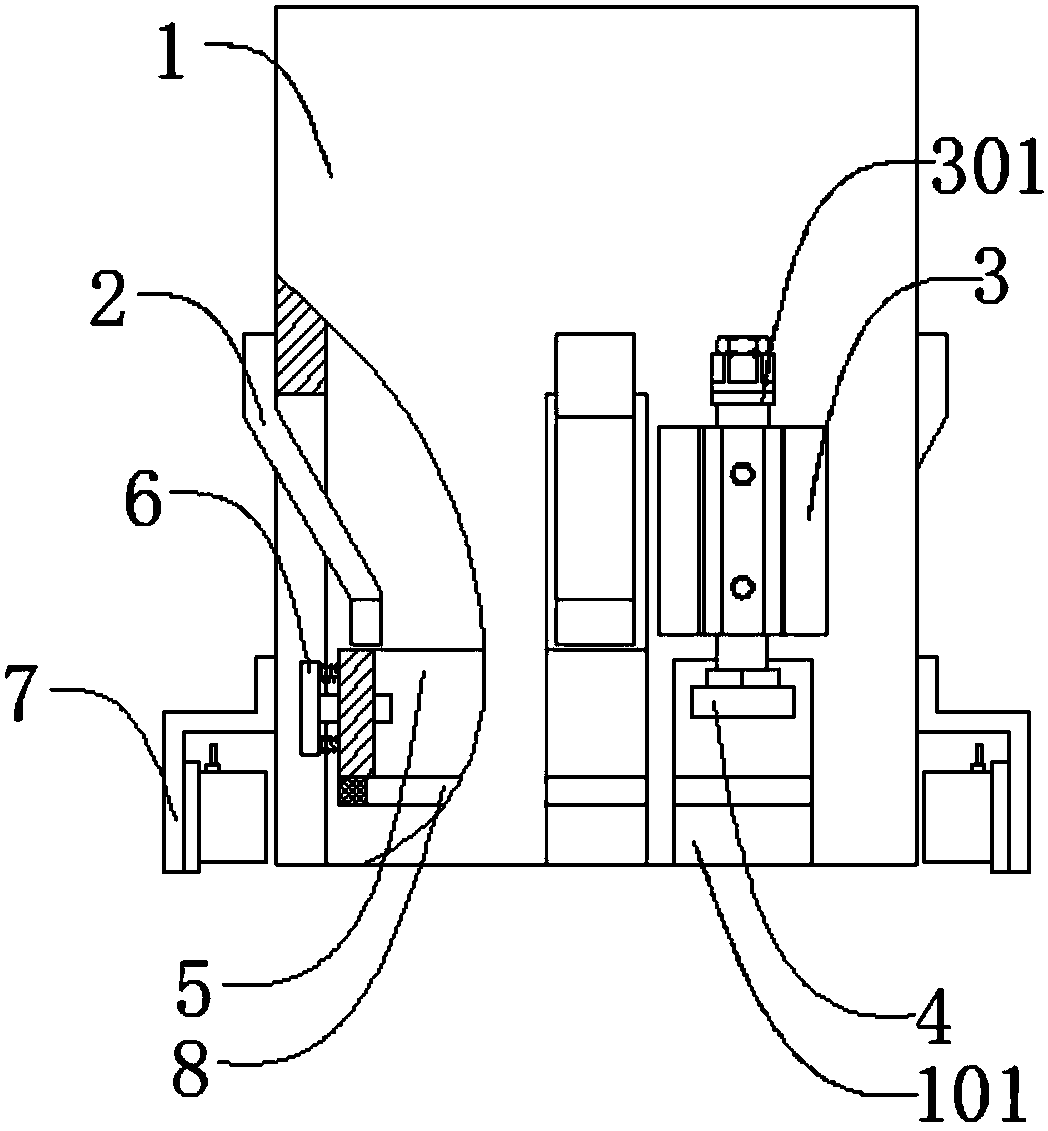

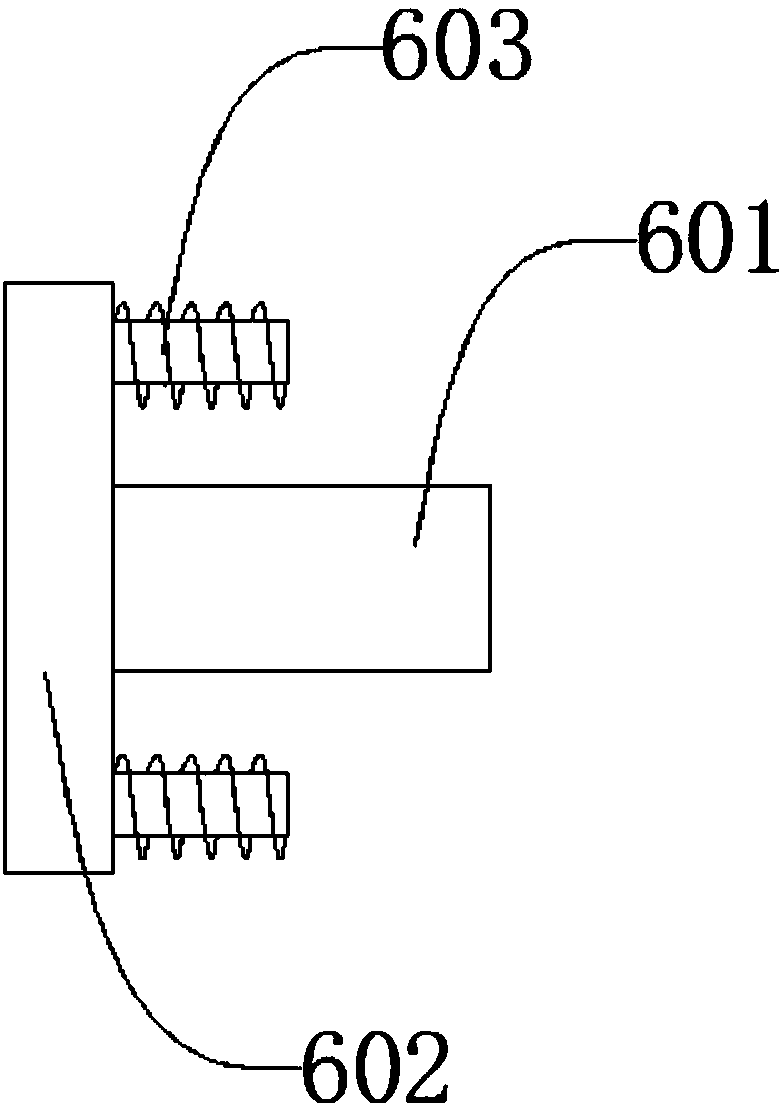

[0016] Such as figure 1 , figure 2 As shown, a card stacking mechanism includes a square material cylinder 1, a shrapnel 2, a cylinder 3, a connecting plate 4, a buffer sleeve 5, a material retaining mechanism 6, an electromagnet 7, and a silicone sleeve 8. The number of the shrapnel 2 is 4 The components are symmetrically arranged left and right, front and rear along the square material cylinder 1, the cylinder 3 is located outside the square material cylinder 1, the cylinder 3 is connected to the square material cylinder 1 by bolts, and the connecting plate 4 is located on the cylinder 3 The lower end runs through the square barrel 1. The connecting plate 4 is connected to the cylinder 3 by bolts. The buffer sleeve 5 is located on the side of the connecting plate 4 and inside the square barrel 1. The buffer sleeve 5 and the connecting plate 4 are connected by welding, and the buffer sleeve 5 is also provided with a stopper mechanism 6, and the electromagnet 7 is located at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com