Vibrating screen fault feature extraction method and fault monitoring system

A technology of fault characteristics and extraction methods, which is applied in the field of construction machinery, can solve problems such as economic losses of enterprises, difficult maintenance, equipment structure damage, etc., achieve good economic and social benefits, facilitate use and maintenance, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below through specific embodiments.

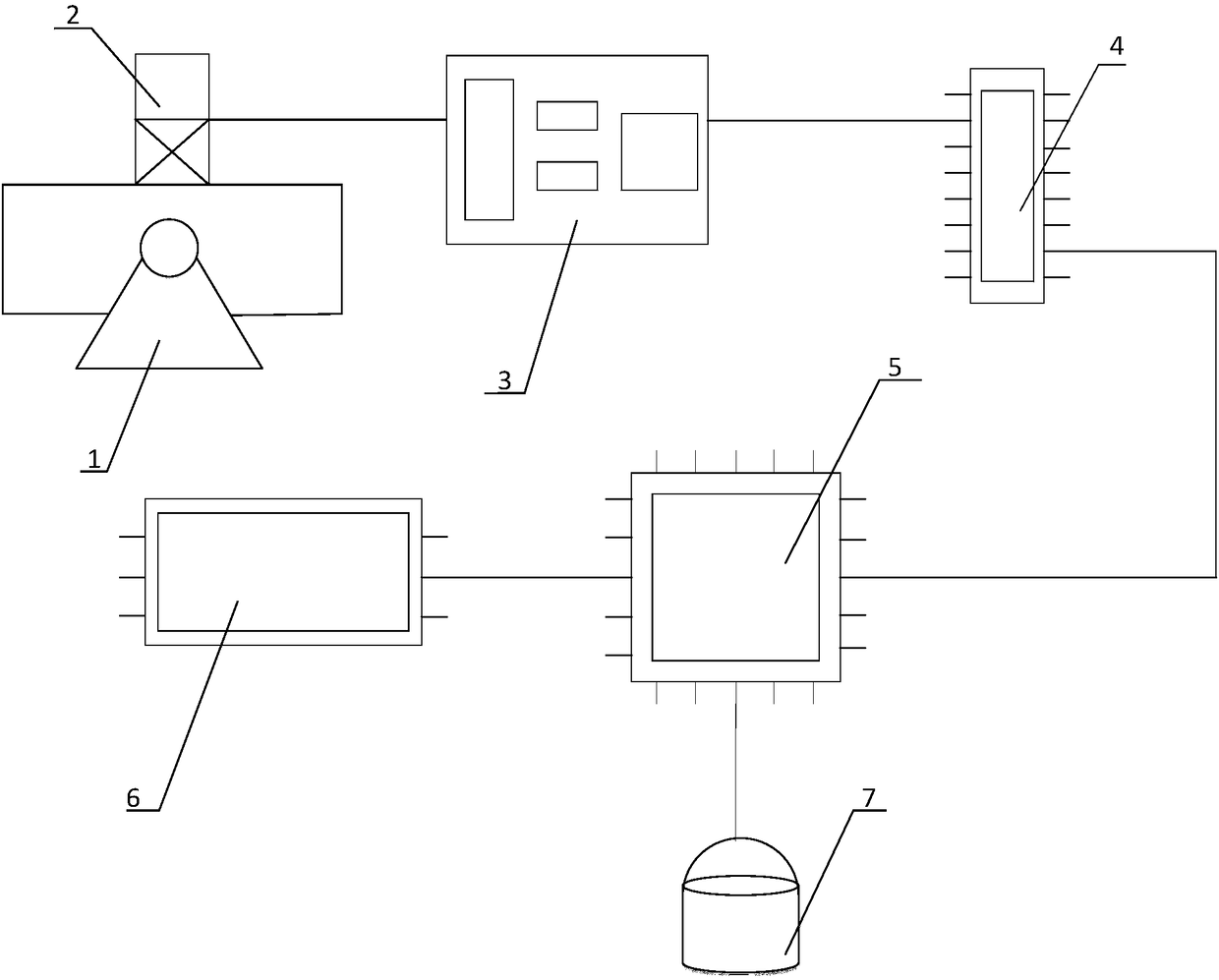

[0024] According to the vibrating screen dynamic model, a vibrating screen fault experiment platform is built, and the original information of fault characteristics is obtained through different types of fault experiments. There are three common types of faults, which are unbalanced excitation force faults, spring stiffness change faults and spring height change faults.

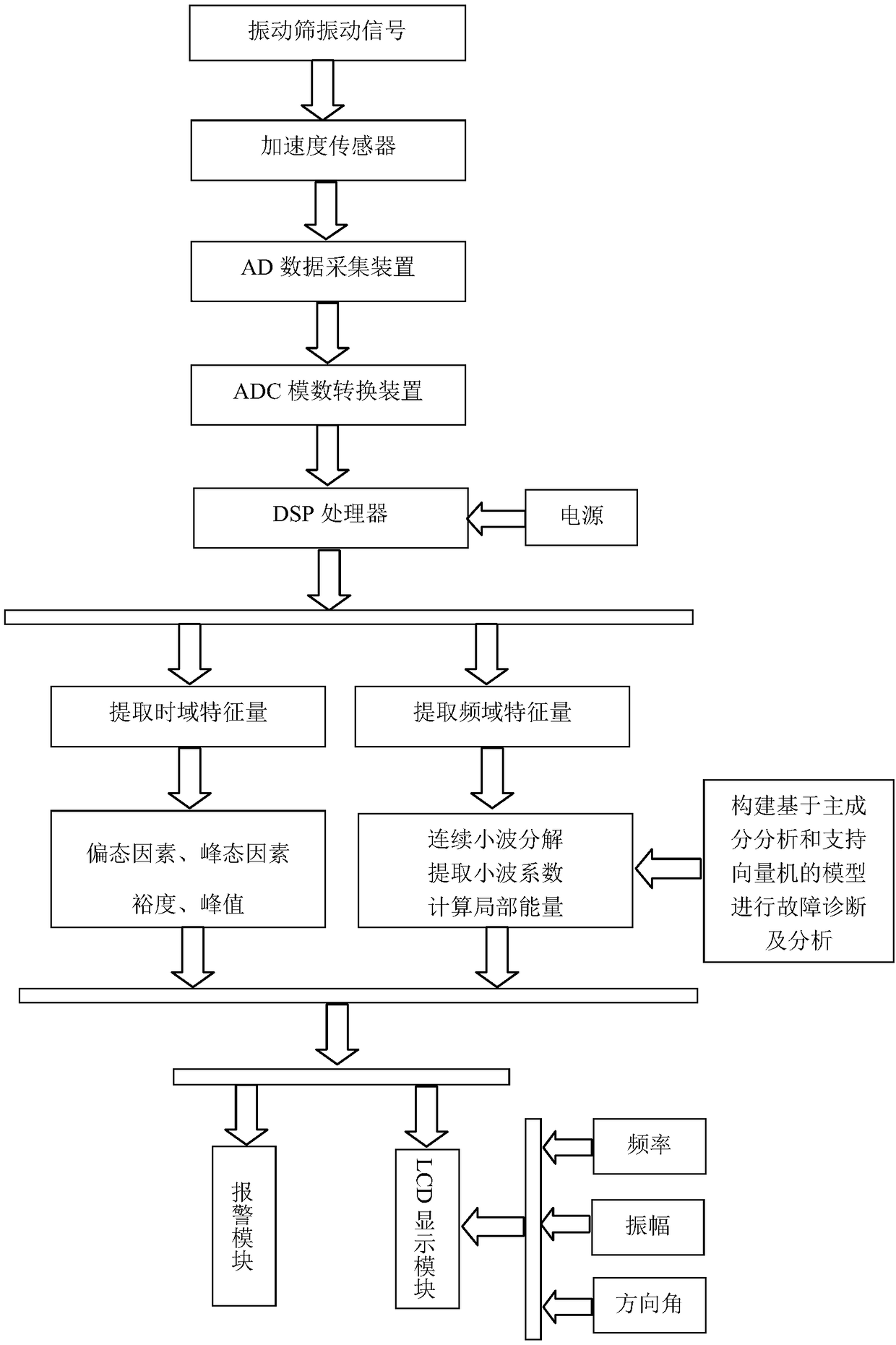

[0025] refer to figure 1 , a kind of vibrating screen fault feature extraction method of the present invention, the present invention comprises the following steps:

[0026] 1) Acquisition of the acceleration signal of the fault characteristics of the vibrating screen, which is an analog signal, converted into a digital signal through analog to digital.

[0027] 2) Select the skewness factor, kurtosis factor, margin, and peak value of the acceleration signal to extract time-domain feature quantities, and perform thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com