Calculation method for steel rail potential current distribution influences

A technology of current distribution and calculation method, applied in calculation, power track, complex mathematical operation, etc., can solve problems such as excessive rail potential and rail current, and achieve the effect of ensuring safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

[0031] Taking the case where two CRH3 EMUs are operated in the same power supply arm as an example, the present invention will be further elaborated, including the following steps:

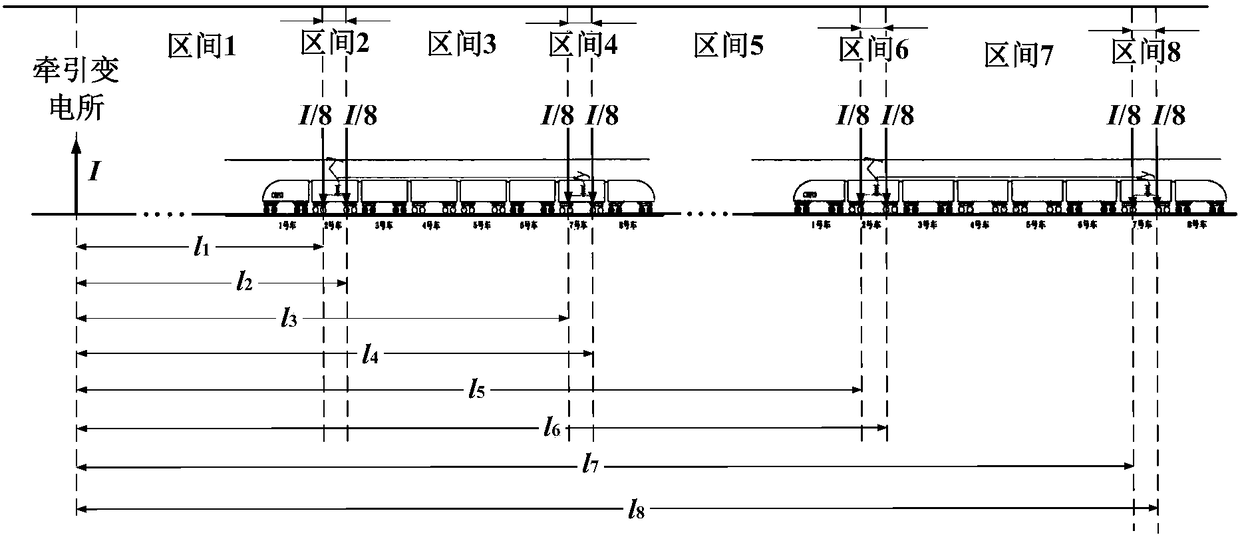

[0032] Step 1: Considering that the CRH3 EMU has 4 working grounding points, it is determined that the traction current in the power supply arm is injected into the rail-earth circuit in 8 parts, and is aggregated and flowed out at the traction substation; the feedback is fed back to the traction substation The total backflow current is decomposed into 8 parts, and the road section between the traction substation and the working grounding point farthest from the traction substation is divided into 8 different sections according to the injection position of each sub-return current on the rail.

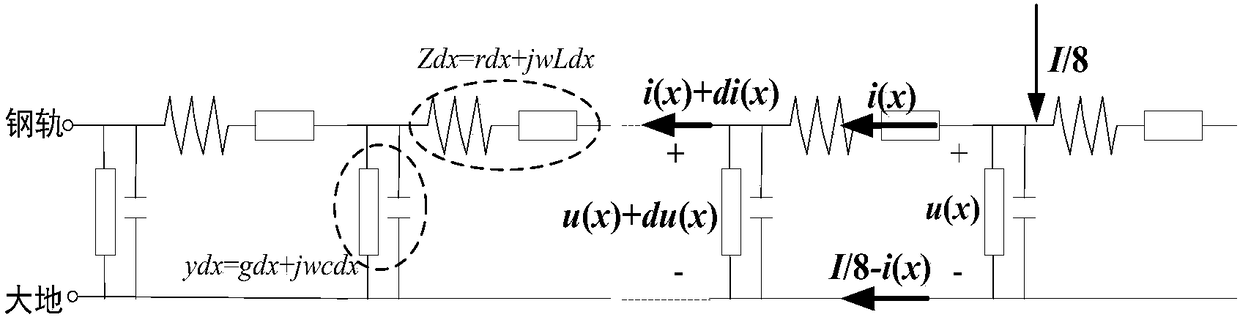

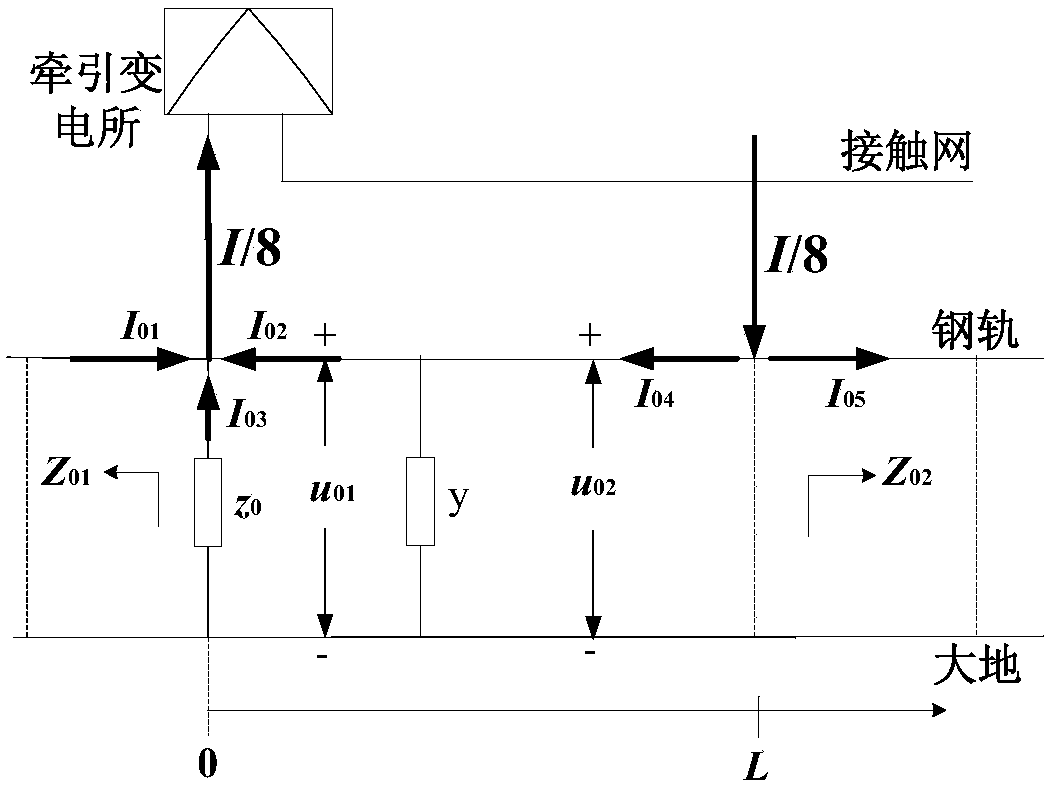

[0033] Step 2: Consider only a single sub-return current exists in the pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com