Arc extinguishing device

An arc extinguishing device and arc extinguishing technology, applied in high-voltage air circuit breakers, electrical components, electric switches, etc., can solve problems such as poor circuit contact, strong impact force, and large risk factor, so as to improve equipment safety and reduce airflow Impact force, the effect of improving the arc extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, objectives and beneficial effects realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

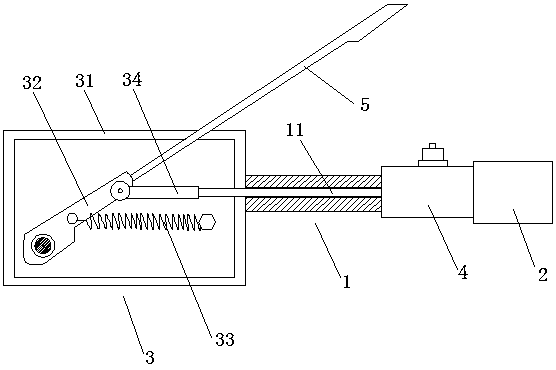

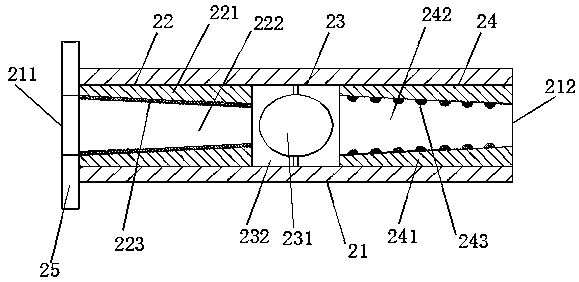

[0028] As shown in the figure, an arc extinguishing device includes an insulating sleeve 1 and a pull rod 11 arranged in the insulating sleeve 1. On one side of the insulating sleeve 1, a transmission mechanism 3 and a drain rod connected to the transmission mechanism are provided. 5. An arc extinguishing mechanism 4 is provided on the other side of the insulating sleeve 1;

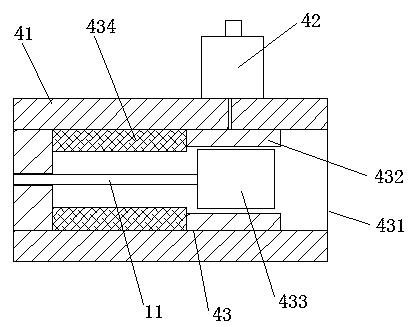

[0029] The transmission mechanism 3 includes a fixed sleeve 31 made of insulating material and a transmission assembly arranged in the fixed sleeve 31. The drainage rod 5 is connected with the pull rod 11 in the insulating sleeve 1 through the transmission assembly. The arc mechanism 4 includes an insulating housing 41, a terminal 42 arranged outside the insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com