An agricultural rice grading treatment equipment

A technology for grading treatment and rice, which is applied in agriculture, threshing equipment, agricultural machinery and implements, etc. It can solve the problem of inability to filter rice grains, and achieve the effect of improving convenience, ease of movement and reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

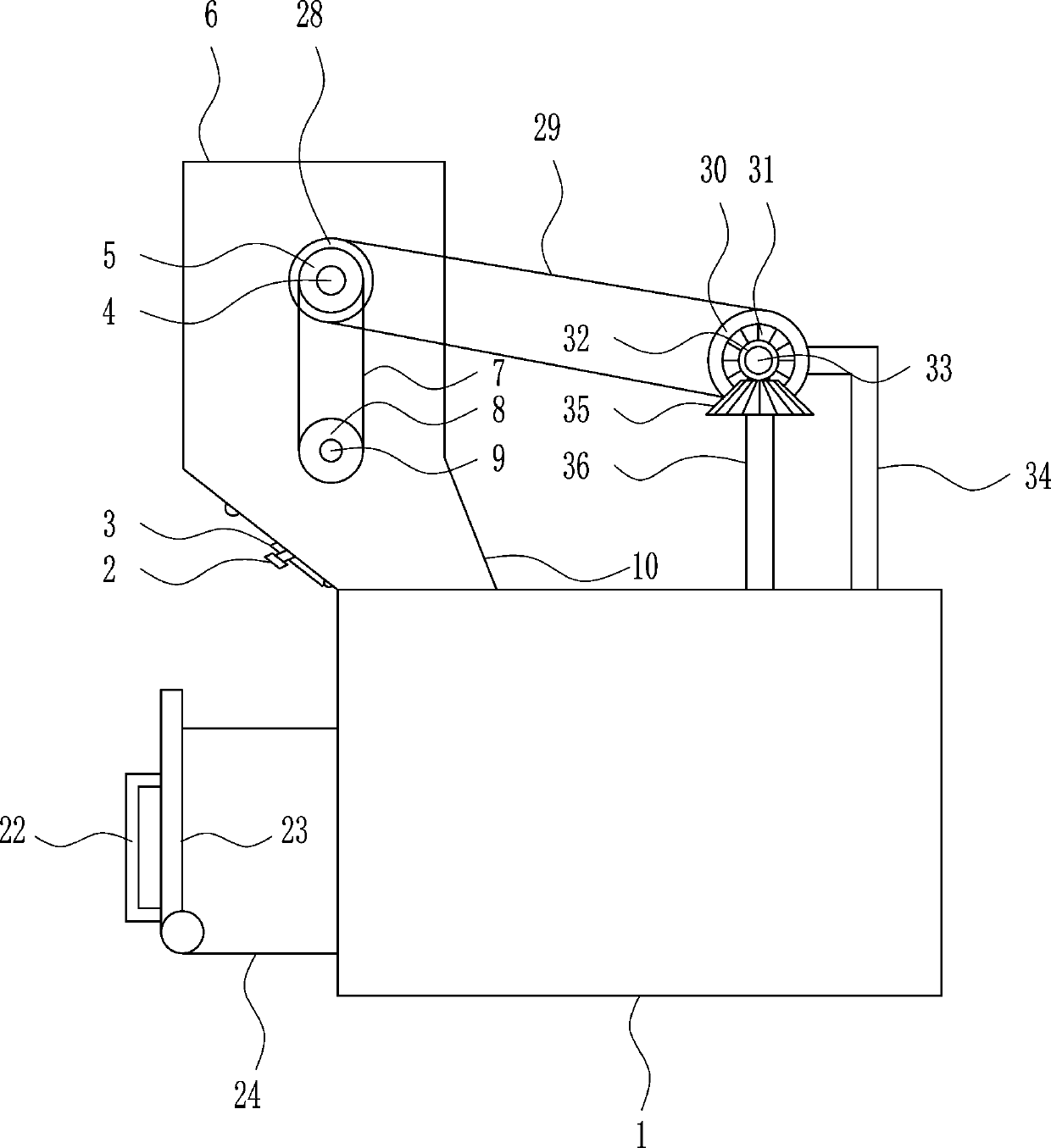

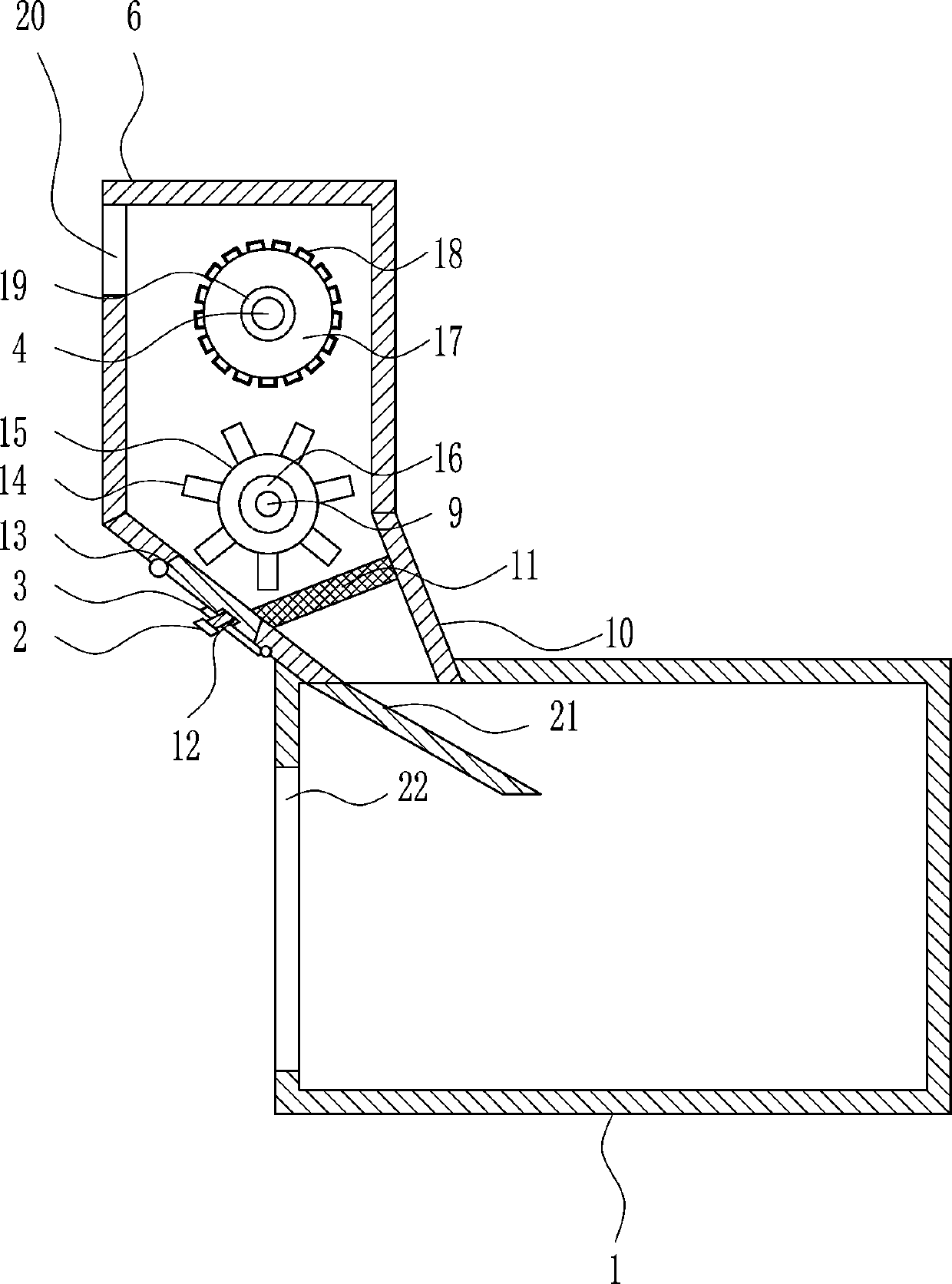

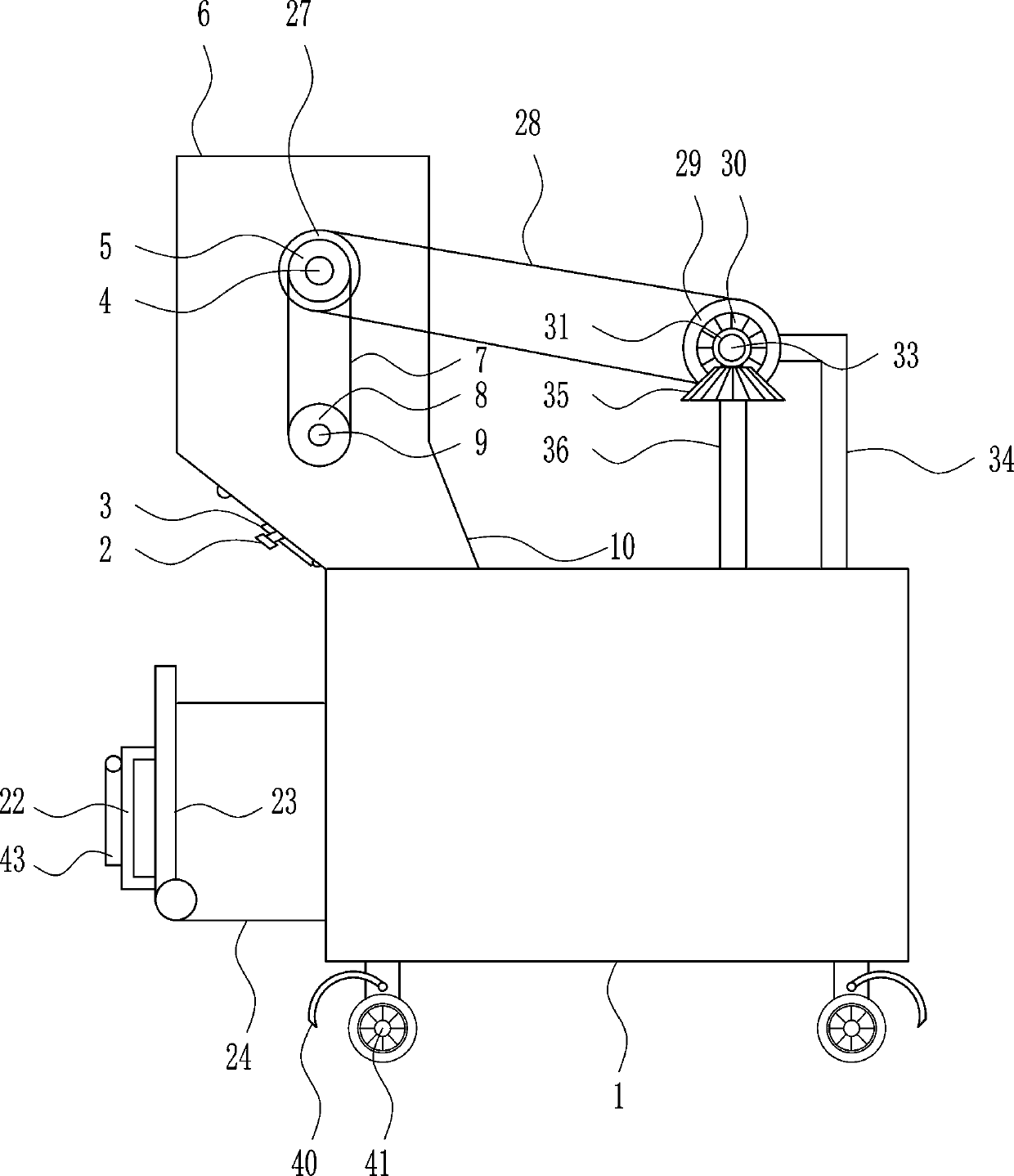

[0032] A kind of agricultural rice grading processing equipment, such as Figure 1-7 As shown, it includes a collection box 1, a bolt 2, a clamping plate 3, a first rotating shaft 4, a first transmission wheel 5, a processing frame 6, a first transmission belt 7, a second transmission wheel 8, a second rotation shaft 9, and a lower hopper 10 , filter screen 11, nut 12, baffle plate 13, rice paddle 14, the first cylinder 15, the first bearing seat 16, the second cylinder 17, hoop 18, the first motor 19 and the inclined plate 21; There is a discharge port 22 on the side; the lower hopper 10 is fixed on the top of the collection box 1 near the discharge port 22, the filter screen 11 is fixed in the lower hopper 10, and the baffle 13 is hinged on the lower hopper 10 near the discharge port 22 The nut 12 is embedded in the baffle 13; the clamp 3 is hinged on one side of the lower hopper 10 and is located below the baffle 13; the bolt 2 runs through the clamp 3 and is screwed with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com