Tubular reactor catalyst stirring and distributing device

A tube-and-tube reactor and distributing device technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve problems such as uneven distribution, and achieve the effects of accurately controlling the drop, avoiding shaking, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

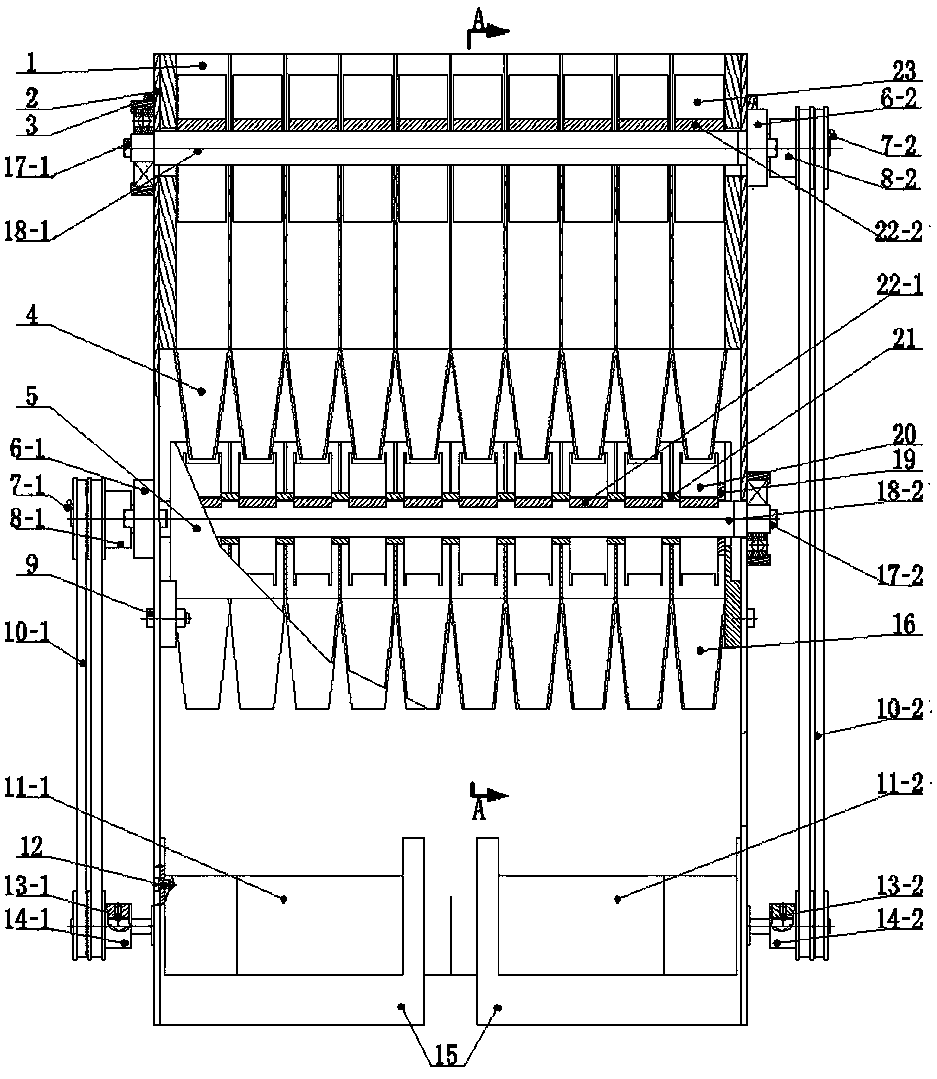

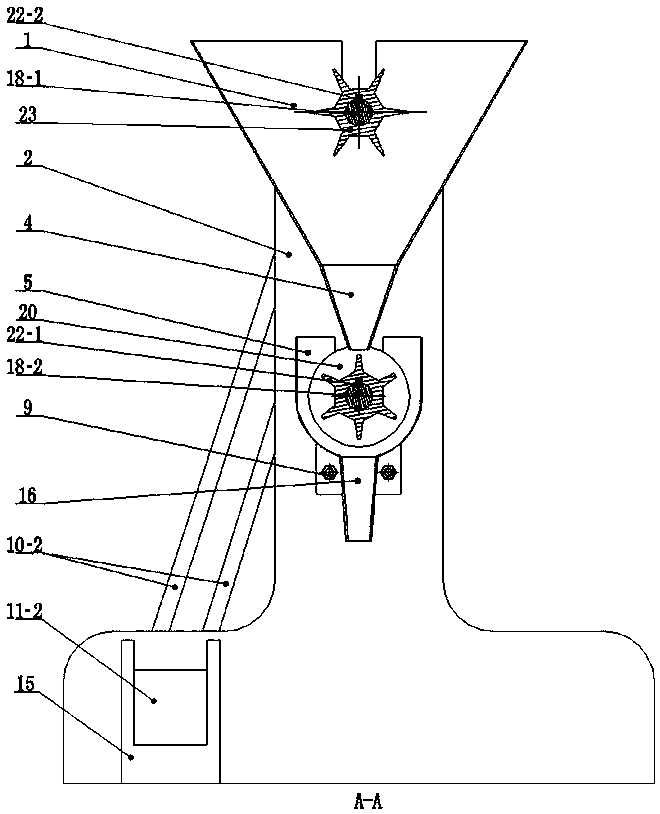

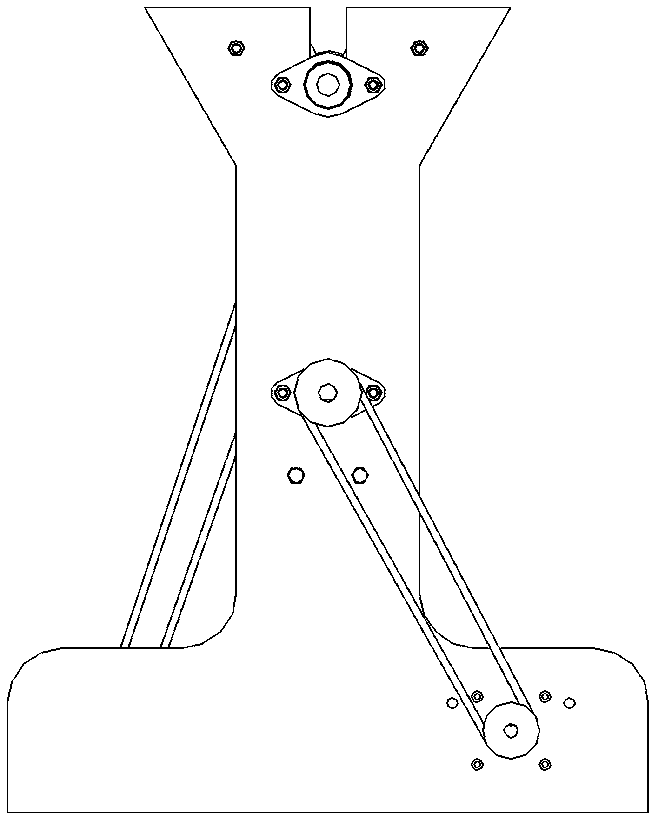

[0033] Referring to the accompanying drawings, a catalyst stirring and distributing device for a tubular reactor has a distribution box 1 (see Figure 6 ), the distribution box 1 is evenly divided into 10 storage tanks, and a long conical drop hopper 4 is sequentially connected to the bottom of the 10 storage tanks (see Figure 8 ), spacer box 5 (see Figure 7 ) and short conical drop hopper 16 (see Figure 9 ); the material distribution box 1 is an inverted regular triangle, the bottom corner of the upper opening of the storage tank is cut off, and the cut bottom corner is butt-welded with the long conical falling hopper 4, and the long conical falling hopper 4 inlet is respectively connected to the storage tank Corresponding to the discharge port, the material distribution box 1 is fixed on the support plates 2 on both sides by fastening bolts 3 . A stirring wheel 23 is provided in the distribution box 1 (see Figure 10 ), the main transmission shaft 18-1 and the key 22-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com