Ultralow-concentration copper-molybdenum separating flotation method

An ultra-low concentration, copper-molybdenum technology, used in flotation, solid separation and other directions, can solve the problems of poor flow in the production process and the grade of molybdenum concentrate does not meet the requirements, so as to reduce floating, run smoothly, and ensure quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Include the following steps:

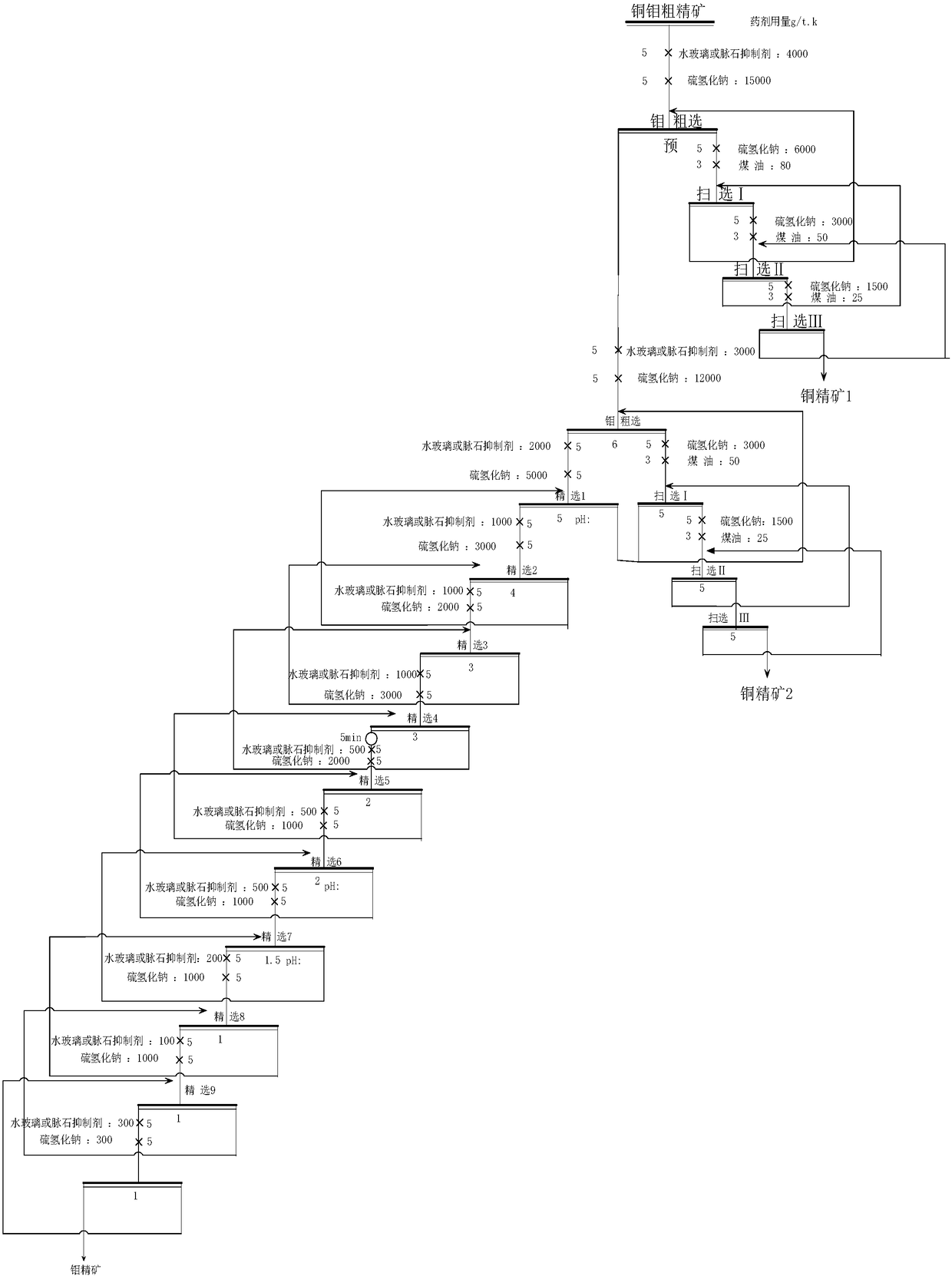

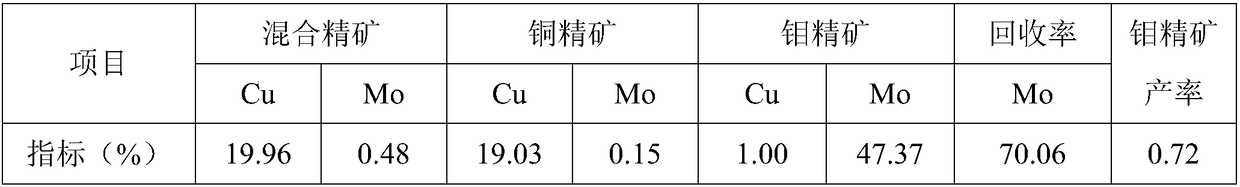

[0021] Step 1: One pre-rougher selection, three pre-sweeping, calculated according to the weight percentage concentration of the pulp: the pre-roughering operation pulp concentration is 15%; the first pre-sweeping operation pulp concentration is 12%; the second pre-sweeping operation The pulp concentration is 10%; the pulp concentration of the third pre-sweeping operation is 8%; the pre-roughing operation foam enters the first roughing operation, and the third pre-sweeping operation separates the tailings into copper concentrate 1. This step is aimed at low Grade, high muddy skarn copper and molybdenum ores, especially copper-molybdenum mixed concentrates with low molybdenum grade and high mudification characteristics, reduce the flotation concentration, reduce the floating of muddy minerals, and remove most of the muddy minerals and molybdenum in advance Other impurities effectively improve the stability of the subsequent copper-molybdenu...

Embodiment 2

[0026] Include the following steps:

[0027] Step 1: one pre-roughering, three times pre-sweeping, in terms of pulp weight percentage concentration: the pre-roughering operation pulp concentration is 17.5%; the first pre-sweeping operation pulp concentration is 12.5%; the second pre-sweeping operation The pulp concentration is 11.5%; the pulp concentration of the third pre-sweeping operation is 9%; the pre-roughering operation foam enters the first roughing operation, and the third pre-sweeping operation separates the tailings into copper concentrate 1;

[0028] Step 2: One roughing, three times sweeping, according to the pulp weight percentage concentration: the pulp concentration of the roughing operation is 9%; the pulp concentration of the first sweeping operation is 9%; the pulp concentration of the second sweeping operation is 9% The slurry concentration of the third sweeping operation is 9%; the tailings separated by the third sweeping operation are copper concentrate 2...

Embodiment 3

[0032] Include the following steps:

[0033] Step 1: One pre-roughing and three pre-sweeping, based on the weight percentage concentration of the pulp: the pre-roughing operation has a pulp concentration of 20%; the first pre-sweeping operation has a pulp concentration of 15%; the second pre-sweeping operation The pulp concentration is 13%; the pulp concentration of the third pre-sweeping operation is 10%; the pre-roughering operation foam enters the first roughing operation, and the third pre-sweeping operation separates the tailings into copper concentrate 1;

[0034] Step 2: One roughing, three times sweeping, according to the pulp weight percentage concentration: the pulp concentration of the roughing operation is 10%; the pulp concentration of the first sweeping operation is 10%; the pulp concentration of the second sweeping operation is 10% The slurry concentration of the third sweeping operation is 10%; the tailings separated by the third sweeping operation are copper c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com