Mechanical arm material moving and folding mechanism of stamping assembly line

A robotic arm and assembly line technology, applied in the field of manipulator moving materials, can solve the problems of inability to adapt to the speed of the punching line, affecting the improvement of efficiency, etc., and achieve the effects of precise and controllable flipping effect, convenient disassembly and assembly, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

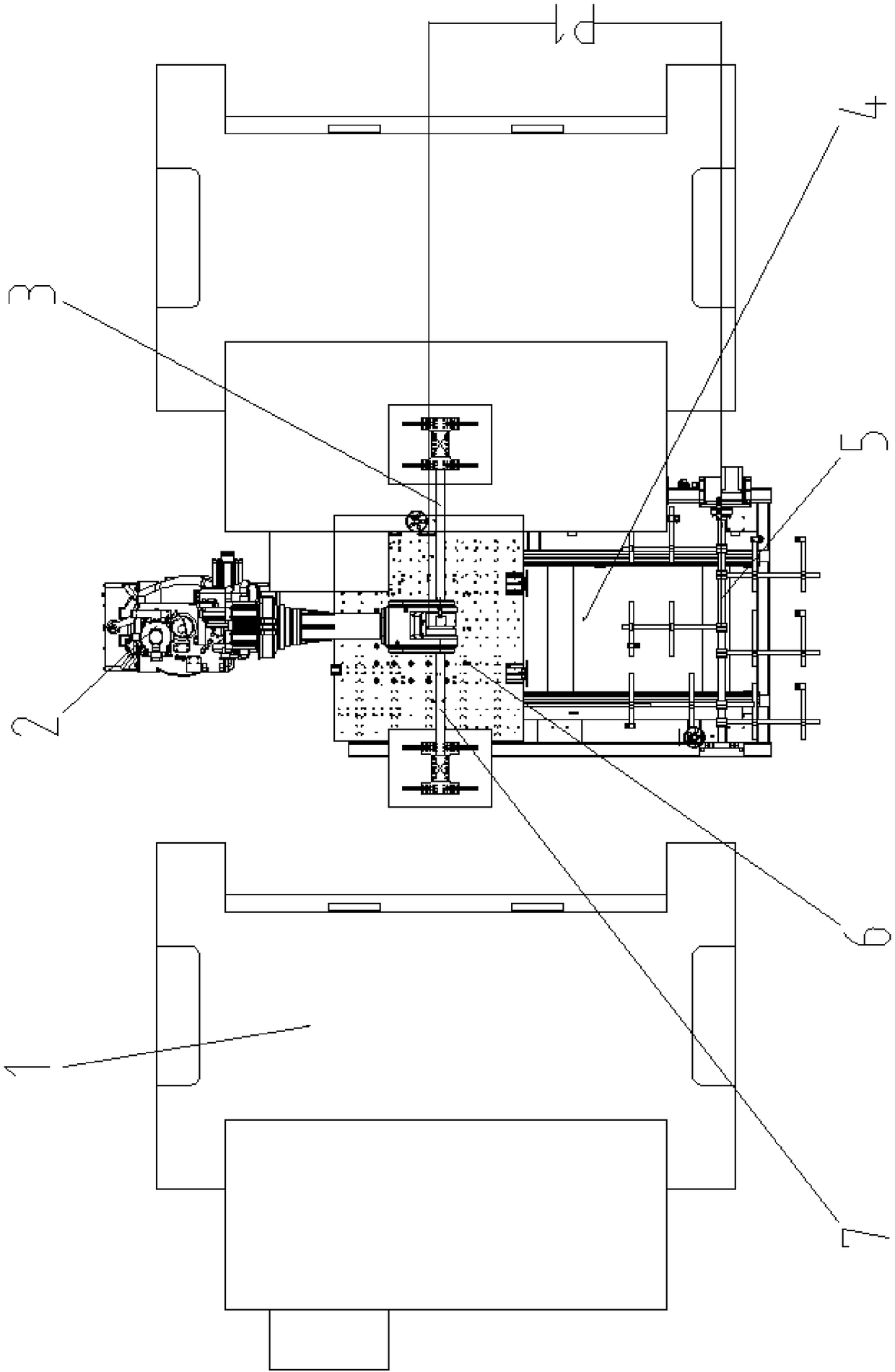

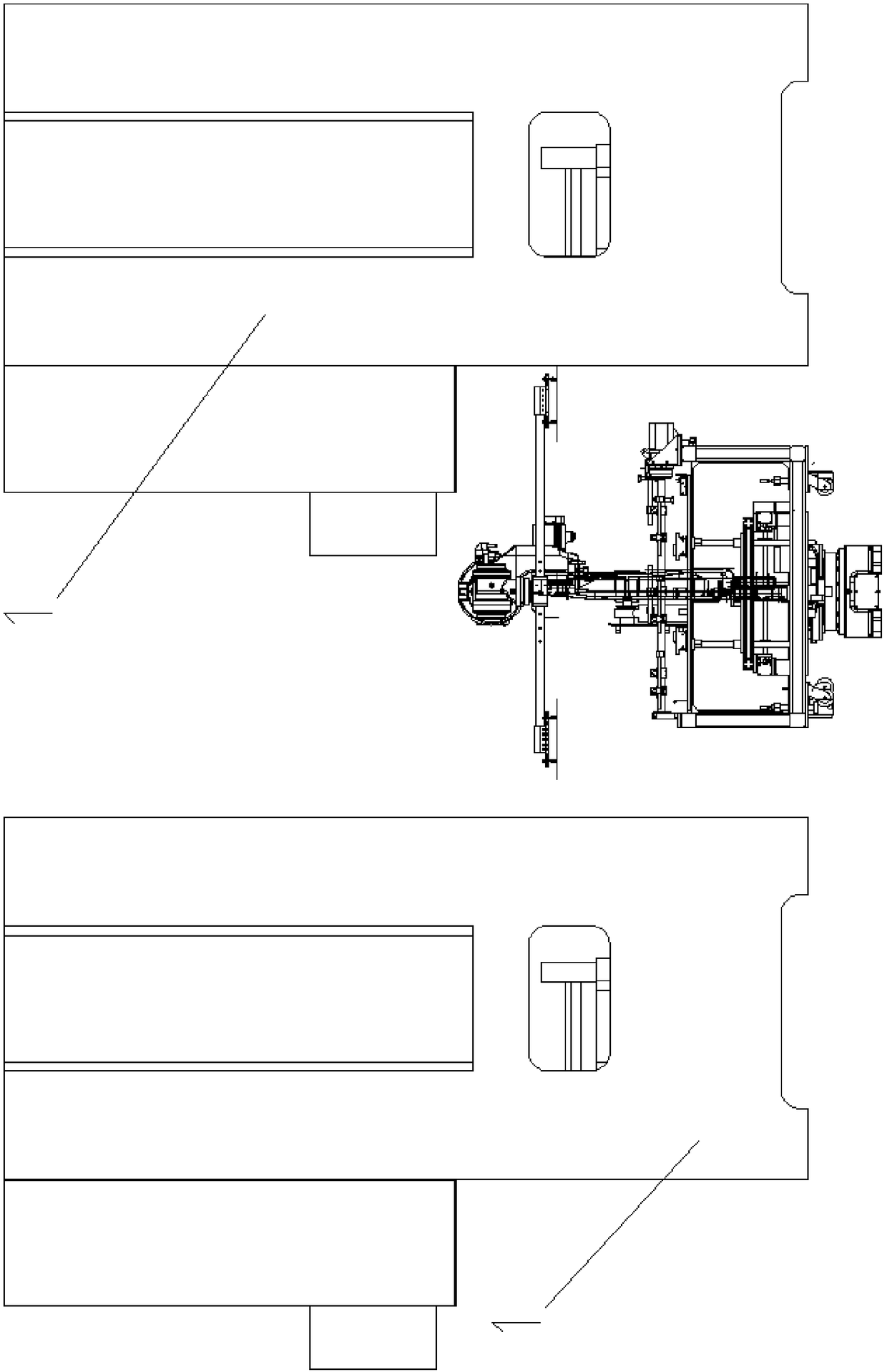

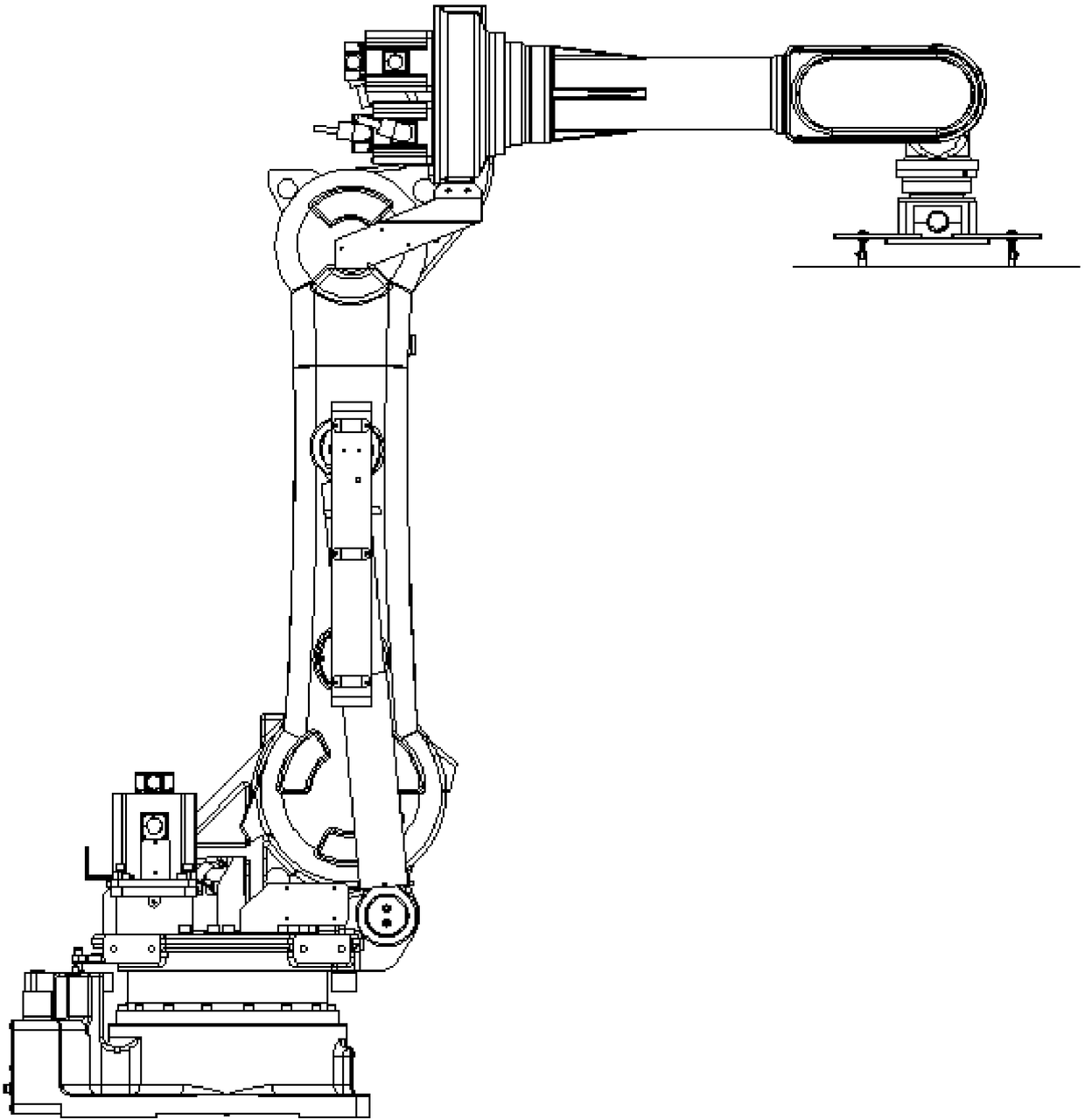

[0038] In order to achieve the purpose of the present invention, a mechanical arm material transfer and folding mechanism of a stamping assembly line includes: a mechanical arm 2, equipped with a double arm composed of a fixed arm 3 and a detachable arm 7, the fixed arm 3, the detachable arm The type arm 7 is coaxially arranged and extends in the opposite direction, the manipulator 2 is arranged between two punches 1, the fixed arm 3 and the detachable arm 7 are connected with a rotating shaft; the turning mechanism 4 is arranged on the same Between the two punches 1 , the turning mechanism 4 is equipped with an overturn frame 5 and a secondary positioning platform 6 arranged along the direction perpendicular to the line connecting the two punches 1 .

[0039] The beneficial effect of adopting the above-mentioned technical solution is that the operation effi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com