Mounting tool for a super-large type door leaf

It is a technology for installing tooling and oversize, which is applied in metal processing, manufacturing tools, metal processing equipment, etc. It can solve the problems of large manpower and material resources, low efficiency, and inability to use cranes, so as to reduce the probability of stress concentration and ensure stability. , Increase the effect of the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

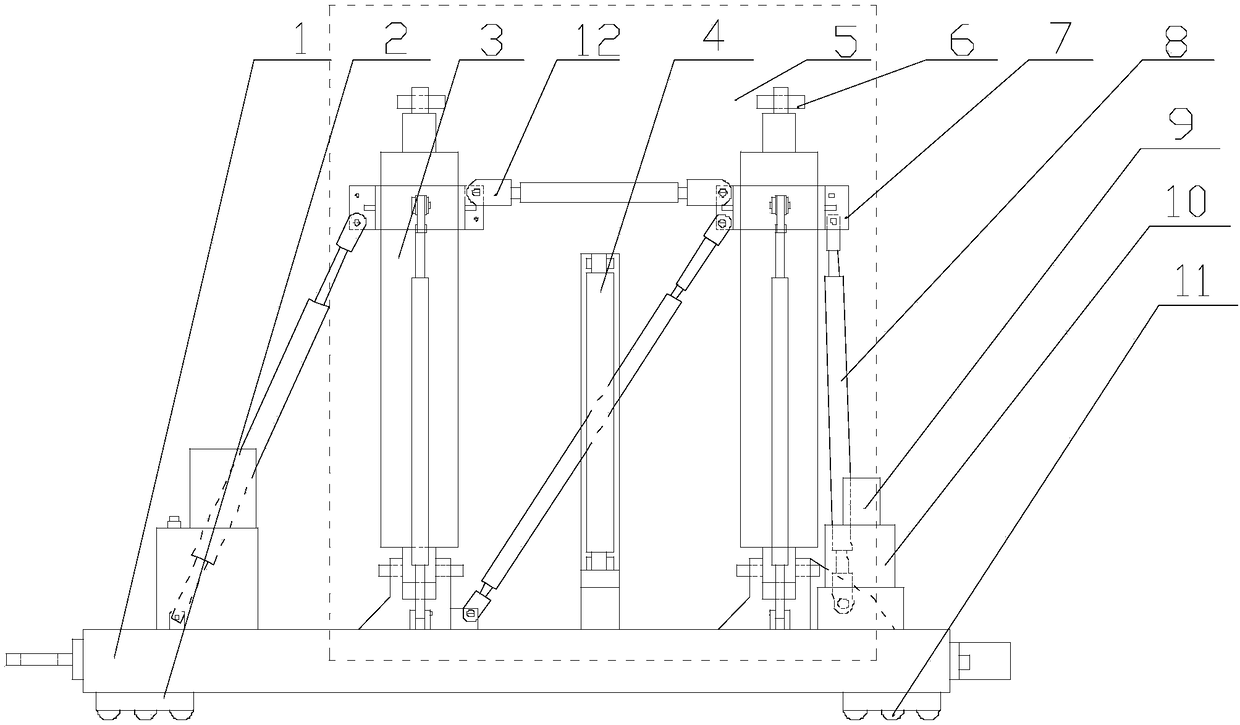

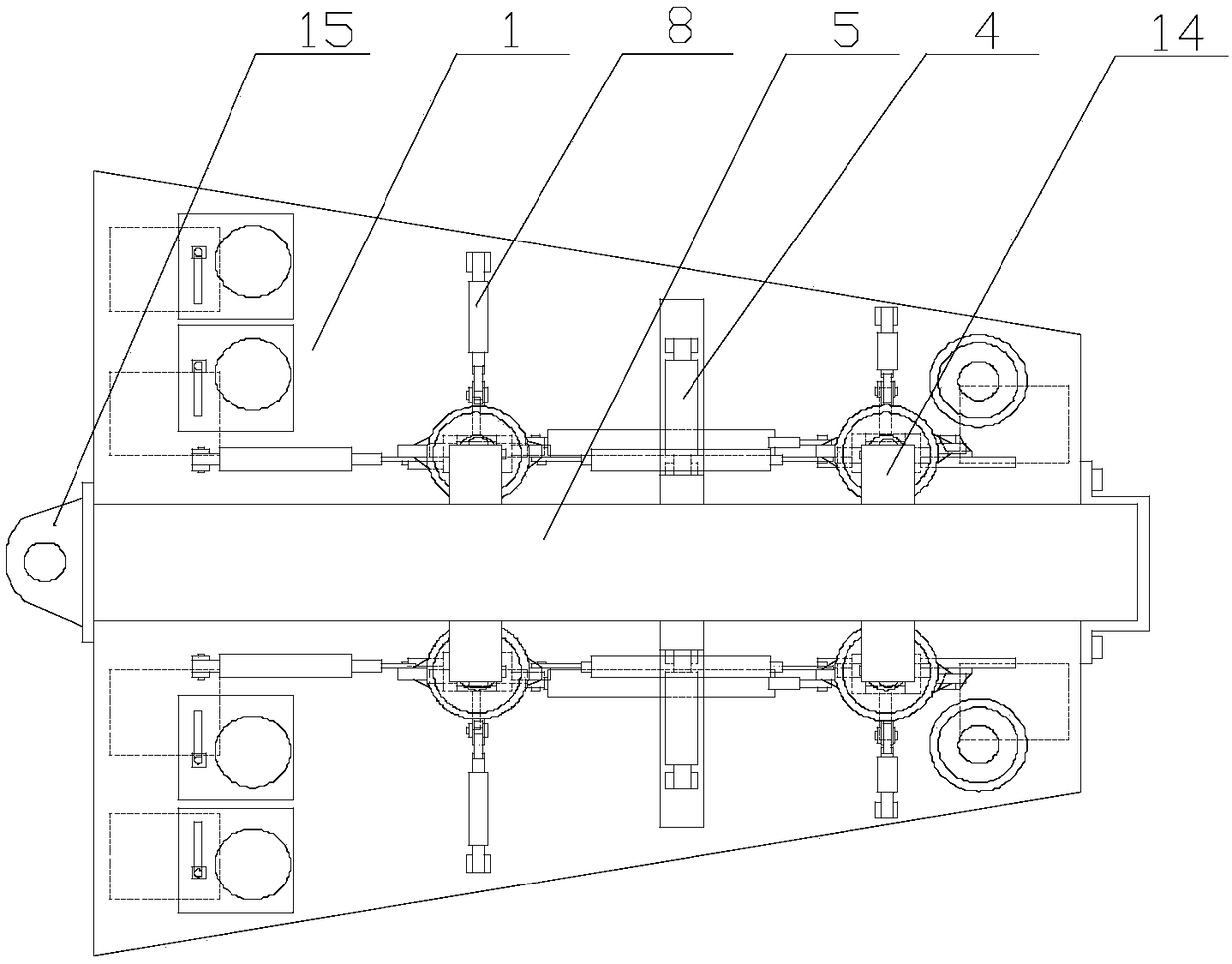

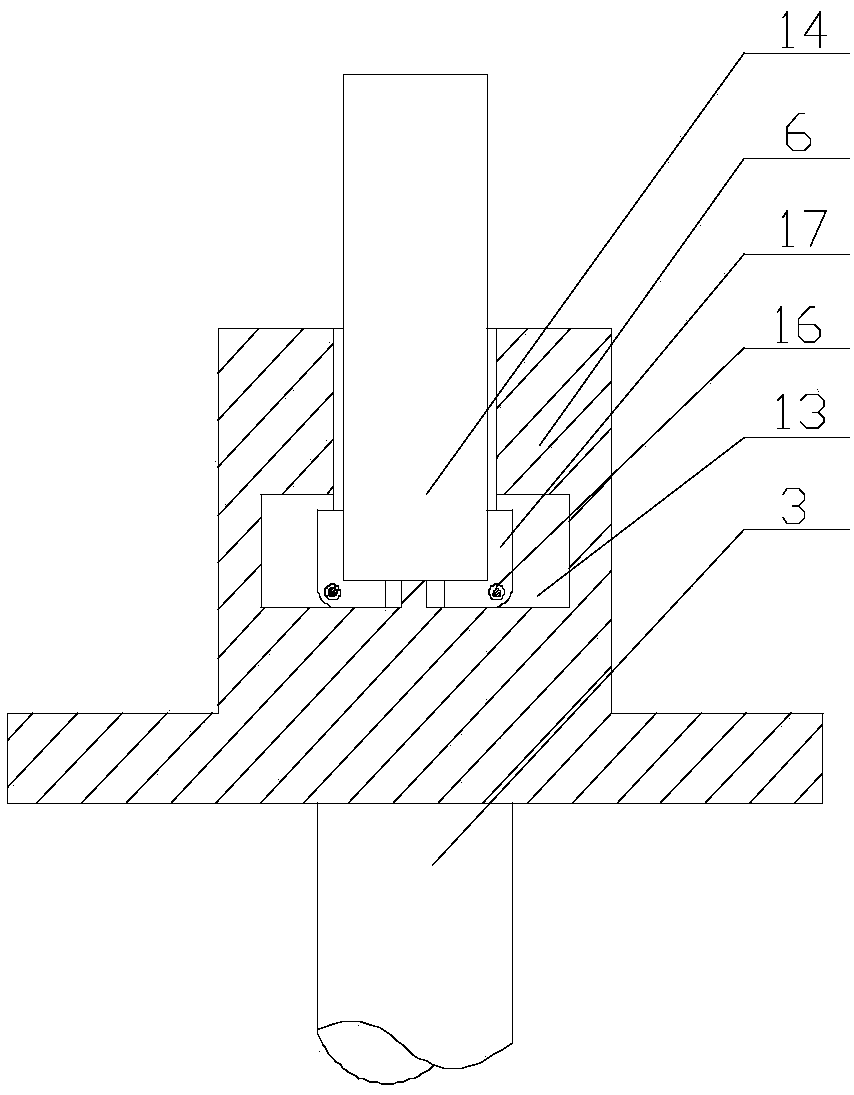

[0025] Such as Figure 1~3 As shown, the present embodiment includes a base 1, four oil cylinders 3 are arranged on the upper surface of the base 1, and a support head 6 is provided on the output end of each of the oil cylinders 3, and a limited opening is opened inside the support head 6. Position cavity 13, on the upper end surface of support head 6, there is a card slot communicating with limit cavity 13. The wall is provided with a central shaft 16, and the L-shaped block 17 is arranged on the central shaft 16 by a torsion spring. The ends of the horizontal sections of the two blocks 17 are oppositely arranged, and the position of the limiting cavity 13 in the horizontal direction The length is greater than the width of the clamping groove in the horizontal direction; in the initial state, the horizontal section of the clamping block 17 forms an acute angle with the bottom surface of the limiting cavity 13, when the output end of the oil cylinder 3 pushes the lifting lug ...

Embodiment 2

[0028] Such as Figure 1~3 As shown, in this embodiment, a snap ring 7 is provided on the upper outer peripheral wall of each of the oil cylinders 3, and a plurality of diagonal struts 8 are hingedly arranged on the base 1, and the upper ends of the diagonal struts 8 Hinged with the clasp 7, each of the diagonal struts 8 forms an acute angle with the upper surface of the base 1, and a boss is hinged on the upper surface of the base 1, and the bottom of the oil cylinder 3 is hinged with the upper end of the boss. Further, due to the different models and sizes of the door leaf 5, in order to ensure that the door leaf 5 can maintain a stable clamped state during the movement or transfer process, the applicant provided a boss on the base 1, while the oil cylinder 3 The snap ring 7 is installed in the upper part of the door, and the snap ring 7 and the oil cylinder 3 are supported and fixed by a plurality of length-adjustable diagonal struts 8, that is, according to the specific mo...

Embodiment 3

[0032] Such as Figure 1~3 As shown, the present embodiment also includes two right-angled triangular brackets 4, two guide rails are symmetrically arranged on the upper surface thereof along the mid-perpendicular line of the base 1, and the bracket 4 is slidably arranged on the guide rails, and on the base 1 A baffle is arranged on the baffle, and a screw hole is provided on the baffle, and the screw rod is connected with the bracket 4 after passing through the screw hole; Further, two triangular brackets 4 are arranged on the upper surface of the base 1, that is, before the door leaf 5 is hoisted and placed on the base 1, the distance between the two brackets 4 is greater than the thickness of the door leaf 5, when the door leaf 5 is placed on the base 1 , by turning the screw rod, the two brackets 4 are moved to the two side walls of the door leaf 5 respectively, until a right-angled side of the leg remains in close contact with the side walls of the door leaf 5 .

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com