Intravascular stent with developing function

A vascular stent and function technology, applied in the field of vascular stents, can solve the problems of insufficiently clear images, difficult to distinguish the position and shape of the stent, and inability to accurately locate the stent, and achieve the effect of solving the invisible problem, improving safety, and preventing relative displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

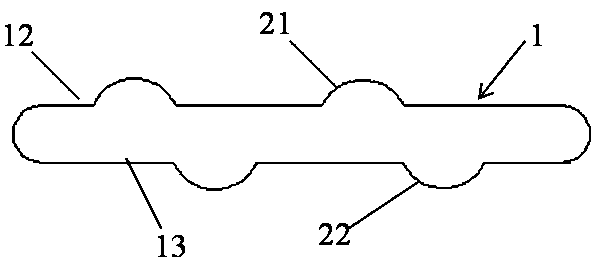

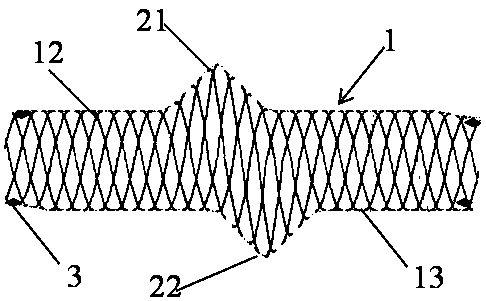

[0037] This embodiment provides a vascular stent with a developing function, which includes a stent body 1 and a developing structure 3 , the stent body 1 has a hollow tubular structure, and the tube wall has a hollow mesh structure. The bracket body 1 is divided into a symmetrical upper tube wall 12 and a lower tube wall 13 by the plane where the central axis of the hollow tubular structure is. The stent body 1 in this embodiment is made of titanium alloy. The diameter of the stent body 1 gradually decreases from the middle to both ends, and the diameter of the two ends is 75%-80% of the diameter of the middle part. In the non-slip vascular stent provided by the present invention, the length of the stent body 1 is 0.5-20 cm, and the diameter of the stent body 1 is 1.0-8.0 cm.

[0038] The developing structure 3 is arranged in the mesh-shaped hollow part of the support body 1 and connected with the support body 1 . The area of the developing structure 3 is 40%-60% of the a...

Embodiment 2

[0041] This embodiment provides a titanium alloy material, the titanium alloy has high stability, good biocompatibility, and can also play an anti-infection function in the body. The titanium alloy includes 14.3% niobium, 5.2% zirconium, 4.7% molybdenum, 2.4% copper, 0.18% palladium in mass percentage, and the balance is titanium and unavoidable impurities, wherein oxygen ≤ 0.1%, carbon ≤ 0.04%, Nitrogen ≤ 0.03, hydrogen ≤ 0.002%.

[0042] The titanium alloy is prepared by the following method:

[0043] Titanium powder and various alloy element powders are weighed according to the above-mentioned raw materials and mass ratios, ball milled and mixed, and mechanically pressed to form a billet according to the powder metallurgy billet making process in the prior art. The blank is placed in the heat preservation barrel, and then the heat preservation barrel is put into the microwave sintering furnace. The furnace chamber of the microwave sintering furnace is evacuated to a vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com