Automatic assembly machine for connection-wire iron shells

An automatic assembly machine and connecting line technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, riveting dimensional errors, and large safety hazards, so as to reduce labor costs and improve accuracy. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

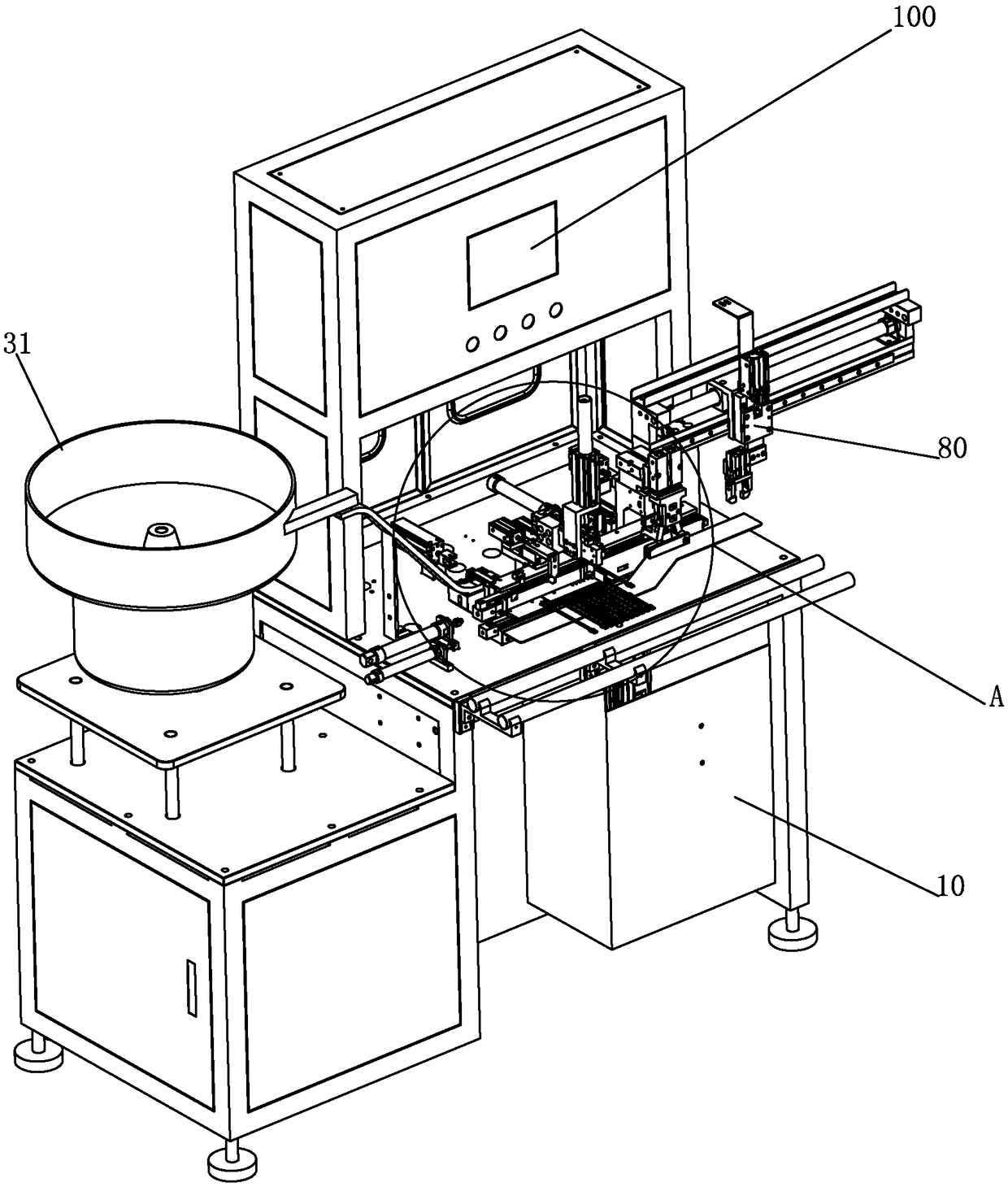

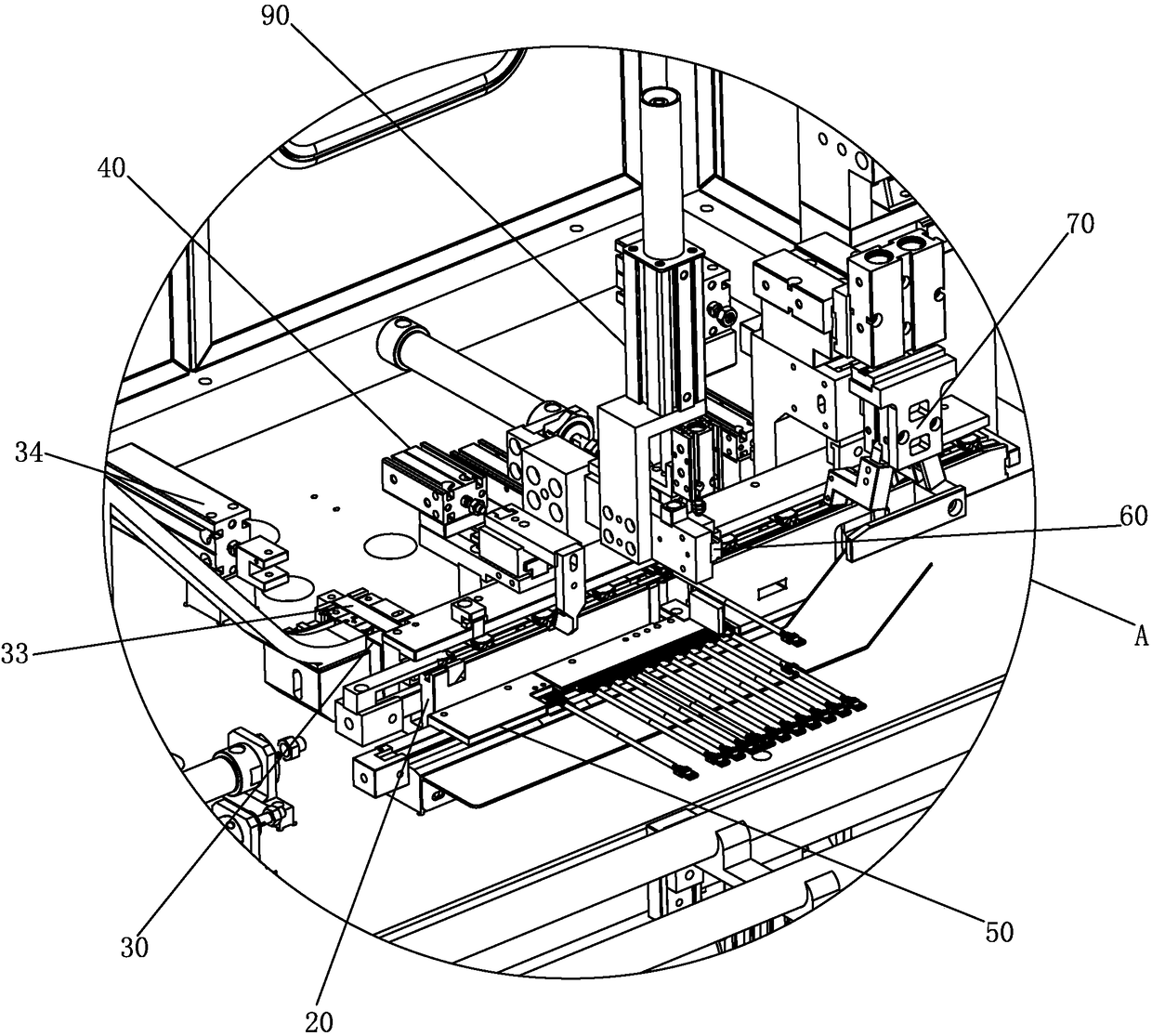

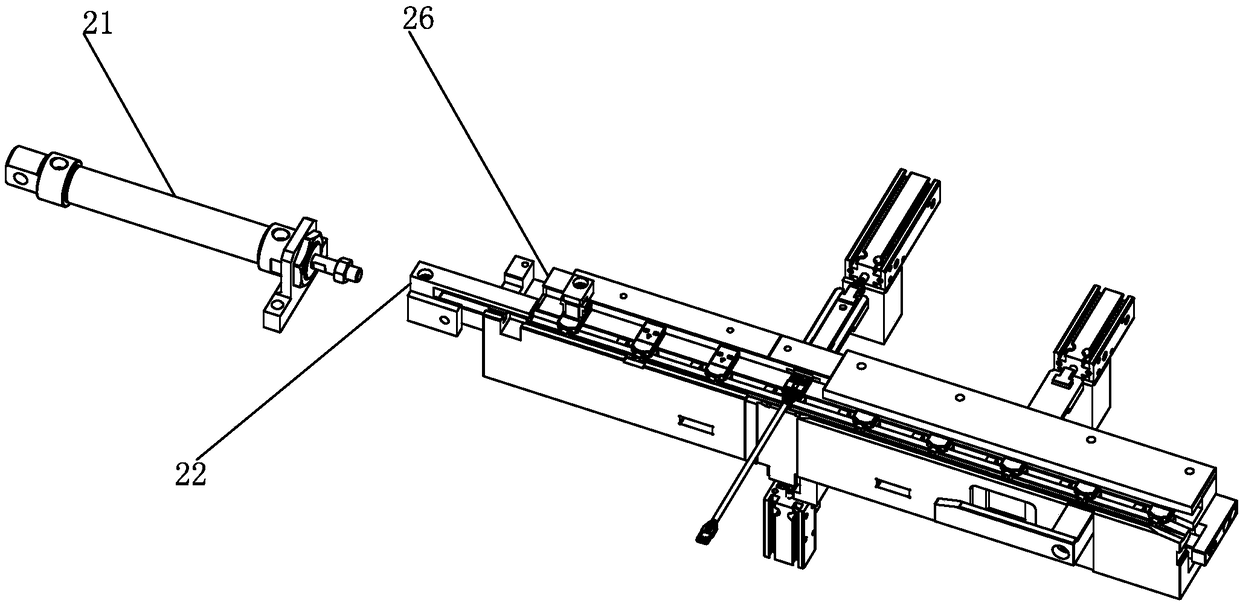

[0026] Such as Figure 1-9 As shown, an automatic assembly machine for connecting wire iron shells includes a control panel 100, a machine base 10 and a main track mechanism 20 arranged on the machine base 10. The main track mechanism 20 includes a main track 26 and a main track set on the main track 26. The iron shell conveying rod 22 inside, one end of the iron shell conveying rod 22 is provided with a conveying cylinder 21 that drives the iron shell conveying plate to move left and right along the main track mechanism 20, and the main track 26 is sequentially provided with feeding cylinders along the feeding direction. Material mechanism 30, iron shell stretching mechanism 40, wire loading mechanism 60, riveting mechanism 70 and automatic wire taking mechanism 80, the outside of the wire loading mechanism 60 is provided with a wire arranging mechanism 50, and the upper end of the wire loading mechanism 60 is provided with There is a pre-pressing mechanism 90, the feeding me...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap