Efficient computer numerical control (CNC) machining device and method

A processing device and high-efficiency technology, applied in positioning devices, feeding devices, metal processing equipment, etc., can solve the problems of complex tool changing mechanism, low production efficiency and high production cost, and achieve convenient use, simple structure, and production cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

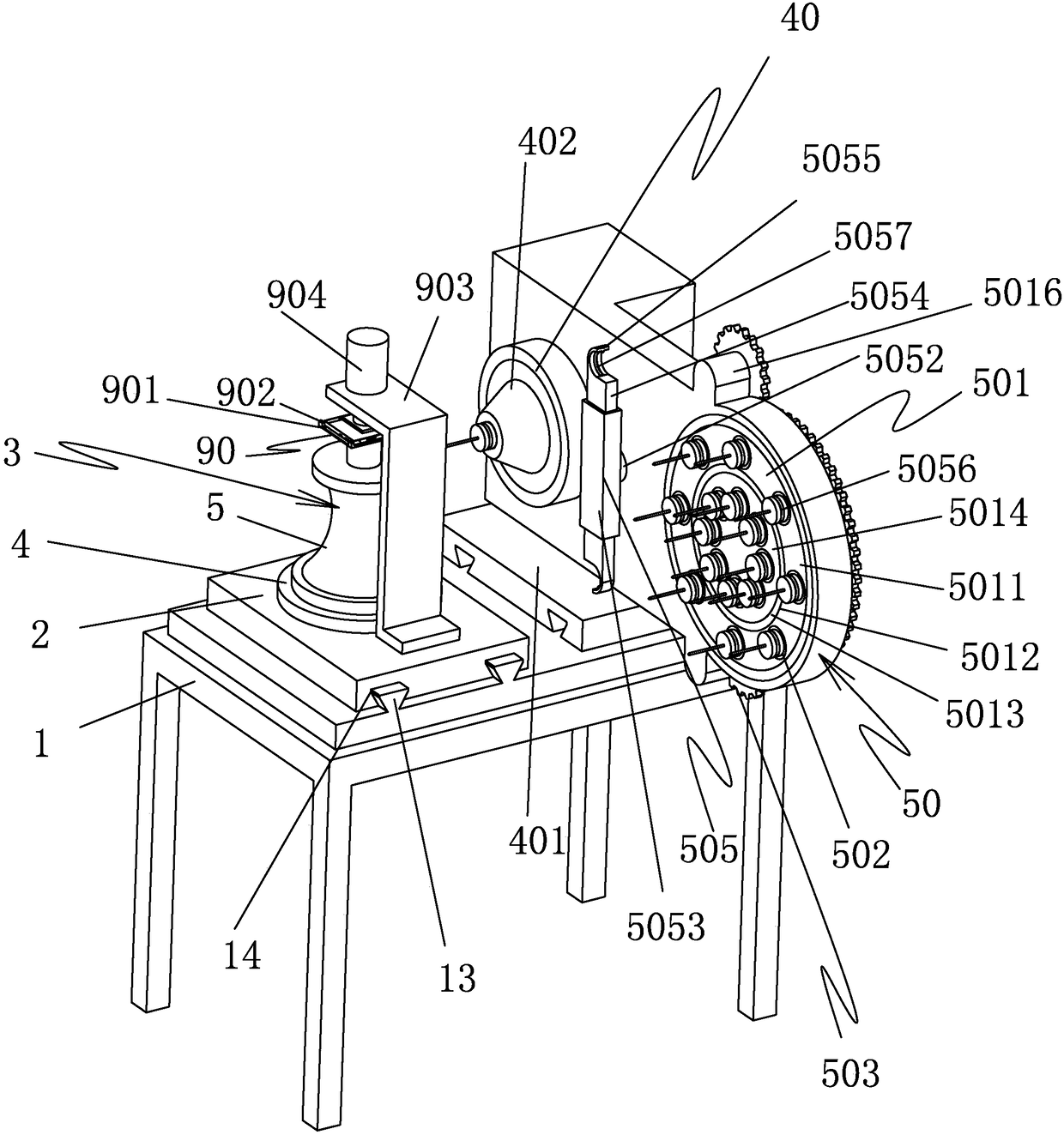

[0046] Such as figure 1 As shown, the first embodiment of the clamp device 3 of the present invention, the clamp device 3 includes a turntable 4 arranged on the clamp seat 2, a lift platform 5 is arranged on the turntable 4, and at the upper end of the lift platform 5 A positioning jig 90 is provided, and the positioning jig 90 includes a bearing platform 901. Limiting blocks 902 are respectively arranged on the four corners of the bearing platform 901, and a support 903 is placed on the clamp seat 2 on one side of the rotating disk 4. A push rod motor 904 is arranged on the support 903 , and a pressing plate is arranged on the push rod of the push rod motor 904 .

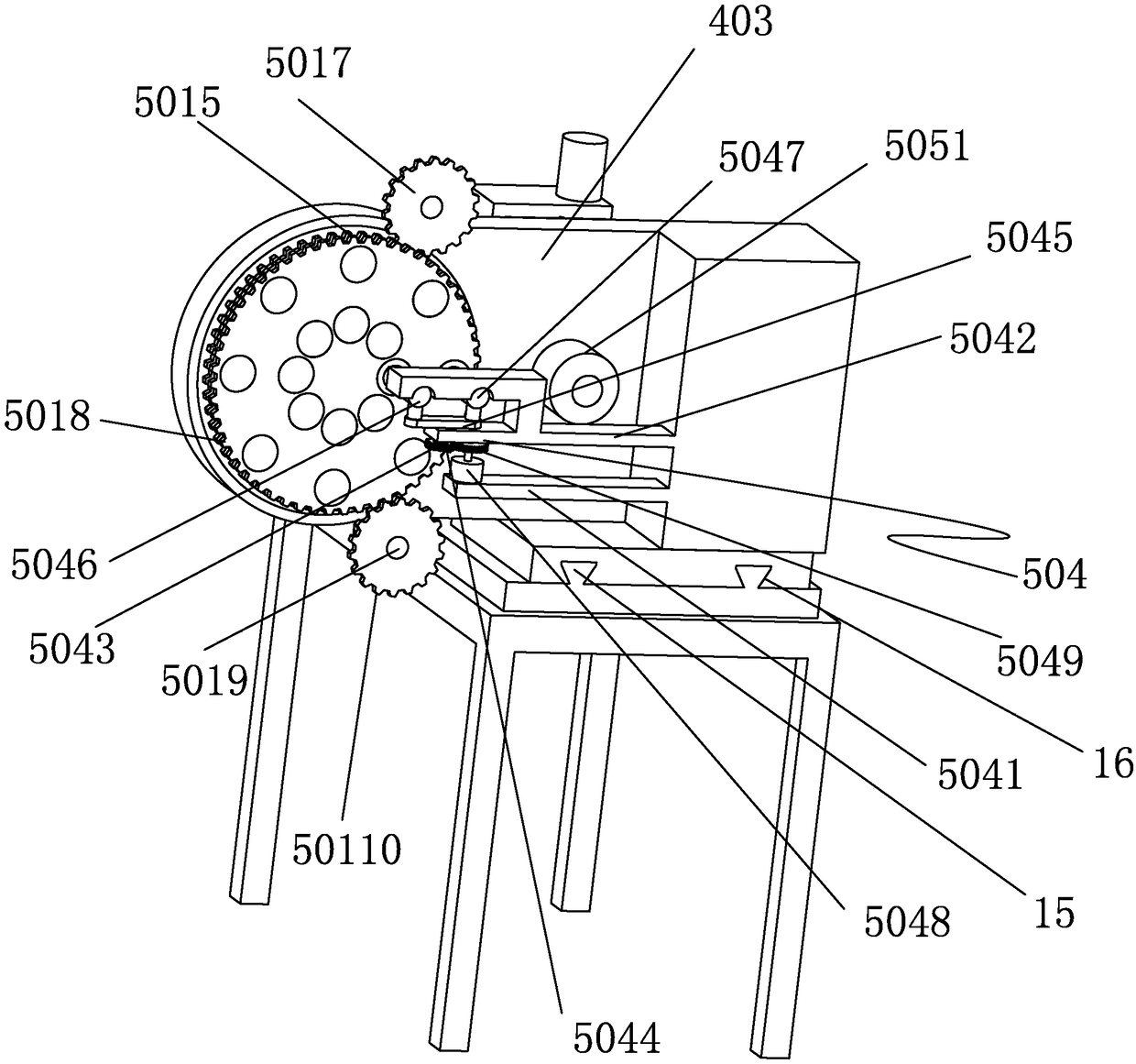

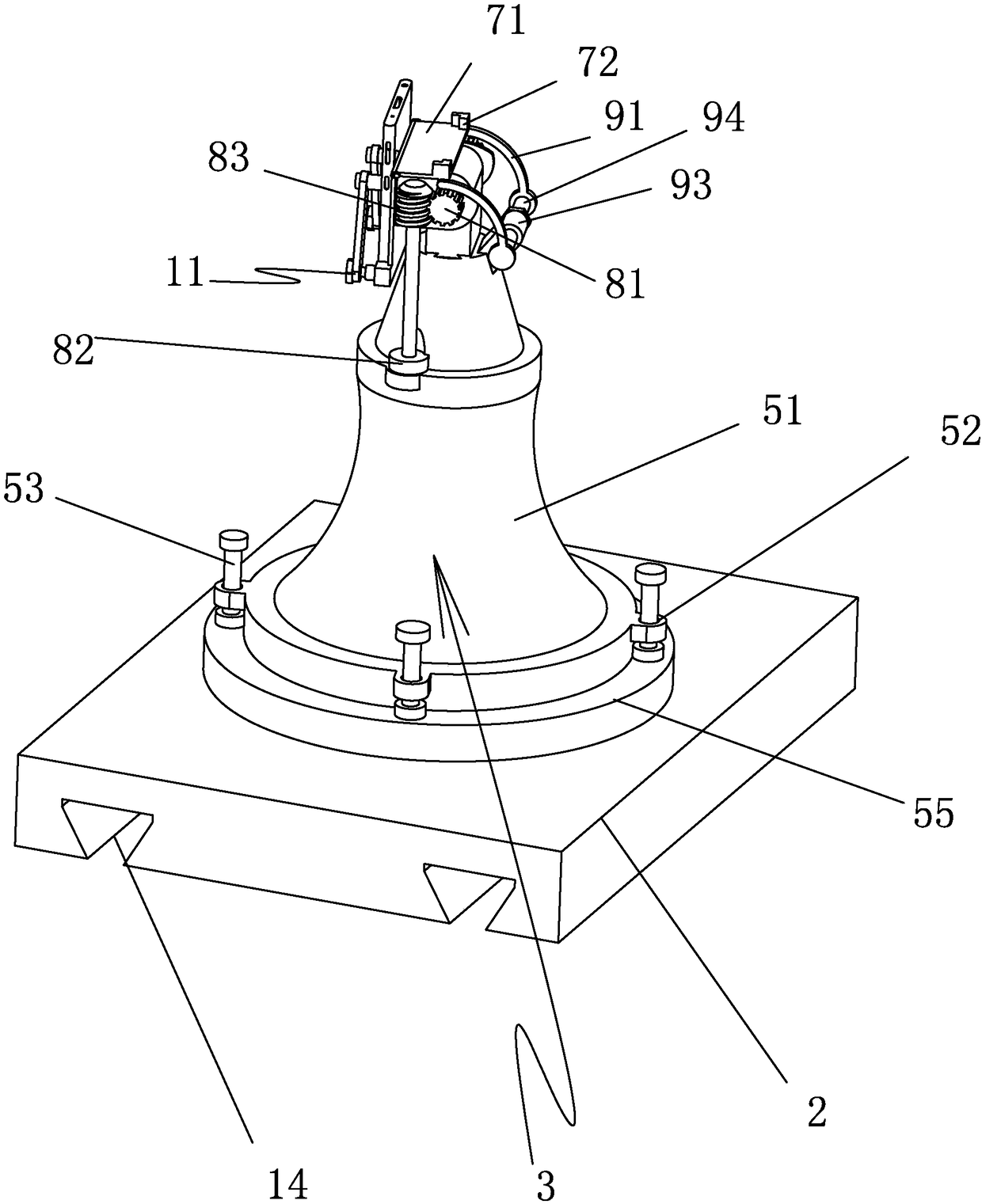

[0047] Such as Figure 3-5 As shown, the second embodiment of the clamp device 3 of the present invention, the clamp device 3 includes a turntable 4 arranged on the clamp seat 2, and a lifting platform 5 that can move up and down in relative rotation is provided on the turntable 4 , a first clamp 6 is hinged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com